يمكن تعريف قولبة حقن الأكريليك بالحقن بأنها تقنية جديدة لتصنيع المنتجات البلاستيكية بجودة عالية. ولهذه التقنية تطبيقات واسعة في صناعة السيارات وقطاع الرعاية الصحية والسلع الاستهلاكية والإلكترونيات. وتشتهر بشكل خاص بصناعة منتجات شفافة وقوية وجذابة.

تُعد الصين جزءًا رئيسيًا في مجال صناعة قوالب الأكريليك. تمتلك الصين كميات كبيرة من المصانع التي تصنع قوالب وأجزاء الأكريليك عالية الجودة. وهي توفر إنتاجًا فعالاً من حيث التكلفة ويمكن الاعتماد عليه وقابلاً للتطوير للأسواق الدولية.

تغطي هذه الورقة عملية القولبة بالحقن، وأنواع القوالب، والتطبيقات، وأفضل الممارسات في قولبة حقن الأكريليك.

ما هو قولبة حقن الأكريليك بالحقن؟

قولبة حقن الأكريليك هي تقنية لإنتاج الطائرات يتم فيها تسخين بلاستيك الأكريليك حتى يذوب ثم حقنه في قالب. يعالج البلاستيك ويتصلب في شكل معين. هذه العملية مفيدة للغاية في إنتاج أجزاء معقدة ومتسقة على نطاق واسع.

كريات الأكريليك صغيرة وتستخدم كمواد غذائية أولية. يتم سكبها في برميل ساخن حتى تذوب. ثم يتم حقن الأكريليك المنصهر في قالب عالي الضغط بقوالب الأكريليك. يتم تبريد القوالب وفتحها، ويتم إخراج المنتج النهائي.

هذه العملية سريعة ودقيقة واقتصادية على عكس طرق التشكيل الأخرى. وهي تناسب الصناعات التي تحتاج إلى كمية الإنتاج دون المساس بالضرورة بالجودة.

فوائد صب الأكريليك

هناك فوائد عديدة لقولبة الأكريليك.

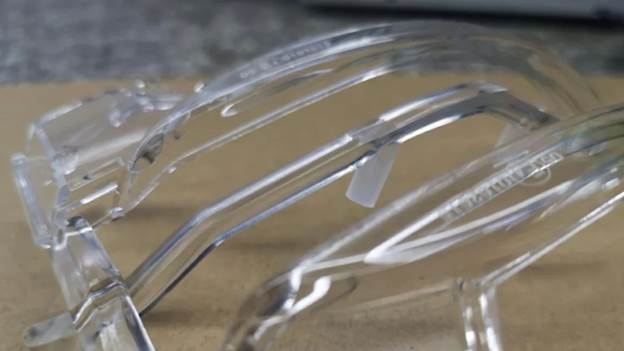

- شفافية كبيرة: منتجات الأكريليك شفافة للغاية. وكثيراً ما يتم استخدامها في الحالات التي يكون فيها من الضروري أن تكون مرئية.

- المتانة: الأكريليك متين ومقاوم للخدوش.

- الأشكال المعقدة: فهي قادرة على تنفيذ تصميمات معقدة يصعب تنفيذها باستخدام مواد بلاستيكية أخرى.

- فعالة من حيث التكلفة: بعد إنشاء القوالب، يمكن إنشاء آلاف القطع في وقت قصير، مما يجعل العملية أقل تكلفة.

- الاتساق: كل دفعة هي نفس الدفعة التي سبقتها، ويتم ضمان الجودة بكميات كبيرة.

تتميز قوالب الأكريليك بالسرعة والدقة، وبالتالي فهي خيار جيد حيثما كانت الجودة والسرعة متوقعة في الصناعات.

تم اكتشاف قولبة حقن الأكريليك بالحقن

في منتصف القرن العشرين، بدأت الشركات المصنعة للعملية في تطوير عملية قولبة حقن الأكريليك لأن الشركات المصنعة أرادت إيجاد طريقة أسرع وأكثر دقة لتشكيل PMMA. في السابق، كان يتم استخدام الصب كعملية أساسية لقولبة الأكريليك، والتي كانت عملية بطيئة ومستهلكة للعمل.

اخترع مهندسون في ألمانيا والولايات المتحدة الأمريكية في أربعينيات وخمسينيات القرن العشرين آلات يمكنها صهر كريات الأكريليك عند درجة حرارة تتراوح بين 230 و280 درجة مئوية وحقنهم في قوالب الأكريليك الصغيرة. وقد أتاح هذا الاختراع تصنيع أجزاء معقدة وعالية الجودة ذات أبعاد موحدة.

أحدثت تقنيات حقن الأكريليك لإنتاج ما يعرف اليوم بصب الأكريليك تحولاً في صناعات مثل السيارات والأجهزة الطبية والمنتجات الاستهلاكية. لم يقلل قولبة البلاستيك الأكريليكي من الوقت فحسب بل زاد من الكفاءة أيضًا، ولكنه أيضًا صنع أجزاء ذات تفاوتات ضيقة (+-0.1 مم) وتلك التي كانت شفافة بصريًا (>90% ناقل للضوء).

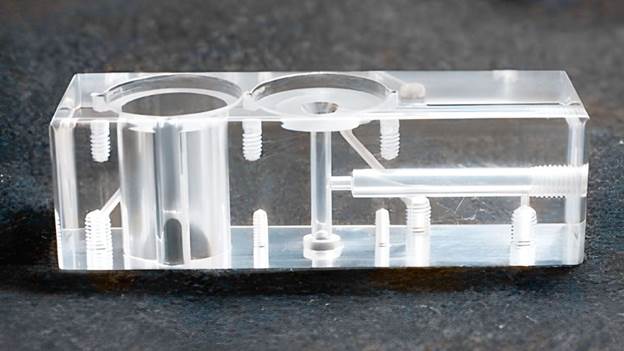

أنواع قوالب الأكريليك

هناك عدة أنواع من قوالب الأكريليك؛ حيث يتم إنتاج كل نموذج وفقًا لطبيعة الإنتاج المطلوبة ومدى تعقيد المنتج. يضمن اختيار النوع المناسب نتائج عالية الجودة والكفاءة في قولبة الأكريليك.

القوالب أحادية التجويف

تصنع القوالب أحادية التجويف لصنع جزء واحد بعد كل دورة حقن. يمكن استخدامها عندما يكون تشغيل الإنتاج صغيراً أو في المشاريع النموذجية. مع القوالب أحادية التجويف، تتم عملية قولبة مادة الأكريليك بالحقن باستخدام المصطلح قيد النظر حتى لا نضطر إلى التعامل مع مشكلة التشكيل غير الصحيح والأسطح الغامضة.

القوالب متعددة التجاويف

القوالب متعددة التجاويف قادرة على تصنيع العديد من النسخ في دورة واحدة. وهذا يمنحها ملاءمة مثالية للإنتاج الضخم. غالبًا ما يتم تشكيل القوالب متعددة التجاويف باستخدام الأكريليك لتحقيق الاتساق وتقليل وقت الإنتاج.

القوالب العائلية

في دورة واحدة، تولد القوالب العائلية بعض الأجزاء المختلفة. وهذا النوع عملي في صياغة المكونات التي تشكل تجميع المنتج. يمكن أن تستخدم القوالب العائلية صب البلاستيك الأكريليكي الذي يتيح تصنيع عدة قطع في نفس الوقت، مما يوفر الوقت والتكلفة.

قوالب العداء الساخن

تسمح قوالب العداء الساخن بحفظ البلاستيك في قنوات لتقليل الفاقد وتعزيز الكفاءة. تستخدم أنظمة العداء على الساخن قوالب الأكريليك التي تناسب المنتجات عالية الدقة ذات الأسطح الملساء والعيوب الأقل.

قوالب العدّاء البارد

تستخدم القوالب العداءة الباردة قنوات تبرد مع الجزء الذي يتم تشكيله. وهي أقل تكلفة وأسهل في الإنتاج. يفضل الكثير من المصنعين الصغار والمتوسطين استخدام قوالب الأكريليك باستخدام القوالب العداءة الباردة للقيام بإنتاجها بتكلفة منخفضة.

يتم تحديد اختيار النوع المناسب لما يسمى بقوالب الأكريليك حسب حجم الإنتاج وتصميم المنتج والميزانية. يؤدي الاختيار الصحيح للقوالب إلى أداء أفضل لقولبة حقن الأكريليك والمنتجات النهائية ذات الجودة العالية.

تقنيات قولبة البلاستيك الأكريليكي

قولبة البلاستيك الأكريليكي هي عملية استخدام عدة طرق لتحويل مواد الأكريليك إلى عناصر مفيدة وجذابة. كلتا الطريقتين لها نقاط قوة، والتي يتم تحديدها حسب التصميم وحجم الإنتاج واحتياجات المنتج.

القولبة بالحقن

وتتكون الطريقة الأكثر شيوعًا، والتي تسمى صب حقن الأكريليك بالحقن، من تسخين وحدات الأكريليك الفرعية، التي تسمى كريات الأكريليك، حتى تصبح منصهرة، ثم حقنها في قوالب الأكريليك. وعند التبريد، يتصلب البلاستيك في الشكل المقصود. هذه هي أفضل طريقة لصنع منتج عالي الدقة بكميات هائلة.

القولبة بالضغط

يتم وضع صفائح الأكريليك في قالب ساخن وضغطها لتشكيلها في قالب ضغط. يمكن تطبيق هذه التقنية على المقاطع السميكة والتصاميم العادية. يُستخدم القولبة بالضغط للأكريليك لجعلها متجانسة في السُمك والقوة.

البثق

تُصنع المقاطع الجانبية الطويلة المتواصلة عن طريق البثق، حيث يتم دفع الأكريليك المنصهر في قالب مُشكَّل. عن طريق البثق، يتم استخدام قولبة الأكريليك في عناصر مثل الأنابيب والقضبان والصفائح. وهي متساوية في المقاطع العرضية والأسطح.

التشكيل الحراري

تعمل تقنية التشكيل الحراري على تسخين ألواح الأكريليك حتى تصبح مرنة وتشكيلها فوق قالب باستخدام التفريغ أو الضغط. يعمل هذا الأسلوب بشكل جيد مع المنتجات الضخمة أو غير الضخمة. التشكيل الحراري هي تقنية لتصنيع قوالب بلاستيك الأكريليك ذات الأحجام المنخفضة إلى المتوسطة من الأكريليك بتكلفة منخفضة بشكل معقول.

القوالب الدورانية

يُستخدم القولبة الدورانية أيضًا مع الأكريليك، ولكن يتم تدوير القالب أثناء التسخين لتغطية القالب من الداخل بالتساوي. يمكن صنع الأشكال ذات التجاويف بفعالية باستخدام هذه التقنية. في القوالب الدورانية، هناك مرونة في قولبة الأكريليك لتناسب بعض التصميمات.

عملية قولبة الأكريليك

يُعد قولبة الأكريليك عملية مهمة وتقنية يتم من خلالها تغيير مادة الأكريليك الخام إلى أجزاء نهائية ذات جودة عالية. تأتي هذه العملية مع عدة عمليات، وتستلزم كل عملية تحكم دقيق في درجة الحرارة والضغط والوقت لتوفير النتيجة المثلى في عملية قولبة الأكريليك.

إعداد المواد

يبدأ التفاعل بكريات أكريليك عالية الجودة، والتي يمكن أن تكون بأحجام مختلفة (عادةً ما يكون قطرها 2-5 مم). وينبغي أن يكون محتوى الرطوبة في الكريات أقل من 0.2، وأي رطوبة إضافية قد تؤدي إلى ظهور فقاعات في عملية التشكيل. عادةً ما يتم تجفيف الكريات في مجفف قادوس عند درجة حرارة 80-90 درجة مئوية في مدة لا تقل عن 2-4 ساعات قبل الاستخدام.

الذوبان والحقن

يتم إدخال الكريات المجففة في برميل ماكينة القولبة بالحقن. يتم الحفاظ على درجة حرارة البرميل عند درجة حرارة 230-280 درجة مئوية، مع درجة أكريليك حسب الدرجة المستخدمة. يتم صهر الكريات بواسطة آلية اللولب لتشكيل خليط أكريليك متجانس في شكل منصهر.

يتم حقن الأكريليك بعد ذلك بضغط عالٍ - عادةً 70-120 ميجا باسكال - في قوالب الأكريليك بمجرد ذوبانها. يعتمد وقت الحقن على حجم الجزء، حيث تستغرق الأجزاء الصغيرة إلى المتوسطة حوالي 5 إلى 20 ثانية.

التبريد

يتم وضع قالب مضغوط بعد الحقن حيث يبرد الأكريليك ويحدث التصلب. يختلف وقت التبريد باختلاف سُمك الأجزاء:

- سمك 1-2 مم: 15-20 ثانية

- سمك 3-5 مم: 25-40 ثانية

- أكثر من 5 مم فوق سمك 5 مم: 45-60 ثانية

التبريد ضروري لإزالة الاعوجاج أو الانكماش أو العيوب السطحية. قد تستفيد القوالب المنشأة أيضًا من أنابيب المياه أو التبريد بالزيت للحفاظ على درجات الحرارة بالمواصفات المطلوبة.

فتح القالب وقذفه

يتم فتح القالب بمجرد أن يبرد، ويتم إخراج الجزء باستخدام دبابيس قاذف ميكانيكية أو هيدروليكية. وتجدر الإشارة إلى أن قوة الإخراج يجب أن تكون محدودة لضمان عدم إتلاف السطح أو تشويهه.

المعالجة اللاحقة

قد يخضع الجزء أيضًا لإجراءات تشطيب مثل قص الجزء أو صقله بعد طرده أو تلدينه. يساعد التقادم في درجات حرارة تتراوح بين 80-100 درجة مئوية إلى ساعتين أو ساعتين من التقادم في إزالة الضغوط الداخلية وتعزيز النقاء والقوة.

فحص الجودة

يتم فحص المكونات الفردية للتأكد من عدم وجود عيوب مثل فقاعات الهواء والالتواء والأبعاد. يتم استخدام الفرجار، أو إجراء مسح بالليزر، ويُسمح بأن يكون التفاوت المسموح به في حدود + 0.1 مم عند التعامل مع المكونات عالية الدقة. كما أن استخدام صب البلاستيك الأكريليكي ذي الجودة العالية يضمن أن تكون جميع منتجاتها مطابقة لمعايير الصناعة.

ملخص معلمات العملية:

| الخطوة | المعلمة | القيمة |

| التجفيف | درجة الحرارة | 80-90°C |

| التجفيف | المدة | 2-4 ساعات |

| درجة حرارة البرميل | ذوبان الأكريليك | 230-280°C |

| ضغط الحقن | 70-120 ميجا باسكال | |

| وقت التبريد | 1-2 مم | 15-20 ثانية |

| وقت التبريد | 3-5 مم | 25-40 ثانية |

| وقت التبريد | >أكثر من 5 مم | 45-60 ثانية |

| التلدين | درجة الحرارة | 80-100°C |

| التلدين | المدة | من ساعة إلى ساعتين |

| تفاوت الأبعاد | ± 0.1 مم |

يضمن قولبة الأكريليك بالخصائص التكنولوجية التالية جودة ودقة وكفاءة كل منتج. يمكن استخدام عملية قولبة حقن الأكريليك لتصنيع مكونات واضحة ومتينة ودقيقة الأبعاد باستخدام ظروف محسّنة تضمن إنتاجًا متسقًا للمكونات.

استخدامات قولبة حقن الأكريليك بالحقن

يتم تطبيق قولبة حقن الأكريليك بالحقن بكثافة في القطاعات التي تتطلب الدقة والوضوح وطول العمر.

صناعة السيارات

تُصنع المصابيح الخلفية ولوحات العدادات والزخارف نتيجة لقوالب الأكريليك. تتراوح سماكة الأجزاء عادةً بين 1.5 و5 مم، وتتراوح درجة حرارتها بين -40 درجة مئوية و80 درجة مئوية. يتم ضمان النقاء وطول العمر من خلال صب الأكريليك.

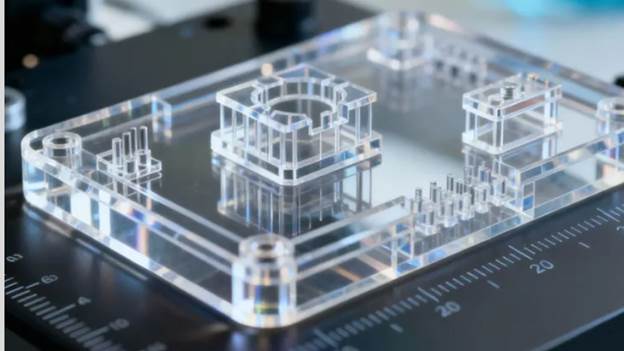

الرعاية الصحية والمعدات الطبية.

يتم تصنيع معدات المختبرات وأغطية الأدوات والدروع الواقية عن طريق عملية صب البلاستيك الأكريليكي. هناك متطلبات لأجزاء ذات تفاوتات تفاوت تبلغ +-0.1 مم وإمكانية تعقيمها. يضمن القولبة بحقن الأكريليك أسطحًا ناعمة وصحيحة.

الإلكترونيات الاستهلاكية

أغطية الهواتف الذكية وأغلفة مصابيح LED والشاشات الواقية مصبوبة من الأكريليك. يجب أن يكون للجزء لمعان على السطح يتجاوز 90% وأبعاد دقيقة.

الأمفيتامين والميثامفيتامين والأمفيتامينات في المنتجات المنزلية ومنتجات الزينة.

يتم تصنيع منتجات مثل حاويات مستحضرات التجميل وحافظات العرض والألواح بمساعدة استخدام ما يسمى بصب البلاستيك الأكريليكي. يتراوح متوسط سمكها بين 2 و8 مم، مما يوفر تشطيبات متساوية مع تشطيبات ناعمة وشفافة وملونة.

المكونات الكهربائية والإضاءة والبصريات.

يُستخدم قولبة حقن الأكريليك في صفاء عدسات LED وناشرات الضوء واللافتات. تحقق هذه الأجزاء نفاذاً للضوء يصل إلى أكثر من 90% عند زوايا وسُمك محددين.

معدات صناعية

هناك استخدام واقيات الماكينات وألواح العدادات والحاويات الشفافة التي تعتمد على صب الأكريليك. تتطلب المكونات قوة صدم تتراوح بين 15-20 كيلو جول/م2 وأن تكون شفافة.

التطبيقات النموذجية

يتم تطبيق هذا الإطار في الحالات التي تتحكم فيها الحكومة في جميع السمات الرئيسية لخدمات الرعاية الصحية، مثل الجودة والتكلفة وإمكانية الوصول إلى الخدمات المقدمة.

الصناعة

- أمثلة على المنتجات

- المواصفات الرئيسية

- السيارات

- المصابيح الخلفية ولوحات العدادات

- السُمك 1.5-5 مم، درجة الحرارة من 40 درجة مئوية إلى 80 درجة مئوية

الرعاية الصحية

- رفوف أنابيب الاختبار، والدروع

- تحمل -0.1 مم، مقاوم للتعقيم.

الإلكترونيات

- الأغطية، العلب والأغطية

- لمعان السطح 90، ثبات الأبعاد.

السلع الاستهلاكية

- الحاويات التي تحتوي على مستحضرات التجميل وصناديق العرض.

- سُمك 2-8 مم، طبقة نهائية ناعمة

- الإضاءة

- عدسات LED، ناشرات الصمامات الثنائية الباعثة للضوء (LED)

- انتقال للضوء أكبر من 90، وهندسة دقيقة.

- صناعي

- الحراس، الحاويات

- قوة الصدم 15-20 كيلوجول/م2، واضح.

مراقبة جودة قولبة الأكريليك

في قولبة الأكريليك، الجودة ضرورية من أجل الحصول على أجزاء ترقى إلى المستوى القياسي. يمكن أن يكون لبعض العيوب الطفيفة تأثير على الأداء والمظهر.

فحص الأجزاء

يتم فحص جميع المكونات ضد فقاعات الهواء والانحناءات والخدوش على السطح. يتم استخدام الفرجار أو الماسحات الضوئية الليزرية للقياس بحيث لا يتم تجاوز التفاوت المسموح به بمقدار +-0.1 مم. تعتمد عملية قولبة حقن الأكريليك بالحقن على الفحوصات المنتظمة كوسيلة لضمان الجودة العالية للمخرجات.

صيانة العفن

يتم منع العيوب وإطالة عمر القالب من خلال ضمان تنظيفه وفحصه بانتظام. قد تؤدي القوالب القديمة إلى عدم الدقة في الأبعاد أو الأسطح غير المستوية.

مراقبة العمليات

يتم فحص درجة الحرارة والضغط وأوقات التبريد باستمرار أثناء عملية صب الأكريليك. يتراوح متوسط درجات حرارة البرميل بين 230 و280 درجة مئوية ويتراوح ضغط الحقن بين 70 و120 ميجا باسكال، لتجنب الأخطاء.

الاختبار النهائي

يتم اختبار المكونات الكاملة من خلال الاختبارات الوظيفية والبصرية. وعلى سبيل التوضيح، يجب فحص المكونات البصرية فيما يتعلق بنقل الضوء (أكبر من 90 في المائة) والأجزاء الهيكلية فيما يتعلق بقوة الصدم (15-20 كيلوجول/م2).

ويمكن تحقيق ذلك من خلال ضبط جودة المنتج النهائي بإحكام من أجل إنتاج أجزاء فردية من صب البلاستيك الأكريليكي يمكن الاعتماد عليها ودقيقة وخالية من العيوب الجمالية.

اختيار تحالف حقن حقن صب الأكريليك المناسب

عندما يتعلق الأمر بالإنتاج عالي الجودة، فإن الاختيار الصحيح للشركة المصنعة لقولبة حقن الأكريليك أمر بالغ الأهمية.

الخبرة والخبرة

ابحث عن شركاء لديهم خبرة في قولبة الأكريليك وصب الأكريليك. سيتمكن المهندسون ذوو الخبرة من تحقيق أقصى قدر من تصميم القالب والحقن والتشطيب حسب المواصفات.

المعدات والتكنولوجيا

تُعد الماكينات المبتكرة التي تنظم درجة الحرارة (230-280 درجة مئوية) وضغط الحقن (70-120 ميجا باسكال) محددة للغاية في تعزيز اتساق المنتج. يتم تقليل الأخطاء والهدر بمساعدة قوالب الأكريليك عالية الجودة والأنظمة الآلية.

ضمان الجودة

عندما يتعلق الأمر بمورد موثوق به، فإنه يتضمن فحوصات صارمة لأجزائه، مثل فحوصات الأبعاد (في حدود -0.1 مم) وفحوصات السطح. ومن خلال ضمان الجودة الصحيح، يتم التأكد من أن مكونات بلاستيك الأكريليك ستكون واضحة ومتينة وخالية من العيوب.

التواصل والدعم

يتفاعل المصنعون الجيدون أثناء عملية التصميم والتصنيع. فهي تساعد في تحسين القوالب، واقتراح المواد، وتحسين زمن دورة المواد.

اقتراحات بشأن القوالب الأكريليك الناجحة

يُنصح باتباع أفضل الممارسات في قولبة الأكريليك للحصول على قطع عالية الجودة ودقيقة ومتينة.

استخدام مواد عالية الجودة

ابدأ باستخدام كريات أكريليك بحجم 2-5 مم ذات محتوى رطوبة أقل من 0.2. يساعد التجفيف عند درجة حرارة 80-90 درجة مئوية من 2-4 ساعات في التخلص من الفقاعات والعيوب السطحية عند قولبة الأكريليك.

تحسين تصميم القالب

إنشاء تصميم مناسب للتهوية وتصميم قوالب أكريليك ذات قنوات تبريد ونقاط حقن مناسبة. يقلل من الالتواء والانكماش وزمن الدورة في عملية قولبة الأكريليك بالحقن.

بارامترات عملية التحكم

حافظ على درجة حرارة البرميل عند 230-280 درجة مئوية وضغط الحقن عند 70-120 ميجا باسكال. يجب أن يكون وقت التبريد مكافئًا لسمك الجزء:

- 1-2 مم - 15-20 ثانية

- 3-5 مم - 25-40 ثانية

- 5 مم - 45-60 ثانية

الفحص بانتظام

فحص أبعاد الأجزاء (الحد الأقصى للخطأ في الأبعاد 0.1 مم)، والبقع الضوئية، والوضوح البصري (الإرسال أكبر من 90%). تكمن ميزة صب البلاستيك الأكريليكي في القدرة على إجراء فحص متسق.

الحفاظ على القوالب

غسل القوالب وتنظيفها لتجنب التآكل وضمان إنتاج سلس ومتسق. يجد الأكريليك المقولب من الأكريليك زيادة الكفاءة وجودة الأجزاء.

ستعطي كل هذه النصائح عملية قولبة حقن الأكريليك مكونات أكيدة ولا تقل جاذبية وصحيحة تمامًا في كل مرة.

العيوب المنتشرة على نطاق واسع والوقاية منها

يمكن أن تحدث عيوب حتى في حالة قولبة حقن الأكريليك الدقيقة. معرفة الأسباب والحلول تضمن جودة صب الأكريليك.

فقاعات الهواء

قد ينتج أي هواء موجود في قوالب الأكريليك فقاعات على السطح.

التوصية: تجفيف الأكريليك NP بنسبة رطوبة أقل من 0.2 في المائة، والتهوية الصحيحة للقوالب، وضغط حقن 70-120 ماكي.

الالتواء

يحدث الالتواء، حيث لا تبرد الأجزاء بشكل متساوٍ، ومن ثم تكون مشوهة.

القرار: قنوات تبريد متجانسة، ودرجة حرارة الجزء، ووقت تبريد الجزء اعتمادًا على سُمك الجزء (على سبيل المثال، 1-2 مم - 15-20 ثانية، 3-5 مم - 25-40 ثانية).

علامات الحوض

تتشكل علامات الحوض عندما تتقلص الأجزاء السميكة أثناء التبريد.

الحل: تعظيم سمك الجدار، وضغط التعبئة، ومعدلات التبريد الكافية في صب الأكريليك.

اللقطات القصيرة

تحدث الطلقات القصيرة عندما يفشل الأكريليك المنصهر في ملء القالب.

القرار: قم بتشغيل المزيد من الضغط في مكبس الحقن، وأزل الانسدادات في قوالب الأكريليك، وتحقق من درجة حرارة البرميل الصحيحة (230-280 درجة مئوية).

عيوب السطح

الخدوش الخشنة أو الخدوش تقلل من الشفافية في صب البلاستيك الأكريليكي.

العلاج: قم بتلميع القوالب، ولا تستخدم الكثير من قوة الطرد، وحافظ على نظافة مناطق المعالجة.

النظرة المستقبلية لقولبة حقن الأكريليك بالحقن

التكنولوجيا، والكفاءة، والاستدامة هي مستقبل قولبة حقن الأكريليك.

الأتمتة المتقدمة

أصبحت عملية قولبة الأكريليك مؤتمتة وروبوتية أكثر فأكثر. يمكن التحكم في درجات الحرارة (230-280 درجة مئوية) وضغوط الحقن (70-120 ميجا باسكال) بدقة بواسطة الماكينات. تقلل الأتمتة في إنتاج الأكريليك عن طريق التشكيل الآلي من الأخطاء البشرية وتعزز من أوقات الدورات.

الطباعة ثلاثية الأبعاد والنماذج الأولية

يتم إنجاز القوالب في النموذج الأولي من الأكريليك عن طريق الطباعة ثلاثية الأبعاد خلال فترة زمنية محدودة. وهذا يسمح للمهندسين بإجراء التجارب على التصميمات وتحسين القوالب قبل أن يتم الإنتاج بالكامل. كما أن صب البلاستيك الأكريليكي أسرع وأرخص بسبب سرعة إنجاز النماذج الأولية.

مواد مستدامة

أصبح من المعتاد إعادة تدوير نفايات الأكريليك وتطوير مواد صديقة للبيئة. ستؤدي الكريات المعاد تدويرها في إنتاج منتجات الأكريليك في إطار عملية القولبة بالحقن إلى تقليل الأثر البيئي، على الرغم من أنها لن تؤثر على جودة المنتج.

تحسين جودة المنتج

في المستقبل، سيكون هناك المزيد من الوضوح البصري (>90 في المائة من انتقال الضوء)، والسطح النهائي، والتحكم في الأبعاد (+-0.1 مم) فيما يسمى صب الأكريليك. يعمل ذلك على تقوية المنتجات، مما يجعلها أكثر وضوحًا ودقة.

نمو الصناعة

مع تزايد الحاجة إلى منتجات متينة وخفيفة الوزن وشفافة، سيتوسع السوق في أنشطة صب الأكريليك في قطاعات السيارات والقطاعات الطبية والإلكترونية والسلع الاستهلاكية.

من خلال اعتماد التكنولوجيا والاستدامة، سيظل قولبة حقن الأكريليك بالحقن إحدى عمليات التصنيع المستخدمة في الإنتاج عالي الجودة والكفاءة.

Sincere Tech: مزودك الموثوق لقولبة حقن الأكريليك.

تقدم شركة Sincere Tech (Plas.co) خدمات صب البلاستيك الدقيق والأكريليك القولبة بالحقن, التي يمكن الوثوق بها. لدينا قطع قوية ودقيقة وجذابة، وهي مضمونة من خلال التكنولوجيا العالية والقوى العاملة الماهرة لدينا. نحن نتعامل مع قوالب وحلول الأكريليك المصنوعة خصيصًا والتي نصنعها وفقًا لمواصفات التصميم الخاص بك.

حلول مفيدة وجديرة بالثقة.

نقوم بتنفيذ نموذج أولي شامل وتصميم المنتج حتى الإنتاج على نطاق واسع. ستتعامل مع قطع عالية الجودة ومتينة وموثوقة بين أيدينا بفضل خبرتنا في قولبة الأكريليك وصب الأكريليك.

سبب اختيار Sincere Tech (Plas.co)؟

يمكن الاطلاع على أمثلة عملنا على https://plas.co. إذا كنت تبحث عن الأفضل من حيث الجودة والدقة والخدمة الجيدة، فإن Sincere Tech (Plas.co) هي شريكك عندما تبحث عن الأفضل في حلول التشكيل.

الخاتمة

يُعد قولبة الأكريليك وقولبة حقن الأكريليك من العمليات الأساسية في الإنتاج الحالي. فهي توفر منتجات عالية الجودة وطويلة الأمد وعصرية يمكن استخدامها في معظم الصناعات. وهي تتسم بالكفاءة والموثوقية، بدءًا من تصميم قوالب الأكريليك، إلى إنشاء الأجزاء المتناسقة.

عندما يلتزم المصنعون بأفضل الممارسات ويختارون الشريك المناسب، يمكن إنتاج منتجات عالية الجودة بمساعدة استخدام صب الأكريليك. يعني النضج الإضافي للتكنولوجيا أن قولبة حقن الأكريليك بالحقن ستكون واحدة من أهم المنتجات في تطوير منتجات مبتكرة ودقيقة وجمالية.