Forskelle og ligheder mellem overstøbning og indsatsstøbning: sammenligning og anvendelser

Valget af den rigtige støbeproces spiller en meget afgørende rolle i produktionsverdenen. To af de mest almindelige teknikker er overstøbning og indsætningsstøbning. Hver af dem har sine stærke sider, anvendelser og udfordringer. Forskellene kan være tidsbesparende og omkostningsbesparende, hvilket er tilfældet, når man skal vælge mellem dem. Når det gælder fremstilling af produkter, afhænger fremstillingen af produktet af brugen af den rigtige støbeproces for at bestemme produktets kvalitet og effektivitet. Disse to er overstøbning og indsætningsstøbning. På trods af at de begge bruger flere materialer, anvendes de til forskellige formål.

Overstøbning fokuserer på komfort, udseende og soft touch-overflade, mens indsatsstøbning er baseret på styrke, holdbarhed og mekaniske bindinger. Erfaringen med forskellen, fordelene og anvendelsen af disse metoder gør det muligt for producenterne at træffe gode beslutninger. Følgende artikel behandler de vigtigste punkter, som design, omkostninger, produktionstid og fremtidige tendenser, som kan gøre det muligt for fagfolk at vælge mellem insert mold og overmold, og hvordan de kan producere deres varer på den mest hensigtsmæssige måde.

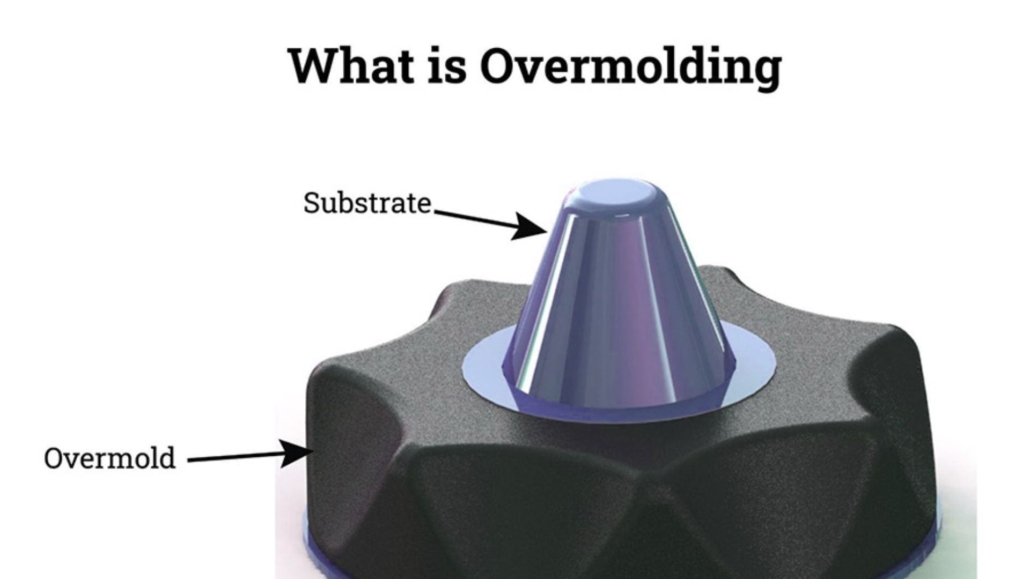

Hvad er overstøbning?

Ved overstøbning skabes en komponent ved at bruge to eller flere forskellige materialer. En substratbase er generelt formet. Det bliver derefter støbt med et sekundært materiale over eller omkring det. Det giver producenterne mulighed for at blande materialer med forskellige egenskaber, f.eks. stivhed og fleksibilitet.

Soft-touch-produkterne er typisk overstøbte, herunder greb på værktøj, tandbørster eller andre elektroniske genstande. Det øger skønheden, komforten og funktionaliteten.

Overstøbning har et par væsentlige ulemper, som omfatter:

- Mere ergonomisk og behagelig for brugeren.

- Højere levetid for produkterne.

- Mere fleksibilitet i designet.

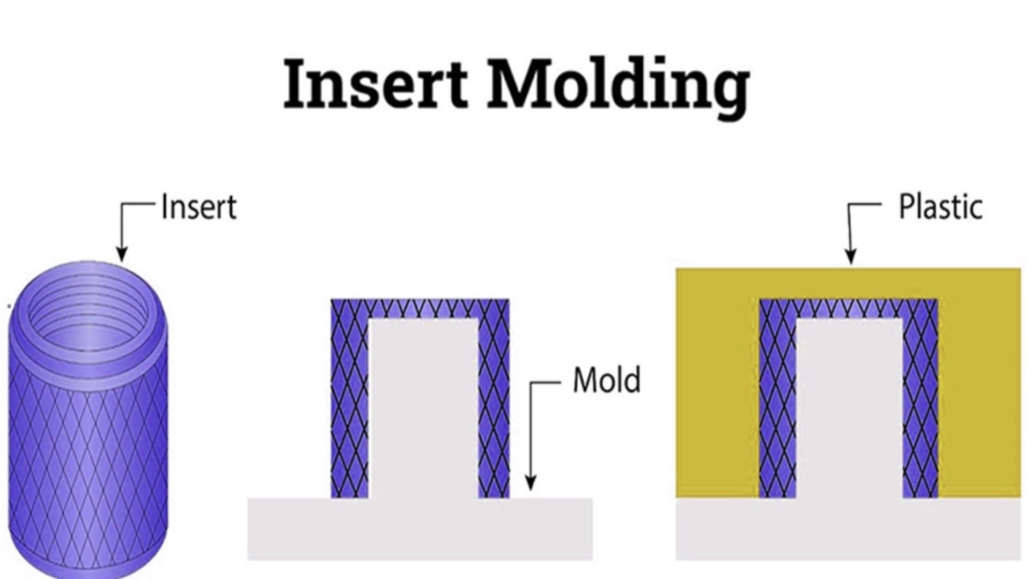

Hvad er indsætningsstøbning?

Indsatsstøbning: Dette er en proces, hvor en præformet komponent indsættes i en form, og plast sprøjtes ind i delen. Indsatsen kan være af metal, plast eller et andet materiale. Det færdige produkt har den tilpassede indsatsform.

Indsatsstøbning er den støbning, der i vid udstrækning bruges i industrier, hvor der kræves høje mekaniske bindinger. Elektriske stik, bildele og hardwarekomponenter er nogle af de ting, der har tendens til at være afhængige af denne teknik.

Fordelene ved indsatsstøbning er:

- Stærk mekanisk binding

- Reduceret montagetid

- Evnen til at forene forskellige materialer.

Nogle eksempler på overstøbning og indsætningsstøbning

Det drejer sig om overstøbning og indsatsstøbning, som finder bred anvendelse i fremstillingsprocessen, selv om de bruges i forskellige applikationer med hensyn til produkternes særlige egenskaber. Deres forståelse af deres anvendelser vil hjælpe producenterne med at vælge den rigtige proces.

Anvendelser Overstøbning er blevet anvendt som følger

Overstøbning er velegnet til produkter, der skal være komfortable, smukke eller gribevenlige. Det er en kombination af både bløde og hårde materialer, der anvendes i en enkelt funktionel del. Almindelige anvendelser er:

- Værktøjsgreb: Håndtagene er mere ergonomiske og lavet af overhærdet plast.

- Forbrugerelektronik: Bløde trykknapper på ting som fjernbetjeningen og hovedtelefonerne.

- Medicinsk udstyr, Medicinsk udstyr: Sikkerhed og komfort. Sprøjter eller kirurgisk udstyr har gummibelagte overflader.

- Bildele: Gummipakninger eller tætninger til plastdelene for at minimere støj og forbedre holdbarheden.

Følgende applikationer er blevet udført under Insert Molding

Begrundelsen for at bruge en indsatsstøbning er, at produktet kræver høj mekanisk styrke, eller at det er en kombination af forskellige materialer i én enhed. Det anvendes i almindelige applikationer som f.eks:

- Elektriske stik: PT består af former, der indeholder metalindsatser, som skal indsættes i plastlegemer.

- Dele til biler: Motordele eller beslag, hvor der skal laves metalindsatser for at styrke plasten.

- Hardware-løsninger: Skruer eller metalgenstande er inkluderet i plastikstykkerne for at gøre dem nemme at sætte sammen.

- Industrielt udstyr: Maskindele, der omfatter både metalindsatser og formstøbt plast, der skal bruges i dele med høj belastning.

Den enkeltes valg mellem de to processer afhænger af målet med produktet. Det skal overstøbes i tilfælde af overkomfort, greb eller blød berøringsoverflade. Hvis problemer med styrke, holdbarhed og mekanisk stabilitet er af stor betydning, skal man anvende indsatsstøbning.

Konceptet med disse applikationer vil hjælpe med at opnå fordelene ved den såkaldte overmolding og insert moulding inden for moderne produktion.

Væsentlige forskelle mellem overstøbning og indsatsstøbning

Selv om de to metoder indebærer brug af materialer, er der tydelige forskelle. Her er en detaljeret sammenligning:

| Funktion | Overstøbning | Indsatsstøbning |

| Proces | Støber et sekundært materiale over et basissubstrat | Injicerer plast omkring en præformet indsats |

| Materialer | Kombinerer ofte blød og hård plast | Kan kombinere plast med metal, plast eller andre komponenter |

| Anvendelser | Greb, håndtag, forbrugerelektronik | Elektriske stik, bilindustrien, hardware |

| Kompleksitet | Lidt mindre kompleks | Kræver præcis placering af indsatser |

| Styrke | Fokus på komfort og æstetik | Fokus på mekanisk styrke og holdbarhed |

Det er en sammenligning, man skal foretage, når man skal vælge mellem en indsatsform og en overform. Overmoldingen er optimeret i forhold til brugeroplevelsen, og indsatsstøbningen er også optimeret i forhold til den strukturelle integritet.

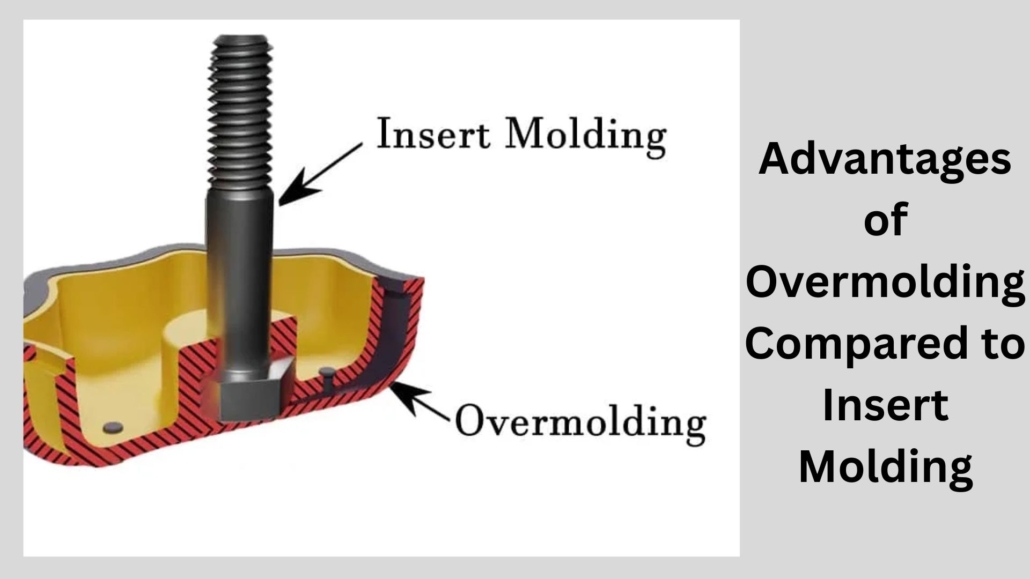

Fordele ved overstøbning sammenlignet med indsætningsstøbning

Når man sammenligner overmold med insert mold, skal man kende fordelene ved hver proces. De to er gode på mange måder, men begge processer giver mulighed for at kombinere materialer.

Fordele ved overstøbning

- Øget ergonomi: Behagelige greb og håndtag på hårde overflader er bløde.

- Bedre æstetik: Overstøbning betyder, at farverne og strukturerne kan blandes, så de fremstår i høj kvalitet.

- Hurtigere montering: En række dele kan samles samtidigt, hvilket sparer tid.

- Fleksibilitet i designet: Funktionaliteten og de visuelle effekter kan opnås ved hjælp af en række forskellige materialer.

- Øget brugervenlighed: Fungerer bedst, når produktet kræver en blød berøring, f.eks. tandbørster, værktøj og elektronik.

Opnåelse af fordelene ved indsætningsstøbning

- Kraftig mekanisk binding: Indsatser som metaller og hård plast er permanent integreret i støbeproduktet.

- Holdbarhed: Dele kan stresses og udsættes for enorme mekaniske belastninger til bristepunktet.

- Mindre montering: Indsatserne er støbt og eliminerer dermed behovet for montering efter produktionen.

- Tillader komplekse mønstre: Designet er ideelt: Når der er flere materialer, der skal være strukturelt sunde i produktet.

- Præcision og pålidelighed: De bedste anvendelsesmuligheder er inden for industri, elektronik og køretøjskomponenter.

Bevidstheden om disse fordele vil vejlede producenterne, når de skal træffe beslutninger, f.eks. om det bedste af de to alternativer: indsatsstøbning og overstøbning. Overstøbning er bedst, hvis det er komfort, design og æstetik, det drejer sig om. Indsatsstøbning er bedre, hvis styrke, holdbarhed og mekanisk ydeevne er af større betydning.

Det kan konkluderes, at processen enten kan oversprøjtes eller indsættes, og virksomhederne kan vælge den passende for at reducere omkostningerne, spare tid og øge varernes kvalitet.

Overvejelser om design

Det er meget afhængigt af design, når der skal træffes beslutning om enten indsatsstøbning eller overstøbning. Kvalitetsplanlægning sikrer også kvalitetsproduktion, færre fejl og maksimal udnyttelse af fordelene ved enhver proces.

Materialekompatibilitet

Når man bruger overmolding, er det nødvendigt at vælge materialer, der binder til hinanden. Forkert matchning af materialerne kan resultere i delaminering eller sårbarhed. På samme måde er det vigtigt at sikre, at tryk og temperatur ligger inden for indsatsmaterialets rækkevidde under støbningsprocessen. Det er en meget vigtig procedure i sammenligningen af overstøbning og indsatsstøbning.

Tykkelse og lagdækning

Ved overstøbning skal basen have en passende tykkelse, og overstøbningsmaterialet skal bruges til at sikre, at det ikke vrider sig, samt til at sikre, at det er holdbart. Ved indsatsstøbning er det meningen, at hele indsatsen skal omsluttes af formen for at give den mekanisk styrke og en god binding. Tykkelsen af de korrekte lag er nyttig i de vellykkede projekter med indsatsformen vs overmold.

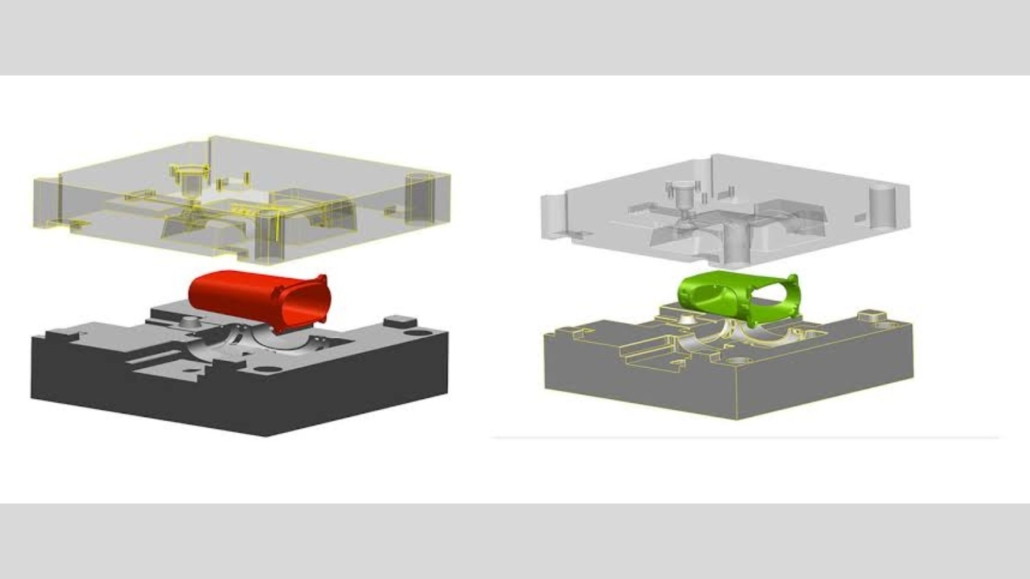

Formdesign

En form er skabt på en sådan måde, at det er nemt at udtage delene og forhindre stress på materialerne. Når der er mulighed for overstøbning, skal formen være af en type, der kan rumme mere end et materiale, der har forskellige flydeegenskaber. Ved indsatsstøbning skal formene fyldes på en måde, så indsatserne ikke glider ud af deres plads, da de vil bevare et stærkt greb; ellers vil støbeprocessen ikke være vellykket med hensyn til succes i overmold vs insert mold.

Æstetik og overfladefinish

Overmolding er typisk fokuseret på udseende og berøring. Designere bør overveje tekstur, farve og overfladens kvalitet. Når det gælder indsatsstøbning, følger æstetikken efter styrken, selv om der er sørget for en ordentlig efterbehandling for at sikre, at det endelige produkt lever op til kvalitetsstandarderne.

Krav til termisk ekspansion

Forskellige materialer har forskellig ekspansionshastighed. Både ved overstøbning og indsatsstøbning kan manglende hensyntagen til varmeudvidelse føre til revner, forkert justering eller lav vedhæftning. Det er vigtige punkter, der skal tages i betragtning, når man taler om indsatsstøbning kontra overstøbning.

Omkostninger og produktionstid

Moralen i historien, som kan læres for at producere på den bedst mulige måde, er forståelsen af omkostningerne og produktionstiden for processerne med overstøbning og indsatsstøbning. Begge metoder har deres problemer, som påvirker de samlede priser og hastigheden.

Indledende omkostninger til skimmelsvamp

Overstøbningen kan kræve mere komplekse forme for at kunne rumme de mange materialer. Det kan øge opstartsomkostningerne til værktøj. Denne investering kan dog betales med en reduktion af kravene i fremtiden under monteringen.

Omkostningerne til støbning af indsatser er også større end omkostningerne til formen, fordi der er brug for et fastspændingssystem til indsatserne. Formens design er vigtigt for at undgå fejl under produktionen. Når man sammenligner de to muligheder for indsatsformning og overformning, er den første investering i formen ofte den samme, men baseret på emnets kompleksitet.

Materiale- og arbejdsomkostninger

Overstøbning kan også spare arbejdsomkostninger, fordi det kan gøres, når dele kombineres i en enkelt proces. Det giver også mulighed for at bruge en mindre mængde bløde materialer som greb og belægninger, og det sparer ressourcer.

Støbning af indsatser. Indsatser kan udarbejdes, før de støbes. Men når det er automatiseret, sænker det omkostningerne til samling efter produktionen, hvilket kan reducere arbejdsomkostningerne på lang sigt. Dette er en af nøglefaktorerne i beslutningen om at lave/overstøbning og indsætte støbningen.

Produktionshastighed

I tilfælde af overstøbning kan materialet sprøjtes ind mere end én gang, hvilket resulterer i en længere cyklus, men det kan anvendes til at fjerne efterbehandling og samling.

Man kan opnå en hurtig støbning af indsatsen, når processen med at placere indsatsen er forenklet, især med automatiserede linjer. Det giver en fordel ved brug i store mængder, hvor effektivitet er altafgørende.

Omkostningseffektivitet

Den relevante proces kan give besparelser i det lange løb. Overstøbning reducerer den montering, der skal udføres, og det sparer omkostninger til arbejdskraft. Brugen af indsatsstøbning gør delene stærkere, og forekomsten af fejl er minimal. Ved at måle disse faktorer vil producenterne kunne beslutte, hvilken der skal bruges: overmold vs insert mold eller insert molding vs overmolding.

Almindelige fejl at undgå

Ved overstøbning og indsatsstøbning kan visse fejl gå ud over kvaliteten af et produkt og øge produktionsomkostningerne. Bevidsthed om disse fælder er en af måderne at sikre, at produktionen bliver en succes.

Valg af inkompatible materialer

Brugen af materialer, der ikke binder godt til hinanden, er en af de mest almindelige fejl, der begås ved overstøbning. I tilfælde af indsatsstøbning går revnerne eller delene i stykker, når de anvendte indsatser ikke er modstandsdygtige over for støbningstrykket. Når man beslutter sig for, om man vil bruge en indsatsform eller en overform, skal man altid tjekke materialekompatibiliteten.

Forkert justering af indsatser

Når der er tale om en indsatsstøbningsproces, kan den forkerte placering af indsatser føre til, at indsatserne flytter sig under indsprøjtningen, og det forårsager defekter eller svage områder. Fejlplacering reducerer den mekaniske styrke og øger afvisningsprocenten. Positionering er en meget vigtig parameter, når det drejer sig om at sammenligne processen med over måneder og insert mold-processer.

Ignorerer termisk udvidelse

Den procentvise vækst af forskellige materialer baseret på varme varierer. Hvis man ignorerer dette, kan det føre til vridning, revner eller adskillelse i de overstøbte og også i de indsatsstøbte dele. Bemærk: Termisk udvidelse: Når man går i gang med et design, skal det altid overvejes, især når det drejer sig om et projekt med indsatsstøbning vs. overstøbning.

Dårligt formdesign

Materialets flow kan være ujævnt, og delene kan ikke dækkes eller fjernes på grund af en dårligt tegnet form. Det kan påvirke æstetikken i tilfælde af overstøbning; det kan reducere den mekaniske styrke i tilfælde af indsatsstøbning. Der skal være det rigtige design af formen for at opnå maksimal overstøbning sammenlignet med indsatsstøbning.

Springe kvalitetstjek over

Fremstillingsprocessen kan være forhastet og ikke ordentligt kontrolleret, og fejlene vil blive overset. Kvalitetskontroller udføres regelmæssigt for at sikre, at alle dele er robuste, holdbare og udformet, så de passer til standarderne. Det er en af de vigtigste aktiviteter i forbindelse med effektiv overstøbning og indsatsstøbning.

Fremtidige tendenser

Fremstillingsindustrien er dynamisk. Både overmolding og insert molding tilpasser sig ny teknologi og nye materialer. Forudseelse af fremtidige tendenser hjælper virksomheden med at være konkurrencedygtig og innovativ.

Avancerede materialer

Der udvikles bedre polymerer og kompositter, som er stærkere, mere fleksible og mere hårdføre. Det er materialerne, der gør overmolding og insert molding stærkere, og derfor bliver produkterne lettere, stærkere og mere alsidige. Ny materialevidenskab kan bruges til at forbedre mulighederne for insert mould vs overmold.

Automatisering og robotteknologi

På grund af automatisering er produktionen af overstøbte og indsatsstøbte dele under udvikling. Med maksimal præcision kan robotter indsætte indsatserne og reducere antallet af fejl og forkorte produktionsprocessen. Tendensen gør produktionen inden for overmold vs insert mold mere effektiv og mindre arbejdskrævende.

Integration med 3D-printning

3D-print kombineres med overmolding og insert molding for at kunne lave hurtige prototyper og produktion i lille skala. Det giver designerne mulighed for at arbejde med komplekse former, reducere leveringstiden og skræddersyede dele, og det øger fleksibiliteten i hele systemet i tilfælde af indsatsstøbning i forhold til overstøbning.

Bæredygtig produktion

Bæredygtigheden af materialer og processer er nu udbredt inden for både overmolding og insert molding. I de nuværende produktionstendenser inden for overstøbning og indsatsstøbning bruger virksomhederne biologisk nedbrydelig plast og genanvendelige indsatser for at reducere miljøpåvirkningen.

Smart produktion

Internet of Things (IoT) og sensorer, der bruges til at designe støbeforme, giver mulighed for at overvåge temperatur, tryk og flow af materialer i realtid. Det gør det muligt at undgå fejl, optimere produktionen og kontrollere kvaliteten ved overstøbning og indsatsstøbning.

Konklusion

Valget af overstøbning og indsatsstøbning afhænger af hensigten med produktet. Overstøbning er den bedste løsning, hvis du har brug for blødhed, komfort eller skønhed. Indsatsstøbning vil være det bedste valg, når mekanisk styrke og holdbarhed er af betydning på det pågældende tidspunkt. Oplysningerne om forskellen mellem indsatsform og overform, overform og indsatsform, forskellen mellem overform og indsatsform og designkravene til indsatsform og overform kan hjælpe en producent med at træffe en sund beslutning.

Endelig er der problemet med overstøbning vs. indsatsstøbning, der ganske enkelt kan beskrives som processen med et perfekt match mellem processen og produktets krav. Med den rigtige tilgang spares der tid, omkostningerne reduceres, og der fremstilles funktionelle produkter af høj kvalitet, som lever op til industristandarderne.

Skriv en kommentar

Vil du deltage i diskussionen?Du er velkommen til at bidrage!