El acelerado mundo actual gira en torno a la innovación. Las empresas y los inventores deben estar en condiciones de transformar las ideas en productos concretos en poco tiempo. Aquí es donde entra en juego el servicio de prototipado rápido; mediante el prototipado rápido, el diseñador y los ingenieros pueden crear un modelo real de su idea antes de comprometerse plenamente con la producción. Ahorra tiempo, reduce costes y mejora la calidad de los productos.

Entre los elementos de este proceso, el uso de servicios de prototipado rápido es uno de ellos. Estos servicios facilitan la conversión de diseños web en productos reales. Estos servicios son necesarios para un emprendedor o una empresa. El prototipado rápido permite desarrollar prototipos que también pueden utilizarse para probar el diseño e identificar defectos y corregirlos en un tiempo mínimo.

¿Qué es la creación rápida de prototipos?

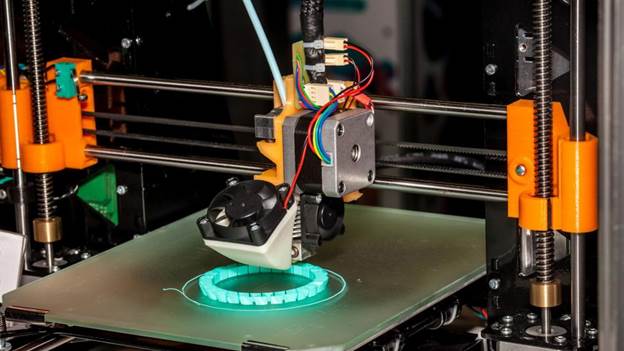

Creación rápida de prototipos es una tecnología que permite a los diseñadores desarrollar en poco tiempo un modelo físico de un diseño digital. Las ideas pueden convertirse en objetos reales mediante un servicio de prototipado rápido para ser probadas y perfeccionadas. Con los servicios de prototipado rápido, las empresas pueden hacerse una idea de cómo será y funcionará un producto incluso antes de su producción completa. La calidad y la precisión están garantizadas gracias a la aplicación de servicios profesionales de prototipado rápido y a la capacidad de producir piezas resistentes y de calidad mediante el uso de servicios de mecanizado de prototipado rápido. El servicio de prototipado rápido hace que la innovación sea rápida, segura y más rentable.

Definición de servicios de prototipado rápido

El prototipado rápido es la tecnología que se aplica para crear modelos 3D con ayuda de archivos de diseño asistido por ordenador (CAD) con gran rapidez. En el proceso de diseño se requiere un servicio de prototipado rápido. Ayuda a mejorar la innovación, el diseño de los productos y la reducción de los plazos de entrega.

Todos los servicios de prototipado rápido pueden ser de distintos tipos. Por ejemplo, utillaje y fijación, piezas de producción de bajo volumen, entre otros. La impresión tridimensional de prototipos a la cera perdida (LW) es una tecnología que puede utilizarse en la creación de prototipos.

Un ejemplo sería el prototipo de un nuevo equipo de defensa de una empresa de ingeniería, que puede ser un prototipo fabricado a través de un servicio denominado de prototipado rápido. Entregan al proveedor un archivo de especificaciones que es exhaustivo en forma de archivo CAD. FDM puede utilizarse para desarrollar un prototipo en sólo un par de horas o días. Esto es mucho más rápido que la producción tradicional, que puede llevar semanas.

Las empresas pueden recurrir a servicios profesionales de prototipado rápido para acceder a prototipos de alta calidad que pueden utilizarse en pruebas y visualización. Los servicios de mecanizado de prototipado rápido también pueden utilizarse en casos de precisión y resistencia. Se pueden encontrar aplicables en casos en los que los inventores, artistas, ingenieros y contratistas de la industria de defensa necesitan modelos que funcionen o ayudas visuales rápidas.

Proceso de creación rápida de prototipos

El prototipado rápido ayuda a convertir ideas en modelos reales y experimentables en muy poco tiempo. Para ser preciso y eficaz, un servicio de prototipado rápido debe seguir una serie de pasos.

Diseñar el modelo

La primera es la creación de un diseño digital con la ayuda de un software CAD. Con los servicios de prototipado rápido se crea un prototipo. El modelo que se desarrolle podrá proporcionar resultados precisos gracias al diseño adecuado.

Selección de materiales

Es importante elegir el material adecuado. El uso de los llamados servicios profesionales de prototipado rápido se basa en la selección de plásticos, metales, materiales compuestos o cerámica, en función de las necesidades del proyecto.

Construir el prototipo

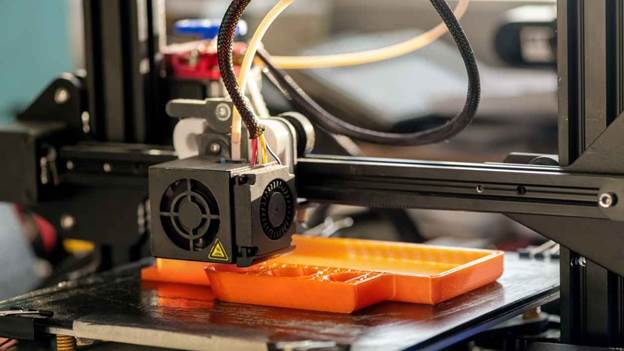

Con ayuda de los métodos pertinentes, se desarrolla el prototipo. El resto utiliza la impresión 3D, y algunos pueden fabricarse con la ayuda de los servicios de mecanizado de prototipado rápido, en los que las piezas son precisas o sólidas.

Pruebas y evaluación

Una vez construido, el prototipo se somete a pruebas de funcionalidad, ajuste y resistencia. Uno de los servicios es la creación rápida de prototipos, que ayudaría a realizar ajustes rápidos para mejorar el diseño.

Finalización y perfeccionamiento

Una vez probado, el prototipo se reduce a las especificaciones. La producción o presentación del modelo final debe prepararse con servicios profesionales de prototipado rápido.

Los llamados servicios de prototipado rápido permiten ahorrar tiempo, reducir costes y poner en práctica las ideas con el mínimo esfuerzo tras un proceso de este tipo.

Aplicación La innovación en el diseño refleja el progreso continuo de cualquier producto o servicio

En la innovación del diseño, el prototipado rápido desempeña un papel importante. Se trata del llamado servicio de prototipado rápido, que permite a los diseñadores crear los modelos en muy poco tiempo y probar las ideas novedosas en un plazo breve. Esto ayuda a reducir errores y a mejorar la calidad de los productos.

Probar nuevos conceptos

Los llamados servicios de prototipado rápido también permiten a los diseñadores transformar las ideas en modelos reales. Esto permite a los equipos ver, sentir y experimentar con las ideas hasta la plena producción.

Mejorar el diseño de los productos

Los servicios profesionales de prototipado rápido se aplican para perfeccionar el diseño en un terreno de pruebas y retroalimentación. Suponiendo pequeñas modificaciones, es posible aplicarlas en un plazo bastante breve para ahorrar tiempo y costes.

Acelerar el desarrollo

Los servicios de mecanizado rápido de prototipos también son más rápidos que los convencionales a la hora de fabricar piezas complejas e incluso prototipos funcionales. Esto facilita el proceso de innovación.

Exploración creativa: Soporte

Es un servicio que permitirá a inventores, ingenieros y artistas poner a prueba múltiples ideas mediante el desarrollo de un servicio de prototipado rápido. Esta flexibilidad fomenta la capacidad de producir nuevas soluciones y productos finales de alta calidad.

Gracias a los servicios de prototipado rápido, las empresas pueden ser más innovadoras, asumir menos riesgos y fabricar productos que respondan a las exigencias del mercado.

Tabla técnica de los distintos métodos de prototipado rápido

| Método de creación de prototipos | Tipo de material | Resolución de capa (mm) | Velocidad de construcción (cm³/h) | Coste típico por pieza ($) | Resistencia (% de producto final) |

| Modelado por deposición fundida (FDM) | ABS, PLA | 0.1 - 0.3 | 15 - 25 | 50 - 200 | 60 - 70 |

| Estereolitografía (SLA) | Resina fotopolímera | 0.025 - 0.1 | 8 - 15 | 80 - 300 | 50 - 65 |

| Sinterización selectiva por láser (SLS) | Nylon, PA12 | 0.05 - 0.15 | 10 - 20 | 100 - 400 | 80 - 90 |

| Modelado multichorro (MJM) | Resina | 0.016 - 0.03 | 5 - 10 | 150 - 500 | 55 - 70 |

| Fabricación de objetos laminados (LOM) | Papel, plástico, metal | 0.1 - 0.3 | 20 - 40 | 60 - 250 | 40 - 60 |

| Mecanizado CNC | Aluminio, acero inoxidable | 0.01 - 0.05 | 5 - 15 | 200 - 1000 | 90 - 100 |

Notas:

Resolución de capas: Espesor mínimo de un elemento que puede imprimirse o mecanizarse de forma fiable.

Velocidad de construcción: el volumen de material (aproximadamente) que se imprime por hora

Fuerza: porcentaje que está cerca de la parte del producto final.

Los clientes ideales de los servicios de prototipado rápido

La creación rápida de prototipos puede ser de ayuda para muchos profesionales. El servicio de prototipado rápido también puede ayudar a todo el mundo en situaciones en las que es necesario materializar las ideas en modelos reales y comprobables en un breve plazo de tiempo.

Inventores y empresarios

Los servicios de prototipado rápido son beneficiosos para las empresas de nueva creación y los inventores porque no necesitan incurrir en grandes costes de producción para crear dichos prototipos. Esto ayuda a experimentar y a atraer inversores.

Ingenieros y diseñadores

Servicios profesionales de prototipado rápido: Son los servicios que ayudan a los ingenieros y a los diseñadores de productos a desarrollar prototipos correctos y que funcionen. Esto ayuda a mejorar los diseños y a reducir los errores en la producción.

Profesionales y artistas imaginativos

Es posible con la ayuda del llamado servicio de prototipado rápido, que permite a los artistas u otras personas del mundo de la creación dar vida a sus ideas. Los prototipos proporcionan una representación visual que puede aplicarse en la planificación, las presentaciones o las exposiciones.

Contratistas en Industria y Defensa

Los servicios de mecanizado de los servicios de prototipado rápido son muy demandados por empresas industriales o militares para proporcionar componentes de alta calidad que sean duraderos, más precisos y funcionales. Esto aumenta el ritmo de desarrollo y pruebas.

Instituciones educativas

Los servicios de prototipado rápido se aplican en escuelas y universidades para enseñar a los estudiantes cómo se llevan a cabo los procesos de diseño, ingeniería y fabricación. Permite impartir enseñanza práctica con modelos reales.

Estos usuarios podrán ahorrar tiempo, dinero y mejorar la calidad general de sus proyectos incorporando un servicio de prototipado rápido.

Servicios profesionales de prototipado rápido

La calidad es un aspecto a tener en cuenta a la hora de seleccionar un proveedor de servicios. Un servicio profesional de prototipado rápido garantiza que su modelo sea impecable y eficaz. Estos servicios disponen de alta tecnología, como impresión 3D, mecanizado CNC y corte por láser. Los profesionales conocen mejor los materiales, las tolerancias y las complejidades del diseño. Incluso tendrá la certeza de que su producto será de la mayor calidad posible con la ayuda de los denominados servicios gratuitos de prototipado rápido que ofrecen los profesionales.

La aportación de los servicios de mecanizado rápido de prototipos

Otros diseños no son algo que pueda imprimirse simplemente en 3D. Con esto llegan los servicios de mecanizado de prototipado rápido, que pueden realizarse en metales, plásticos y materiales compuestos. Son capaces de proporcionar precisión, además de la excelencia que el prototipado tradicional podría no proporcionar. Con estos servicios, se puede garantizar que su prototipo será el producto real. La integración de los servicios de mecanizado de prototipado rápido con otros procesos de creación de prototipos que producen los resultados más óptimos no es infrecuente en la mayoría de las empresas.

¿Cuáles son los elementos esenciales en el procedimiento técnico fundamental del prototipado rápido?

Creación de un diseño digital

El primer paso en el proceso de prototipado rápido sería un elaborado diseño asistido por ordenador en un programa CAD. Se trata del plano prototipo de este diseño. A continuación, se utiliza un servicio de prototipado rápido para acceder al archivo, lo que permite avanzar por todo el proceso en la dirección correcta.

Elegir el material adecuado

La selección del material adecuado es esencial. Los servicios profesionales de prototipado rápido pueden hacer recomendaciones sobre el material en función de su resistencia, flexibilidad y durabilidad. La elección correcta garantizará que el comportamiento del prototipo se asemeje al del producto final.

Construir el prototipo

A continuación, el prototipo se desarrolla mediante servicios de prototipado rápido. Puede tratarse de impresión 3D, fundición o mecanizado, según el método que se aplique. Los más importantes son las piezas de alta precisión o metálicas, y los servicios de mecanizado rápido de prototipos.

Pruebas y evaluación

Una vez creado el prototipo, se realiza una prueba del mismo en términos de funcionalidad y precisión del diseño. Los ajustes y mejoras pueden realizarse en un breve periodo de tiempo a través de un servicio de prototipado rápido y pasar a la producción a escala real.

Finalización y perfeccionamiento

El prototipo se sigue mejorando en función de los resultados de las pruebas. Los servicios profesionales de prototipado rápido garantizan la introducción efectiva de los cambios introducidos y el desarrollo de un modelo estable diseñado para su uso en producción.

Tipos de servicios de prototipado rápido

Hay muchos tipos diferentes de enfoques de servicios de prototipado rápido. Ambos métodos pueden utilizarse en función de las necesidades, los materiales y el nivel de precisión. La aplicación del tipo adecuado acelera y hace más exitoso el desarrollo.

Modelado por deposición fundida (FDM)

FDM es uno de los servicios de prototipado rápido más populares. Se desarrolla sobre la estrategia aditiva de producir piezas en capas de tipo termoplástico. Además, es rápido, barato y se aplica tanto a diseños de detalle pequeño como medio.

Estereolitografía (SLA)

SLA funciona con el uso de un láser para solidificar resina líquida. El uso de SLA en la fabricación de prototipos finos es habitual en los servicios de prototipado rápido de SAW Professional. Genera superficies curvas y modelos precisos que se pueden poner en práctica y presentar.

Soldadura láser selectiva (SLS)

En el SLS, es mediante un láser como se funden los materiales en polvo. El método permite a los servicios de mecanizado de prototipado rápido producir piezas duraderas y funcionales. El SLS puede utilizarse tanto para probar las propiedades mecánicas como la funcionalidad de pequeños lotes.

Modelado multichorro (MJM)

Se crea un prototipo recubriendo materiales creados por MJM. Puede capturar la geometría correcta y producir geometrías ricas. La MJM se aplica principalmente a modelos visuales y diseños complejos mediante un servicio de prototipado rápido.

Fabricación de objetos laminados a la cera perdida (LOM)

LOM es un proceso de construcción de prototipos mediante una serie de capas de materiales. Los servicios de prototipos rápidos LOM son adecuados para piezas grandes y diseños estructurales complejos. Es rentable en lo que respecta a la validación temprana de la estructura.

Existen varios tipos de servicios de prototipado rápido que resultan ventajosos. Con la ayuda de profesionales, es posible elegir la forma más adecuada de ahorrar tiempo y crear prototipos de alta calidad.

Ventajas de los prototipos rápidos

El tiempo es una cuestión extremadamente crucial en el desarrollo de productos. Los servicios de prototipos rápidos son modelos que se desarrollan con rapidez. Ahora es posible probar, cambiar y mejorar los diseños en cuestión de días, en lugar de meses antes. Esto limita el desarrollo global del producto. Además, un prototipo ayudará a vender una idea a inversores, clientes o miembros del equipo. Pueden ver, tocar e incluso comprender su idea en su totalidad.

El otro punto fuerte es la economía. Tener un modelo de producción completo puede resultar caro. El prototipado garantiza que los errores se detecten a tiempo. Las empresas se ahorran los costes de las costosas revisiones posteriores. Una de las formas inteligentes de innovar es recurrir a los servicios de prototipado rápido, que es una herramienta rentable.

La importancia de los servicios profesionales

No todos los prototipos son iguales. Ofrecen servicios de creación rápida de prototipos utilizando servicios profesionales de creación rápida de prototipos precisos y de alta calidad. Los profesionales se aseguran de que el tamaño, la selección de materiales y las pruebas sean los adecuados. Su experiencia es especialmente importante en el caso de proyectos complejos o productos con especificaciones muy restrictivas. Con ellos, la transición del prototipo a la producción se realiza sin problemas.

El funcionamiento de los servicios de mecanizado rápido de prototipos

Técnica científica: cómo diseñar un nuevo componente mecánico. Se puede tener un modelo 3D generado por ordenador. Pero para ejercer vida, se necesita una pieza. Aquí es donde entran en juego los servicios de mecanizado rápido de prototipos. El mecanizado permite fabricar piezas metálicas y de plástico de alta resistencia en poco tiempo. Se puede experimentar con el movimiento, la resistencia y el montaje antes de la producción en serie. Lo mejor es integrar los servicios de mecanizado rápido de prototipos con otros métodos.

¿Cuáles son las principales capacidades que una persona debe tener en cuenta a la hora de seleccionar un proveedor de servicios de prototipado rápido?

Uno de los principales factores del éxito de la creación de prototipos es el proveedor pertinente. No todos los proveedores de servicio de prototipado rápido son igual de buenos, rápidos o hábiles. Las capacidades más significativas a tener en cuenta son las siguientes:

Conocimientos y experiencia

Se espera que ofrezca años de experiencia en el ámbito de los servicios profesionales de prototipado rápido. En el diseño, los expertos conocen los materiales, las tolerancias y las complejidades para que los prototipos funcionen correctamente.

Tecnología y equipos

La nueva tecnología utilizada en la introducción de servicios de prototipado rápido en la actualidad son las impresoras 3D, las máquinas CNC y las cortadoras láser. Servicios de mecanizado de prototipado rápido también son significativos, de tal manera que ha habido algún tipo de precisión, y también para gestionar las piezas complejas o de metal.

Selección de materiales

Es importante trabajar con un gran número de materiales. El servicio de prototipado rápido adecuado puede ayudarle a elegir entre plásticos, metales o materiales compuestos en función de los requisitos de su proyecto.

Rapidez y plazos

La rapidez del proveedor es lo más importante, ya que la creación rápida de prototipos permite ahorrar tiempo. Los servicios de prototipado rápido serán lo suficientemente eficientes y reducirán los ciclos de desarrollo del producto, además de permitir que sus ideas sean comercializables más rápidamente.

Calidad y precisión

La precisión es necesaria en los prototipos que se van a probar o utilizar para planificar la producción. Los servicios profesionales de prototipado rápido garantizan que sus modelos sean de alta calidad y que se encarguen siempre.

Apoyo y consulta

Un gran proveedor proporciona orientación durante el mismo. El uso de los servicios de mecanizado rápido de prototipos con la ayuda de profesionales garantiza la optimización de los diseños y la exclusión de posibles problemas.

Una mesa de prototipado rápido de materiales

| Material | Tipo | Resistencia a la tracción (MPa) | Resistencia a la flexión (MPa) | Densidad (g/cm³) | Uso típico |

| ABS | Termoplástico | 40 - 50 | 65 - 75 | 1.04 | Prototipos FDM, piezas funcionales |

| PLA | Termoplástico | 50 - 70 | 70 - 90 | 1.24 | Prototipos FDM, modelos visuales |

| Resina fotopolímera | Termoestable | 45 - 65 | 80 - 100 | 1.1 - 1.2 | SLA/MJM, modelos detallados |

| Nylon (PA12) | Termoplástico | 48 - 70 | 60 - 90 | 1.01 | Piezas funcionales SLS, prototipos duraderos |

| Aluminio 6061 | Metal | 290 | 310 | 2.70 | Mecanizado CNC, prototipos funcionales |

| Acero inoxidable 316 | Metal | 520 | 550 | 8.0 | Mecanizado CNC, piezas de alta resistencia |

| Compuesto (fibra de carbono + nailon) | Compuesto | 100 - 120 | 120 - 140 | 1.3 - 1.5 | Prototipos de alta resistencia, pruebas funcionales |

| Cerámica | Cerámica | 150 - 300 | 200 - 400 | 2.0 - 3.5 | Prototipos resistentes al calor, electrónica |

Notas:

Resistencia a la tracción: la tensión máxima que puede soportar un material.

Resistencia a la flexión: la tensión máxima antes de una curva o pliegue.

Densidad: Masa/volumen de la unidad de volumen, que es importante en el cálculo del peso.

El futuro del prototipado rápido

La tecnología evoluciona rápidamente. Además, la servicio de prototipado rápidoás material y más rápido de fabricar que nunca. Las innovaciones en impresión 3D y mecanizado CNC están dando lugar a prototipos cada vez más similares a los productos finales. Las empresas también pueden explorar, reintentar e innovar más que nunca.

Mantendrá la competitividad de su producto si subcontrata los llamados servicios profesionales de prototipado rápido. Cuanto más rápido fabrique un prototipo, más rápido podrá probarlo y mejorarlo. El plazo de comercialización también es más corto, y la satisfacción del cliente es menor.

Materiales de prototipado rápido

El servicio de prototipado rápido es muy sensible a la selección del material. Afecta a la robustez, resistencia y precisión del prototipo. Los distintos servicios denominados de prototipado rápido dependen del tipo de proyecto y del tipo de prueba, en función de sus propios materiales.

Plásticos

Los plásticos son los más utilizados. Es habitual encontrar ABS, PLA o resina como parte de FDM o SLA. Los servicios profesionales de prototipado rápido deciden la elección de los plásticos utilizados en modelos ligeros, rentables e intrincados.

Metales

El servicio de mecanizado rápido de prototipos se realiza con metales como el aluminio, el acero inoxidable o el titanio, en el caso de prototipos eficaces y resistentes. Se trata de los materiales más finos que pueden utilizarse en pruebas mecánicas y componentes potentes.

Compuestos

Los compuestos son una combinación de distintos materiales que ofrecen resistencia y flexibilidad. Se han fabricado prototipos con materiales compuestos resistentes a la tensión y el desgaste, y también precisos mediante un servicio de prototipado rápido.

Cerámica

Otros prototipos necesitaban acabados termodeslizantes o especiales. Los servicios de prototipado rápido son capaces de producir modelos de materiales cerámicos en modelos basados en la electrónica, la industria aeroespacial o industrias especiales.

La elección del material adecuado puede garantizar que un prototipo entregado con la ayuda de un servicio de prototipado rápido sea preciso, funcione y pueda probarse o demostrarse.

Elegir el proveedor de servicios adecuado

Hay que contar con el servicio de prototipado rápido adecuado. Tenga en cuenta la experiencia, la tecnología, el material y el plazo de entrega. El proveedor local proporcionará asesoramiento sobre diseño, materiales y procesos. Se requiere colaboración y comunicación para utilizar adecuadamente los servicios de prototipado rápido. Los profesionales ayudan a perfeccionar el diseño y a evitar los errores más comunes.

Servicios de prototipado rápido Aplicaciones

Los servicios de este tipo no pertenecen a una sola industria. Se utilizan en electrónica de consumo, automoción, aeroespacial, equipos médicos, etc. Los servicios de prototipado rápido también permiten a los ingenieros probar nuevos diseños en un lugar seguro. Se utilizan sobre todo en industrias de alta precisión, especialmente en el mecanizado rápido de prototipos. Los profesionales proporcionan una idea de los materiales y los procesos de fabricación y garantizan que los prototipos funcionen.

Sincere Tech: Su socio de confianza en prototipado rápido

Sincere Tech es un desarrollador progresivo de las denominadas soluciones de servicios de prototipado rápido con los principios de convertir la idea en realidad. En Sincere Tech, ofrecemos servicios de prototipado rápido y de bajo coste, y estos servicios se ajustan a los requisitos de inventores, ingenieros y empresas. Además, nuestros servicios de prototipado rápido son profesionales, precisos, eficaces y duraderos en todos sus proyectos. Al estar equipados con tecnologías modernas y ser competentes en el ámbito de los servicios de mecanizado de prototipado rápido, ayudamos a nuestros clientes a reducir gastos, ahorrar tiempo y acelerar el proceso de innovación. Trabajar con Sincere Tech significa tratar con un equipo bien organizado, cuyo mandato es desarrollar prototipos adecuados, funcionales e inventivos para cada industria.

Conclusión

A servicio de prototipado rápido se utiliza para transformar una idea en realidad. Las empresas pueden desarrollar, probar y perfeccionar sus productos con mayor eficacia y en menos tiempo gracias a los servicios de prototipado rápido. Con la ayuda de los servicios de mecanizado rápido de prototipos, se controlan la precisión y la resistencia, así como la calidad y la exactitud.

Ya no es una opción invertir en estos servicios en un mercado competitivo. Es necesario debido a la innovación, el ahorro de costes y la reducción del tiempo de comercialización. Sea rápido en reaccionar, adopte un servicio de prototipado rápido, colabore con especialistas y ponga en marcha sus conceptos.