El impacto de las piezas de bicicleta mecanizadas por CNC en los componentes ciclistas de alta calidad

Los avances en la tecnología de fabricación han sido los responsables de que estas piezas mecanizadas CNC hayan revolucionado la industria de la bicicleta. Es una parte importante de la creación de componentes de alta calidad, precisos y duraderos. La ventaja de este proceso de producción automatizado es la precisión, la consistencia y la eficacia en la producción. El mecanizado CNC se utiliza para fabricar componentes ligeros pero sólidos para la bicicleta que, en última instancia, mejoran el rendimiento general de la bicicleta y la experiencia del ciclista. Los cuadros de bielas y horquillas han pasado a utilizar el mecanizado CNC para construirlos, lo que ha cambiado por completo la forma de fabricar piezas para bicicletas. Las piezas mecanizadas CNC para bicicletas representan una excelente durabilidad con un atractivo diseño ligero gracias a que dichas piezas se fabrican con materiales de alta resistencia como aleaciones de aluminio, titanio, compuestos de carbono, etc. El mecanizado CNC ahorra problemas de puntos débiles, y el ajuste adecuado, y es ideal para ciclistas profesionales y aficionados.

El mecanizado CNC es una de las ventajas más destacadas del proceso para producir piezas en serie manteniendo constante su calidad. Su eficacia es especialmente útil para la industria de la bicicleta, cuyas dimensiones de componentes varían incluso un poco afectando mucho al rendimiento. Además, el mecanizado CNC permite la personalización, lo que a su vez permite a los ciclistas adaptar sus bicicletas a su estilo de conducción, terreno y gustos estéticos. Como líder mundial en la fabricación de conjuntos de componentes CNC para bicicletas, China ha proporcionado la capacidad de suministrar componentes a bajo coste y con buena calidad. Lo ha conseguido gracias a sus avanzadas y estrictas medidas de control de calidad, que han encumbrado al país como una opción para los fabricantes.

En este artículo, exploramos cómo la maquinaria CNC ha afectado a la industria de la bicicleta y, a continuación, presentamos las piezas de bicicleta mecanizadas CNC más duraderas, las herramientas que utilizan y qué es el fresado CNC. El mecanizado CNC seguirá siendo una parte orgánica de la evolución de la industria, ya que veremos más bicicletas más ligeras, resistentes y eficientes que nunca.

Piezas de bicicleta mecanizadas por CNC

El CNC (Control Numérico por Ordenador) es un sofisticado procedimiento de fabricación mediante el cual los materiales metálicos y compuestos se cortan, moldean y afinan con el uso de herramientas automatizadas. Esta técnica es útil para que los fabricantes fabriquen componentes de bicicleta complejos con gran precisión y consistencia.

Algunas de las piezas de bicicleta mecanizadas por CNC que se producen con más frecuencia son:

- Bielas - Esenciales para un pedaleo y una transferencia de potencia eficientes.

- Para mantener la suavidad al cambiar de marcha, puede ser necesario utilizar ganchos de cambio.

- Potencia del manillar - Ayuda para la estabilidad y la orientación.

- Pinzas de freno - Garantiza una potencia de frenado fiable.

- Los pedales mejoran el control y el agarre del ciclista.

El mecanizado CNC crea estos componentes con conjuntos de características muy similares de durabilidad, diseño ligero y excelente rendimiento.

Estos son los componentes de bicicleta mecanizados CNC más duraderos.

Los componentes de las bicicletas son muy duraderos y están diseñados con precisión, por lo que su fabricación mediante mecanizado CNC es importante. Los materiales resistentes y los procedimientos de mecanizado precisos garantizan que los participantes puedan utilizar las piezas de la bicicleta durante todo el día sin que ello afecte a su rendimiento y durabilidad. A continuación puede ver los componentes de bicicleta mecanizados mediante CNC más duraderos.

Marcos

El cuadro es uno de los componentes de la bicicleta mecanizados por CNC más duraderos. En términos de resistencia y ligereza, se suelen utilizar aleaciones de alta resistencia como el titanio (Ti-6Al-4V) y el aluminio (6061-T6).

- Un armazón de titanio ofrece una resistencia a la tracción de hasta 900 MPa, lo que supone una importante resistencia a la fatiga y la tensión.

- Los cuadros están fabricados en aluminio para ofrecer un equilibrio perfecto entre dureza y ligereza, mejorando así la manejabilidad sin aumentar innecesariamente el peso.

- El uso del mecanizado CNC proporciona una tolerancia precisa que disminuye las zonas débiles y aumenta la integridad estructural.

Los cuadros mecanizados mediante CNC ayudan a mantener un grosor uniforme de las paredes, lo que, sumado a una conducción suave y cómoda, se ve favorecido por cuadros capaces de soportar una gran fuerza de impacto.

Horquillas

Al ser los únicos eslabones de la moto que entran en contacto con el suelo, donde existe fricción entre el neumático y el suelo, las horquillas mecanizadas CNC son clave para la estabilidad y seguridad de la moto y están construidas para soportar cargas extremas.

- Horquillas: El acero al cromo molibdeno 4130 ofrece un material muy resistente y está orientado al ciclismo de alto rendimiento.

- Una horquilla de titanio es ligera y muy resistente a la fatiga, por lo que dura mucho tiempo.

- En el movimiento de mecanizado CNC, se eliminan los puntos de tensión, lo que permite una alineación precisa y una mayor estabilidad de marcha.

El estrés y los impactos a los que se someten las horquillas de ciclismo son continuos, por lo que el mecanizado CNC garantizará tolerancias ajustadas para la horquilla y mejorará la resistencia y durabilidad de toda la horquilla.

Manillar

El control del piloto es fundamental en los manillares, y el mecanizado CNC permite obtener manillares perfectos, resistentes y ergonómicos en función de la aplicación.

- Las aleaciones de aluminio más utilizadas, como la 7075-T6, son muy resistentes y ligeras.

- Los manillares de compuesto de carbono ofrecen una elevada relación resistencia-peso, por lo que son perfectos para los ciclistas orientados al rendimiento.

- Con el mecanizado CNC, se garantiza una alta precisión y se eliminan los puntos débiles conseguidos con la fundición y, en general, se consigue una barra que absorbe mejor los impactos.

Los manillares mecanizados mediante CNC se caracterizan por la eliminación de las zonas de concentración de tensiones que debilitan los manillares originales, haciéndolos estructuralmente estables durante el impacto y reduciendo el riesgo de lesiones o incomodidades para el piloto.

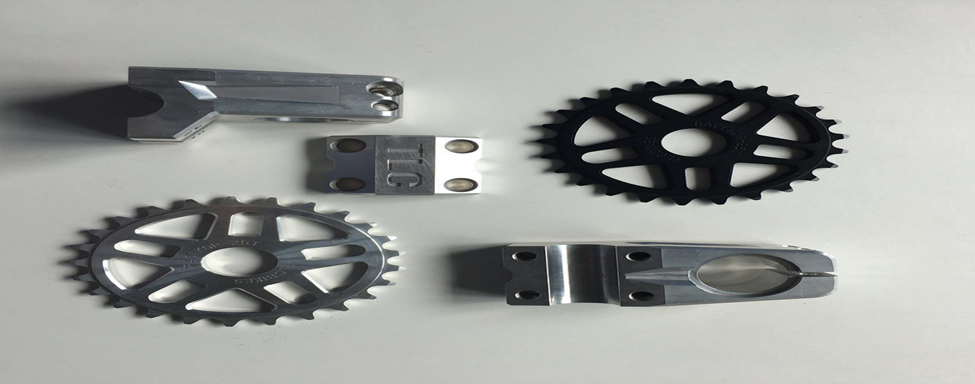

Bielas

Los platos y bielas son componentes sometidos a grandes esfuerzos por el pedaleo. Ayudan a fortalecer y endurecer una capacidad de mecanizado CNC.

- Los platos y bielas de aluminio 7075 de alta resistencia y bajo peso transferirán eficazmente tu potencia.

- Los platos y bielas de titanio son excepcionales a largo plazo, ya que son conocidos por su gran resistencia a la fatiga.

- Un modelo mecanizado mediante CNC tiene una mayor precisión dimensional y un buen acabado superficial, lo que reduce la fricción y, por tanto, mejora el rendimiento.

Dado que el mecanizado CNC es un proceso fiable, minimiza los puntos de fallo Los platos y bielas son ligeros pero muy duraderos, lo que les permite realizar ciclos de forma eficiente.

Bujes

El buje desempeña un papel esencial en el movimiento de la rueda y debe soportar fuerzas de rotación y cargas de peso constantes.

- Los bujes de aluminio 6061T6 se utilizan mucho por su gran resistencia y su composición ligera.

- Los rodamientos están perfectamente alineados mediante mecanizado CNC, lo que da como resultado una eficiencia óptima de la rotación.

- Con la tensión distribuida uniformemente, ayuda a la durabilidad general del cubo.

Los cubos se mecanizan según especificaciones exactas con mecanizado CNC para que no se salten ni un latido con el paso del tiempo.

Pinzas de freno

Las encargadas de presionar las pastillas de freno para proporcionar una potencia de frenado suficiente son las pinzas de freno. Sus pinzas son pinzas mecanizadas mediante CNC diseñadas para ser lo suficientemente ligeras, fuertes y resistentes al calor para rendir como se espera de ellas y ejemplificar un rendimiento de frenado constante. Estos materiales son excelentes en la disipación de calor y tienen una alta resistencia a la corrosión, de ahí que se utilicen comúnmente, como el aluminio de grado aeronáutico.

En resumen

Resulta que el mecanizado CNC se ha convertido en el método de más rápido crecimiento para producir piezas de bicicleta duraderas y de alto rendimiento. El mecanizado CNC me recompensó con la combinación perfecta de "precisión, resistencia y longevidad", desde cuadros y horquillas hasta bielas y bujes.

- Los cuadros de titanio y aluminio aportan ligereza y resistencia.

- Sus horquillas de acero Chromoly y titanio son resistentes a la fatiga.

- Ofrecen control y amortiguación, ya que están fabricados con manillares de aluminio y fibra de carbono.

- Hay bielas y bujes mecanizados mediante CNC para una mayor eficiencia y fiabilidad.

Las piezas de bicicleta mecanizadas mediante CNC ofrecen a los ciclistas ventajas como calidad duradera y alto rendimiento, así como durabilidad.

Pieza mecanizada CNC para bicicleta Materiales clave

Aleaciones de aluminio

Entre los aluminio aleaciones utilizadas para el mecanizado CNC de piezas de bicicleta, la 6061-T6 es la más común. Estas aleaciones permiten obtener componentes ligeros pero con una buena resistencia, lo que las hace perfectas para bicicletas de alto rendimiento.

Las aleaciones de aluminio también tienen una alta elasticidad a la tracción de hasta 310 MPa. Las tolerancias ajustadas y la menor rugosidad superficial se consiguen en los componentes gracias al mecanizado CNC. Por su dureza y resistencia a la corrosión, las aleaciones de aluminio se utilizan habitualmente para bielas, manillares y potencias.

El aluminio también es altamente mecanizable y, por tanto, la producción puede realizarse con mayor rapidez. Por ello, las piezas de bicicleta mecanizadas por CNC ofrecen las mejores prestaciones con el menor peso posible.

Calidades de titanio

Las aleaciones de titanio como Ti-6Al-4V se utilizan para fabricar muchos componentes de alta gama para bicicletas. Esta aleación es excepcional por su gran solidez y resistencia a la fatiga (con una resistencia a la tracción de 900 MPa).

El titanio tiene una baja densidad y, por tanto, hace que las potencias, las tijas de sillín e incluso los tornillos sean duraderos y cómodos de montar. Debido a la precisión de las piezas de mecanizado CNC de fresado de bicicletas, que cuentan con tolerancias estrechas, que son ideales para piezas de alto rendimiento.

Otra de las principales ventajas del titanio es que no se corroe fácilmente y puede soportar condiciones climáticas adversas. Además, el titanio es biocompatible, por lo que es una gran opción para las personas con piel sensible o casos de alergia.

Tipos de acero

Las piezas de bicicleta mecanizadas por CNC son muy utilizadas en acero, especialmente, aleaciones de alta resistencia como el cromoly 4130. El acero tiene una excelente absorción de impactos y las costillas se hacen con una resistencia a la tracción de alrededor de 850 MPa para hacer el material muy duradero.

Los cuadros, horquillas y accesorios menores están fabricados con piezas de acero mecanizadas por CNC, que son estructuralmente fuertes y duraderas. Con la ayuda del mecanizado CNC, estos componentes pueden fabricarse con dimensiones precisas para que encajen perfectamente en las bicicletas.

El acero es económico, por lo que se emplea en la mayoría de bicicletas económicas y de gama alta. La propiedad de alto módulo de elasticidad permite absorber las vibraciones y aumentar así la comodidad del ciclista en terrenos accidentados.

Compuestos de carbono

En el mecanizado CNC de componentes para sofisticadas piezas de bicicleta, en una gran variedad de aplicaciones, se utilizan muy a menudo compuestos reforzados con fibra de carbono, debido a su elevada relación resistencia-peso. Suelen emplearse en cuadros, horquillas y juegos de ruedas en los que se buscan estructuras ligeras pero muy rígidas.

Con una resistencia a la tracción, según el tipo, de hasta 3000 MPa. Los compuestos de carbono pueden suministrarse con precisión de mecanizado CNC y durabilidad, ofreciendo un producto ciclista competitivo.

Las propiedades amortiguadoras de la fibra de carbono son una de sus mayores ventajas: mejoran el confort de marcha, absorbiendo las vibraciones. Además, los compuestos de carbono son extremadamente resistentes a los factores medioambientales, por lo que pueden funcionar a largo plazo en diversas condiciones.

Plásticos

Los plásticos tienen un papel en el mecanizado CNC en la industria de la bicicleta. El nailon, el policarbonato y el PVC son los materiales más utilizados por su ligereza y resistencia a los impactos, así como por su durabilidad.

- El nailon es famoso por ser muy resistente, flexible y adecuado para piezas sometidas a esfuerzos repetidos.

- La resistencia al impacto del policarbonato es muy alta, por lo que puede utilizarse en piezas expuestas a grandes fuerzas, vibraciones elevadas, etc.

- El PVC destaca por su rentabilidad y su resistencia al desgaste, por lo que se considera una solución viable para fabricar componentes no portantes.

La elección del material plástico viene determinada por las necesidades particulares del componente de la bicicleta y por la aplicación para la que está diseñado. Las piezas de plástico fabricadas mediante mecanizado CNC son duraderas, pero garantizan un bajo peso total de la bicicleta para que sea lo más precisa y fiable posible.

Beneficios materiales

Es de vital importancia elegir el material adecuado para las piezas de bicicleta mecanizadas por CNC.

- Por otro lado, el aluminio es ligero y resistente a la corrosión.

- El titanio es inigualable por su resistencia y durabilidad, de ahí que sea ideal para bicicletas de alto rendimiento.

- Es barato y resistente, con una excelente absorción de impactos.

- Los compuestos de fibra de carbono, que se utilizan sobre todo para aumentar la velocidad y el confort, ofrecen la mejor relación de resistencia.

- Todos estos materiales se aplican al mecanizado CNC con la certeza de una gran precisión, repetibilidad y durabilidad.

- La elección del material aumenta aún más el rendimiento, la longevidad y la eficacia de los componentes de la bicicleta.

El proceso de mecanizado CNC de piezas de bicicleta

La industria de la bicicleta es una de las aplicaciones típicas del mecanizado CNC, ya que éste es capaz de fabricar piezas precisas, complejas y duraderas. El proceso es eficiente, preciso y consistente, lo que lo convierte en el proceso perfecto para la fabricación de piezas de bicicleta de alto rendimiento. A continuación se ilustra paso a paso el uso del mecanizado CNC para fabricar piezas de bicicleta.

1. Diseño

El primer paso del mecanizado CNC es un diseño digital creado mediante software de diseño asistido por ordenador (CAD). Se trata de un plano digital que incluye propiedades como las dimensiones, la geometría y otros detalles de una pieza de bicicleta fabricada en una fresadora de tres ejes con control numérico por ordenador (CNC). Diseñar bien garantiza que el resultado final de la solución del producto cumplirá los requisitos de ingeniería y rendimiento.

2. Programación

Una vez finalizado el diseño, se elabora un programa informático con software de fabricación asistida por ordenador (CAM). Después, este programa transforma el diseño en órdenes legibles por la máquina, es decir, la trayectoria de la herramienta, la profundidad de corte y la secuencia de corte. Tras la programación, las instrucciones se cargan en la máquina CNC y permiten automatizar el proceso de mecanizado.

3. Selección y preparación del material

A continuación, hay que seleccionar el material adecuado para una determinada pieza de bicicleta que tenga ciertas propiedades como resistencia, peso y resistencia a la corrosión. Los materiales más comunes son las aleaciones de aluminio, el titanio, la fibra compuesta de carburo y el acero de alta resistencia. El material seleccionado se corta y se prepara para que quepa en el espacio de la máquina CNC.

4. Mecanizado

Con la adición de herramientas de corte como brocas, fresas y tornos, la máquina CNC está lista para utilizarse en torneado, taladrado, mandrinado y corte. La herramienta de corte controlada por ordenador empieza a tomar forma en bruto en el material después de haber eliminado el material sobrante para fabricar el componente deseado. El mecanizado CNC ofrece alta precisión, acabado suave y tolerancia exacta, por lo que cada pieza es consistente y fiable.

5. Acabado

Tras el mecanizado, el acabado de la pieza de bicicleta puede ser necesario para mejorar su valor estético, durabilidad y rendimiento. Esto puede incluir:

- Se aplica un pulido suave y refinado para mejorar el aspecto.

- Lijar las asperezas y otras imperfecciones.

- Y otros anodizados o revestimientos con fines de corrosión y longevidad.

6. Inspección y control de calidad

El último paso es una rigurosa inspección que conduce al fallo de la pieza para que cumpla los requisitos de tolerancia, resistencia y precisión dimensional. Se verifica mediante herramientas sofisticadas como una máquina de medición de coordenadas (MMC) o un escáner láser para comprobar la precisión y la coherencia. Cualquier desviación se ajusta en el programa CNC para futuras mejoras de la producción.

El papel del fresado de piezas de bicicleta Mecanizado CNC en la fabricación

Las piezas de mecanizado CNC de fresado de bicicletas se fabrican mediante un proceso de fresado especializado en deshacerse de materiales a partir de un bloque sólido que produce formas exactas y diseños complicados. El fresado CNC tiene una ventaja sobre los procesos de fabricación convencionales debido a su alto control sobre el producto final que conduce a un alto nivel de detalle y personalización en las piezas de bicicleta.

Ventajas del fresado CNC en la producción de piezas de bicicleta

Precisión y exactitud

Las fresadoras CNC garantizan que cada pieza encaje a la perfección, ya que funcionan con tolerancias extremadamente estrechas. Es especialmente importante en el negocio de las bicicletas, donde el rendimiento depende incluso de pequeños cambios.

Durabilidad y resistencia

Metales de alta calidad como el aluminio, el titanio y los compuestos de fibra de carbono, entre otros, son algunos de los metales con los que se fabrican las piezas mecanizadas por CNC. Estos materiales se han aplicado para mejorar la resistencia y la longevidad de los componentes de la bicicleta.

Personalización

Los ciclistas y los fabricantes pueden fabricar piezas personalizadas para necesidades ciclistas concretas. Los diseños pueden ser únicos, se puede mejorar la aerodinámica y reducir el peso.

Coherencia y producción en serie

Una diferencia es que, a diferencia del mecanizado manual, el fresado CNC proporciona consistencia en grandes lotes de fabricación, lo que resulta ideal para la producción en serie con alta calidad.

Diferencia entre bicicleta y bicicleta y sus partes

Muchas veces los términos bicicleta y moto se utilizan indistintamente, pero ambos tienen un significado diferente en sus respectivos contextos.

1. Bicicleta

Una bicicleta es un vehículo de dos ruedas que se impulsa pedaleando. No tiene motor y todo se hace con esfuerzo humano. Las bicicletas se utilizan para varios fines, como desplazarse al trabajo, hacer ejercicio y practicar deportes (como las carreras de carretera o la bicicleta de montaña).

2. Bicicleta

Esta palabra es un término más general que puede englobar la palabra bicicleta (que se pedalea) y la palabra moto (motocicleta con motor). Es cierto que cuando la gente habla de "bicicleta", puede referirse a una bicicleta normal o a una moto, eso si el contexto lo avala.

3. Partes de una bicicleta frente a una motocicleta (Bike)

| Sección | Bicicletas de tracción humana | Motocicleta Bicicleta |

| Marco | Metal ligero de fibra de carbono | Acero más pesado Aluminio |

| Ruedas | Fino o grueso, según el tipo | Más ancho y duradero |

| Pedales | Sirve para hacer avanzar la bicicleta | Ausencia en motocicletas |

| Cupón y embrague | Interconecta los pedales a las ruedas | Utilizar una cadena o un eje de transmisión |

| Frenos | Frenos de llanta o de disco | Frenos de disco o de tambor |

| Dirección | Recto o curvo | Acelerador, embrague, maneta y otros mandos |

| Asiento | Estrecho y ligero | Más ancho y suave |

| Motor | Ningún motor depende de la fuerza humana | Tiene un motor de combustible |

| Sistema de combustible | No es necesario | Requiere gasolina o energía eléctrica |

| Luces | Reflectores o pilas básicas | Faros, intermitentes y luces de freno |

Una forma fácil de resumirlo es que todas las bicicletas son bicicletas, pero no todas las bicicletas son bicicletas. La mayor diferencia es que las bicicletas se impulsan con los pedales del ciclista, mientras que los biciclos lo hacen con un motor.

Por qué las piezas de bicicleta mecanizadas por CNC son el futuro del ciclismo

El aumento de la demanda de bicicletas de alto rendimiento ha impulsado a los fabricantes a utilizar piezas de bicicleta mecanizadas por CNC a medida que avanza la tecnología ciclista. Las ventajas del mecanizado CNC en el diseño de bicicletas se traducen en innovaciones en el diseño, la reducción del peso y la optimización de los materiales, lo que se traduce en bicicletas más rápidas, resistentes y eficientes.

Las principales ventajas de las piezas de bicicleta mecanizadas por CNC son:

- Estas piezas mecanizadas mediante CNC contribuyen a que las bicicletas sean más aerodinámicas y eficientes.

- Diseño ligero: Garantizar la fuerza sin peso innecesario, mecanizado de precisión disminuye el peso extra.

- Las piezas CNC ofrecen un mejor atractivo estético, ya que tienen acabados suaves y detalles intrincados en comparación con las piezas conformadas previamente.

- Fiable: el mecanizado CNC no tiene defectos y es muy duradero.

- Estas ventajas hacen que los componentes mecanizados CNC sean los preferidos por muchos ciclistas profesionales y la mayoría de los fabricantes de bicicletas, por lo que es un estándar común de los componentes de bicicletas de gama alta.

La fabricación mundial de piezas de bicicleta de China en el mecanizado CNC

China es una fuerza poderosa en el mecanizado CNC de los proveedores de bicicletas. Debido a la disponibilidad de instalaciones de fabricación avanzadas, mano de obra cualificada y conocimientos tecnológicos, el país es un destino aceptado para la producción de piezas de bicicleta de mecanizado CNC.

¿Cuáles son las razones para elegir China CNC mecanizado de piezas de bicicleta

1. Producción rentable

El precio competitivo más la opción de calidad que ofrece China la convierten en una buena elección tanto para la producción a pequeña como a gran escala de piezas mecanizadas CNC para bicicletas.

2. Alta precisión y control de calidad

Los componentes producidos por los fabricantes chinos son precisos y duraderos y siguen las normas internacionales, ya que los fabricantes chinos utilizan máquinas CNC de última generación para fabricar los productos.

3. Capacidad de producción en serie

China está equipada con instalaciones de producción a gran escala para dar cabida a pedidos al por mayor y es capaz de entregar bicicletas a tiempo, ya que atiende bien a las marcas mundiales de bicicletas.

4. Tecnología avanzada e innovación

Muchas empresas chinas de mecanizado CNC están invirtiendo en investigación y desarrollo, mejorando constantemente las técnicas de producción y aportando constantemente componentes innovadores para bicicletas.

Conclusión

En la industria de la bicicleta, el mecanizado CNC es una tecnología esencial que permite producir componentes críticos con una precisión, resistencia y eficacia inigualables. Las piezas de bicicleta mecanizadas mediante CNC abarcan desde bielas y cambios hasta cuadros y bujes, y garantizan la proverbial necesidad de alta durabilidad, construcción ligera y el mejor rendimiento. Esta mejora hace que los componentes mecanizados mediante CNC sean ideales para el ciclismo de alto rendimiento, ya que permite fabricar los componentes con materiales avanzados como aluminio, titanio y compuestos de carbono. El mecanizado CNC tiene más ventajas que la durabilidad y el rendimiento. El proceso de fabricación que utilizamos es el de producción a gran escala, pero manteniendo los estándares de alta calidad, de manera que cada pieza se construye según una especificación precisa. Además, el mecanizado CNC permite la personalización, por lo que los ciclistas pueden adaptar sus bicicletas a sus necesidades y preferencias personales.

China domina actualmente la industria CNC como cadena de suministro al mercado mundial. Con el progreso continuo de la tecnología ciclista, el mecanizado CNC tendrá una función aún mayor en el crecimiento de la industria, ayudando a impulsar los avances de la aerodinámica, el peso y la resistencia de los materiales. Tras invertir en componentes de bicicleta mecanizados mediante CNC, los fabricantes y usuarios de bicicletas dispondrán de bicicletas que funcionarán durante más tiempo, serán fiables y ofrecerán un rendimiento de alto nivel, lo que hará que el ciclismo sea eficiente y agradable.

Preguntas más frecuentes (FAQ)

1. ¿Cuáles son las ventajas del mecanizado CNC de piezas de bicicleta?

Los componentes de las bicicletas se fabrican con precisión, durabilidad, constancia y las 24 horas del día mediante mecanizado CNC. Así se consiguen piezas ligeras, pero resistentes, que mejoran el rendimiento y permiten la personalización.

2. ¿Qué tipo de materiales se utilizan en los componentes de bicicleta mecanizados mediante CNC?

Las aleaciones de aluminio son materiales comunes, 6061-T6, 7075-T6, titanio Ti-6Al-4V, compuestos de fibra de carbono, acero de alta resistencia 4130 cromoly y plásticos como nylon, policarbonato.

3. ¿Por qué China se ha convertido en el principal productor de piezas mecanizadas CNC para bicicletas?

China es el líder del mercado mundial de fabricantes de bicicletas gracias a su producción a bajo coste, su avanzada tecnología CNC, su capacidad para producir en masa y su alto nivel de control de calidad.

4. ¿Qué ventajas aporta el mecanizado CNC a los componentes de las bicicletas?

Mediante el mecanizado CNC, las piezas de bicicleta adquieren tolerancias precisas, eliminan las zonas débiles y ofrecen mejores propiedades de material que dan como resultado piezas duraderas y resistentes.

5. ¿Cuáles son las piezas de bicicleta mecanizadas por CNC más duraderas?

Los cuadros, horquillas, bielas, bujes y pinzas de freno mecanizados por CNC se encuentran entre las piezas de bicicleta mecanizadas por CNC más duraderas y están pensados para soportar algunas de las peores condiciones de conducción sin sacrificar el rendimiento.

Dejar una respuesta

¿Quiere participar en el debate?No dude en contribuir.