Hva er overstøping? Alt du trenger å vite

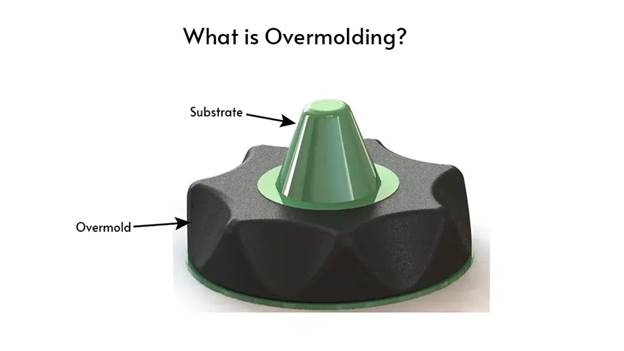

Overstøping er å lage et produkt ved å føye sammen to eller flere materialer til ett produkt. Det brukes i de fleste bransjer, for eksempel elektronikk, medisinsk utstyr, bilindustrien og forbrukerprodukter. Det gjøres ved å støpe over et grunnmateriale, et såkalt overmold, over et grunnmateriale, et såkalt substrat.

Overstøping gjøres for å forbedre produktenes estetikk, levetid og funksjonalitet. Det gjør det mulig for produsentene å kombinere det ene materialets styrke med det andre materialets fleksibilitet eller mykhet. Dette gjør produktene mer komfortable, lettere å håndtere og mer holdbare.

Overstøping dukker opp i gjenstander som vi bruker til daglig. Det gjelder blant annet tannbørstehåndtak og telefonvesker, men også elektroverktøy og kirurgiske instrumenter, for å nevne noe av det som brukes i moderne produksjon. Når man kjenner til overforming, er det lett å se hvor praktiske og trygge gjenstander i hverdagen er.

Hva er overstøping?

Overstøping er en prosedyre der ett produkt dannes av to materialer. Utgangsmaterialet kalles substrat og er vanligvis en hardplast som ABS, PC eller PP. Det har en strekkfasthet på 30-50 Mpa og en smeltetemperatur på 200-250 °C. Det andre materialet, overstøpningen, er mykt, f.eks. TPE eller silikon, med en Shore A-hardhet på 40-80.

Substratet får kjøle seg ned til 50-70 °C. Trykket som sprøytes inn i overformen er 50-120 MPa. Dette danner en sterk binding. Overforming forbedrer produktenes holdbarhet, styrke og holdbarhet.

En slik typisk gjenstand er en tannbørste. Håndtaket er av hard plast for å sikre styrke. Selve grepet er av myk gummi og er derfor behagelig å holde i. Denne grunnleggende applikasjonen viser hvordan overstøping kan brukes i det virkelige liv.

Overmolding gjelder ikke bare myke grep. Det brukes også til å dekke til elektroniske produkter, gi et objekt en fargerik dekorasjon og forlenge levetiden til et produkt. Denne fleksibiliteten gjør det til en av de mest anvendelige produksjonsmetodene i moderne tid.

Full prosess

Valg av materiale

Prosedyren for overstøping starter med valg av materialer. Substratet er vanligvis en hardplast som ABS, PC eller PP. De har en strekkfasthet på 30-50 Mpa og et smeltepunkt på 200-250 °C. Støpematerialet er vanligvis mykt, for eksempel TPE eller silikon, og har en Shore A-hardhet på 40-80. Det er nødvendig å velge materialer som er kompatible. Hvis det endelige produktet ikke tåler påkjenninger, kan det skyldes svikt i sammenføyningen av materialene.

Støping av substrat

Substratet ble hellet inn i formen med et trykk på 40-80 Mpa etter oppvarming til 220-250 °C. Når det er sprøytet inn, får det stivne til 50-70 °C for å gjøre det formstabilt. Denne prosessen tar vanligvis 30-60 sekunder i forhold til størrelsen og tykkelsen på delen. Toleransene er ekstremt høye, og avviket er vanligvis ikke mer enn +-0,05 mm. Avvik vil føre til at produktet påvirkes med hensyn til passform og produktkvalitet.

Klargjøring av formen som skal overstøpes

Etter avkjølingen overføres substratet forsiktig til en annen form, der oversprøytingen gjøres. Formen forvarmes til 60-80 °C. Forvarming eliminerer effekten av termisk sjokk og gjør også at overstøpningsmaterialet flyter jevnt over substratet. Forbehandling av støpeformen er nødvendig for å unngå hulrom, skjevheter eller dårlig liming i sluttproduktet.

Overmold Injeksjon

Trykket injiseres i substratet ved hjelp av 50-120 Mpa av overformingsmaterialet. Injeksjonstemperaturen er avhengig av materialet: TPE 200-230 °C, silikon 180-210 °C. Dette trinnet må være presist. Feil temperatur eller trykk kan føre til bobler, separasjon eller utilstrekkelig dekning.

Avkjøling og størkning

Etter injeksjonen kjøles delen ned slik at overformen stivner og får en sterk binding til underlaget. Avkjølingstiden varierer fra 30 til 90 sekunder, avhengig av tykkelsen på delene. De tynne områdene avkjøles raskere, mens de tykkere delene avkjøles langsommere. Tilstrekkelig avkjøling er nødvendig for å garantere jevn binding og minimere indre spenninger som kan forårsake sprekker eller deformasjon.

Utstøting og etterbehandling

Delen presses ut av formen etter at den er kjølt ned. Eventuelt overskudd, såkalt flash, skjæres bort. Komponenten kontrolleres med hensyn til overflatefinish og dimensjonsnøyaktighet. Dette sikrer at produktet har den kvaliteten som kreves, og at det er kompatibelt med de andre delene ved behov.

Testing og inspeksjon

Det siste trinnet er testing. Testtyper: Strekk- eller avskallingstester bestemmer styrken på bindingen, som vanligvis er 1-5 MPa. Shore A-tester brukes til å kontrollere hardheten på overformen. Defekter, som bobler, sprekker eller feiljustering, kan oppdages visuelt. Bare komponenter som er testet, blir sendt ut eller satt sammen til ferdige produkter.

Typer overstøping

To-skudds støping

To-shot-støping innebærer at én maskin støper to materialer. Støpingen skjer ved en temperatur på 220-250 °C og et trykk på 40-80 MPa, etterfulgt av den andre materialinjeksjonen, som foregår ved 50-120 MPa. Teknikken er rask og nøyaktig og egner seg godt når det dreier seg om et stort antall produkter, for eksempel gummigrep og soft-touch-knapper.

Innsatsstøping

Ved innsatsstøping er substratet allerede klargjort og satt inn i formen. Det dekkes med en overform, enten TPE eller silikon, som injiseres ved 50-120 MPa. Bindingsstyrken er vanligvis 1-5 MPa. Denne fremgangsmåten er typisk for verktøy, tannbørster og utstyr til helsevesenet.

Overstøping av flere materialer

Overstøping av flere materialer er en overstøping der det er mer enn to materialer i en enkelt del. Injeksjonsvarigheten for hvert materiale er i rekkefølge 200-250 °C, 50-120 MPa. Det gjør det mulig å lage kompliserte strukturer med harde, ømfintlige og dekkende seksjoner.

Overstøping har blitt brukt i applikasjoner

Bruksområdene for overstøping er svært varierte. Følgende er typiske eksempler:

Elektronikk

Telefonvesker har vanligvis hard plast med myke gummikanter. Knappene på fjernkontrollene er laget av gummi fordi de gir bedre berøring. Elektroniske komponenter beskyttes med overstøping, og brukervennligheten forbedres.

Medisinsk utstyr

Beskyttelsesforseglinger, kirurgiske instrumenter og sprøyter er vanligvis overstøpt. Myke produkter gjør det enklere å håndtere utstyret og gjør det også tryggere. Dette er avgjørende i medisinske applikasjoner der komfort og presisjon er viktig.

Bilindustrien

Overmolding brukes til å lage knapper, håndtak og tetninger med myk berøring som brukes i bilinteriør. Tetninger av gummi brukes til å hindre vann eller støv i å trenge inn i delene. Dette øker både komforten og holdbarheten.

Forbrukerprodukter

Overforming brukes ofte i tannbørstehåndtak, kjøkkenredskaper, elektroverktøy og sportsutstyr. Prosessen brukes til å legge til grep, beskytte overflater og tilføre design.

Industrielle verktøy

Overmolding brukes i verktøy som skrutrekkere, hammere og tenger, som brukes til å lage myke håndtak. Dette begrenser trettheten i hendene og øker sikkerheten ved bruk.

Emballasje

Overstøping av deler av emballasjen (f.eks. flasketopper eller beskyttelsesforseglinger) brukes for å forbedre håndtering og funksjonalitet.

Overstøping gjør det mulig for produsenten å produsere produkter som er funksjonelle, trygge og samtidig tiltalende.

Fordeler med overstøping

Det er mange fordeler med overstøping.

Forbedret grep og komfort

Produkter blir lettere å håndtere ved bruk av myke materialer. Dette gjelder verktøy, husholdningsprodukter og medisinsk utstyr.

Økt holdbarhet

Bruk av flere materialer øker produktets styrke. De harde og myke materialene garanterer produktets sikkerhet.

Bedre beskyttelse

Deksel eller tetninger til elektronikk, maskiner eller ømfintlige instrumenter kan legges til ved hjelp av overstøping.

Attraktiv design

Produktene er designet i ulike farger og teksturer. Dette forsterker image og merkevarebygging.

Ergonomi

Myke grep minimerer tretthet i hånden og gjør det mer behagelig å arbeide med gjenstander eller utstyr over lengre tid.

Allsidighet

Overmolding kan brukes i en rekke ulike materialer og kan brukes til å forme intrikate former. Dette gjør det mulig for produsentene å utvikle innovative produkter.

Utfordringer ved overstøping

Det er også noen utfordringer ved overstøping, som produsentene bør ta hensyn til:

Materialkompatibilitet

Ikke alle materialer binder godt. Enkelte kombinasjoner må kanskje limes eller overflatebehandles.

Høyere kostnader

Fordi det innebærer ekstra materialer, støpeformer og produksjonstrinn, kan overstøping øke produksjonskostnadene.

Kompleks prosess

Formens utforming, trykk og temperatur må være strengt regulert. Selv den minste feil kan føre til defekter.

Produksjonstid

Støping To-trinns støping kan kreve mer tid enn støping av ett materiale. Ny teknologi, som for eksempel to-shot-støping, kan imidlertid redusere dette tidsforbruket.

Begrensninger i design

Komplekse former kan kreve tilpassede støpeformer, og dette kan være kostbart å lage.

Likevel har ikke disse nedslående problemene hindret overstøping, siden det forbedrer kvaliteten på produktene og ytelsen.

Designprinsipper for overstøping

Overmolding er en design der basen er laget av et materiale, og støpeformen er laget av et annet materiale.

Materialkompatibilitet

Velg materialene som skal limes. Overform og substrat bør være kompatible med hverandre når det gjelder kjemiske og termiske egenskaper. Lignende materialer som har smeltepunkter som ligger nær hverandre, minimerer sjansene for svak binding eller delaminering.

Veggtykkelse

Hold veggtykkelsen konstant, slik at det blir en jevn flyt av materialet. Ujevne vegger kan føre til feil som synkemerker, hulrom eller skjevheter. Veggene er vanligvis mellom 1,2 og 3,0 mm av ulike materialer.

Utkast til vinkler

Preg vinkler på vertikale flater for å lette utstøpingen. En vinkel på 1- 3 grader bidrar til å unngå skader på substratet eller overstøpen under avformingen.

Avrundede hjørner

Unngå skarpe hjørner. Avrundede kanter forbedrer materialflyten under injeksjon, og spenningskonsentrasjonen reduseres. Anbefalt hjørneradius er 0,5-2 mm.

Funksjoner for liming

Det lages groper eller riller, eller det lages sammenlåste strukturer for å øke den mekaniske bindingen mellom substratet og overformen. Disse strukturene gir økt avskallings- og skjærstyrke.

Ventilasjon og plassering av porter

Installer ventiler som gjør det mulig for luft og gasser å slippe ut. Plasser injeksjonsportene på andre steder enn de følsomme områdene for å oppnå en homogen strømning som unngår kosmetiske feil.

Hensyn til krymping

Tenk på variasjonen i materialenes krymping. Krympingen av termoplast kan være så liten som 0,4-1,2, og elastomerer kan være 1-3%. Med riktig design unngår du forvrengning og dimensjonsfeil.

Teknisk beslutningstabell: Er overstøping riktig for ditt prosjekt?

| Parameter | Typiske verdier | Hvorfor det er viktig |

| Substratmateriale | ABS, PC, PP, Nylon | Gir strukturell styrke |

| Underlagets styrke | 30-70 MPa | Bestemmer stivhet |

| Overformingsmateriale | TPE, TPU, silikon | Gir bedre grep og tetting |

| Overformens hardhet | Strand A 30-80 | Kontrollerer fleksibilitet |

| Injeksjonstemperatur | 180-260 °C | Sikrer riktig smelting |

| Injeksjonstrykk | 50-120 MPa | Påvirker liming og fylling |

| Bindingsstyrke | 1-6 MPa | Måler lagets vedheft |

| Veggtykkelse | 1,2-3,0 mm | Forhindrer defekter |

| Avkjølingstid | 30-90 sekunder | Påvirker syklustiden |

| Dimensjonell toleranse | ±0,05-0,10 mm | Sikrer nøyaktighet |

| Krympefrekvens | 0,4-3,0 % | Forhindrer vridning |

| Verktøykostnader | $15k-80k | Høyere initialinvestering |

| Ideelt volum | >50 000 enheter | Forbedrer kostnadseffektiviteten |

Deler laget ved hjelp av overstøping

Verktøyhåndtak

Overmolding brukes til å skape en hard kjerne og et mykt gummigrep i mange håndverktøy. Dette øker komforten og minimerer tretthet ved bruk av hånden, og gir bedre kontroll over bruken.

Forbrukerprodukter

De vanligste produktene, som tannbørster, kjøkkenutstyr og verktøy som krever strøm, bruker vanligvis overforming. Myke grep eller puter bidrar til å forbedre ergonomien og levetiden.

Elektronikk

Telefonvesker, fjernkontroller og beskyttelseshus er blant de vanligste bruksområdene for overstøping. Det gir også støtdemping, isolasjon og en myk berøringsoverflate.

Bilkomponenter

Overformede knapper, tetninger, pakninger og håndtak er et vanlig innslag i bilinteriøret. Soft-touch-systemer forbedrer komforten, støyen og vibrasjonene.

Medisinsk utstyr

Overstøping brukes i medisinsk utstyr som sprøyter, kirurgiske instrumenter, håndholdte gjenstander og lignende. Prosessen garanterer gjennomgående sikkerhet, nøyaktighet og godt grep.

Råmaterialer i overstøping

Valg av materiale er viktig. Vanlige substrater inkluderer:

Hardplast som polypropylen (PP), polykarbonat (PC) og ABS.

Metaller i bruksområder

Overformingsmaterialene er vanligvis:

- Myk plast

- Gummi

- Termoplastiske elastomerer av nylon (TPE)

- Silikon

Valg av materiale er basert på bruken av produktet. For eksempel kreves det biokompatible materialer i medisinske apparater. Elektronikk krever materialer som er isolerende og beskyttende.

Beste praksis for design av overstøpte deler

Utformingen av deler som skal overstøpes, må være godt gjennomtenkt for å oppnå høy grad av liming, attraktivt utseende og høy kvalitet. Ved å følge etablerte retningslinjer for design bidrar man til å minimere feilprosenten, og kvaliteten på produktene blir jevn.

Velg materialer som er kompatible

Overstøpingen avhenger av materialvalget. Overformen og det underliggende materialet må ha en god forbindelse. Råvarer som smelter like raskt og har de samme kjemiske egenskapene, har sterkere og mer pålitelige bindinger.

Design for sterk liming

God mekanisk binding mellom delens design og selve designet bør støttes. Underskjæringer, riller og sammenlåsende former er noen av funksjonene som gjør det mulig for det overstøpte materialet å holde basisdelen godt fast. Dette minimerer sjansene for separasjon under bruk.

Hold veggtykkelsen på riktig måte

En jevn tykkelse på veggene gjør det mulig for materialet å flyte i støpeprosessen. Hvis tykkelsen ikke er jevn, kan det føre til synkemerker, hulrom eller svake seksjoner i komponenten. En symmetrisk design forbedrer både styrken og utseendet.

Bruk tilstrekkelige trekkvinkler

Utkastvinkler forenkler prosessen med å ta ut delen fra støpeformen. Friksjon og skader kan minimeres ved utstøting ved hjelp av riktig utkast, og dette er spesielt nyttig ved komplekse overstøpte deler.

Unngå skarpe hjørner

Spisse kanter kan forårsake spenningspunkter og begrense materialflyten. Avrundede kanter og flytende resultater forbedrer styrken og gjør at den overstøpte massen flyter jevnt rundt komponenten.

Inkluder ventilasjonsfunksjoner

Under injeksjonen gjør god utlufting det mulig for innestengt luft og gasser å slippe ut. Med god utlufting kan man unngå luftlommer og overflatefeil, samt fylle formen halvveis.

Planlegg plassering av overstøpningsmateriale

Injeksjonspunktene skal ikke plasseres i nærheten av viktige funksjoner og kanter. Dette eliminerer opphopning av materialer, brudd i flyten og estetiske defekter i de eksponerte delene.

Optimaliser verktøyutformingen

Vellykket overstøping krever godt utformede støpeformer. Riktig plassering av porten, balanserte løpere og effektive kjølekanaler bidrar til å sikre jevn flyt og stabil produksjon.

Ta hensyn til materialkrymping

Ulike stoffer har ulik nedkjølingshastighet. Disse forskjellene bør konstruktørene ta hensyn til, slik at det ikke oppstår skjevheter, feiljusteringer eller dimensjonsproblemer i den ferdige delen.

Hvilke materialer brukes til overforming?

Overstøping gir produsentene muligheten til å blande ulike materialer for å oppnå visse mekaniske, funksjonelle og estetiske egenskaper. Valget av materiale avgjøres av dets styrke, fleksibilitet, komfort og miljøbestandighet.

Termoplast, ikke termoplast.

Det er en av de mest utbredte overstøpingskombinasjonene. Basismaterialet er en termoplastisk polymer, som er polykarbonat (PC). Deretter dekkes det med en mykere termoplast, for eksempel TPU. Denne kompositten gir bedre grep, komfort og overflatefølelse, uten at det går på bekostning av den strukturelle styrken.

Termoplast over metall

Denne teknikken bruker et termoplastisk materiale som støpes på toppen av en metalldel. Metaller som stål eller aluminium er vanligvis belagt med plast som polypropylen (PP). Dette bidrar til å beskytte mot korrosjon av metallet, redusere vibrasjoner og redusere støy under bruk.

TPE over elastomer.

Dette systemet består av et resirkulert substrat av hardplast, for eksempel ABS, med en fleksibel elastomer på toppen. Det brukes vanligvis i produkter som krever holdbarhet og fleksibilitet, for eksempel verktøyhåndtak og medisinsk utstyr.

Silikon over plast

Silikon kan også støpes over plastmaterialer som polykarbonat. Dette gir høy vannbestandighet, tetningsevne og lav taktil følelse. Det brukes ofte i medisinsk og elektronisk utstyr.

TPE over TPE

Det er også mulig å overstøpe ulike kvaliteter av termoplastiske elastomerer. Dette gjør det mulig for produsentene å produsere produkter med ulike teksturer, farger eller funksjonsområder i én og samme del.

Er overstøping det riktige valget?

Når produktet ditt krever styrke, komfort og holdbarhet på samme tid, overstøping er den riktige beslutningen å ta. Det er spesielt egnet for komponenter som trenger et mykt håndtak, slagfasthet eller ekstra beskyttelse, uten at det krever flere monteringsprosesser. Overstøping kan brukes på produkter som ofte berøres, for eksempel verktøy, medisinsk utstyr eller til og med elektroniske kabinetter.

Likevel er det ikke alle prosjekter som kan overstøpes. Det er normalt forbundet med økte verktøykostnader og intrikat design av støpemønster i motsetning til støping av enkeltmateriale. Når produksjonsmengdene er små eller produktdesignet er grunnleggende, kan de tradisjonelle støpeprosessene vise seg å være rimeligere.

En vurdering av materialkompatibilitet, produksjonsvolum, krav til funksjonalitet og budsjett i den innledende designfasen vil bidra til å avgjøre om en overstøpningsløsning er den mest effektive løsningen for ditt prosjekt.

Eksempler på overstøping i det virkelige liv

Tannbørster

Håndtaket er av hardplast. Grepet er av myk gummi. Dette gjør det lettere å rengjøre tennene.

Telefonvesker

Enheten er dekket med hard plast. Fallstøt absorberes av myke gummikanter.

Elektroverktøy

Håndtakene er overstøpt i gummi for å minimere vibrasjoner og øke sikkerheten.

Bilinnredning

Kontrollratt og knapper er som regel myke i følelsen, noe som gjør brukeropplevelsen bedre.

Følgende eksempler viser hvordan overstøping forbedrer brukervennlighet, sikkerhet og design.

Sincere Tech - Din Hi-Fi-partner i alle typer støping

Sincere Tech er en pålitelig produksjonspartner som arbeider med alle former for støping, for eksempel sprøytestøping og overstøping av plast. Vi bistår kundene med design og masseproduksjon av produkter med presisjon og effektivitet. Med høyteknologi og kompetent ingeniørkunst leverer vi deler av høy kvalitet til bilindustrien, medisin-, elektronikk- og forbrukermarkedet. Besøk Plas.co for å bli bedre kjent med hva vi kan og tilbyr.

Konklusjon

Overmolding er en fleksibel og nyttig produksjonsteknikk. Det er en prosess som innebærer en kombinasjon av to eller flere materialer for å gjøre produktene sterkere, tryggere og mer komfortable. Teknikken brukes i stor utstrekning innen elektronikk, medisinsk utstyr, bilkomponenter, husholdningsapparater og industriverktøy.

Dette gjøres ved et nøye valg av materiale, nøyaktig form på formene og ved å sørge for at temperatur og trykk holdes under kontroll. Overforming har betydelige fordeler, selv om det også byr på noen utfordringer, som økte kostnader og lengre produksjonstid.

Overformede produkter er mer holdbare, ergonomiske, tiltalende for øyet og funksjonelle. Overforming har blitt en uatskillelig del av moderne produksjon, fra hverdagsprodukter som tannbørster og telefonvesker til mer seriøse produkter som medisinsk utstyr og bilinteriør.

Når vi vet om overstøping, kan vi være takknemlige for at det er enkle designbeslutninger som bidrar til å gjøre produktene mer praktiske å bruke og mer holdbare. En så liten, men likevel viktig prosess bidrar til å forbedre kvaliteten og funksjonaliteten til varene vi bruker i hverdagen.

Legg igjen et svar

Vil du delta i diskusjonen?Du er velkommen til å bidra!