Het spuitgieten is een relevante technologie in de hedendaagse productie. Het wordt gebruikt om metaal of andere elementen aan kunststof te bevestigen. Het proces zorgt voor een uniform, sterk en sterk onderdeel. Als alternatief voor de stapsgewijze techniek waarbij stukken na het gieten in elkaar gezet moeten worden, versmelt de techniek van het spuitgieten ze. Dit bespaart arbeid en tijd en verhoogt de kwaliteit van het product.

China is een mammoet op het gebied van insert molding. Het biedt kostenefficiënte productie. In het land zijn fabrieken van hoog niveau en geschoolde arbeidskrachten gevestigd. China is een producent van multifunctionele materialen. Het leidt de wereldwijde productie.

Dit artikel bespreekt insert molding, het proces, types insert, materialen, ontwerp, beschikbare richtlijnen, het gebruik, de voordelen en de vergelijking met gietprocessen in de hedendaagse productie.

Wat is invoegen?

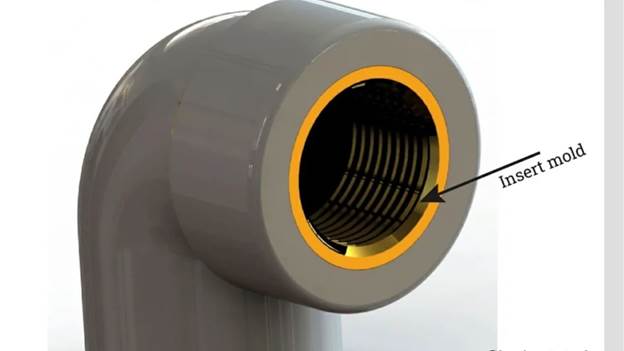

Insert molding is een proces voor het gieten van kunststof. Een geassembleerd onderdeel, meestal een metalen onderdeel, wordt in een matrijs geplaatst. In de volgende stap wordt er gesmolten kunststof omheen gespoten. Wanneer de kunststof hard wordt, wordt het kunststof inzetstuk een onderdeel van het eindproduct. De techniek wordt gebruikt in de elektronica- en auto-industrie en ook in de medische apparatuurindustrie.

Het grote voordeel van insert molding is sterkte en stabiliteit. Met metaal ingevoegde kunststofonderdelen zijn sterker in termen van mechanische sterkte. Ze kunnen ook worden geschroefd en slijten minder naarmate de tijd vordert. Dit is vooral essentieel bij onderdelen die vaak geschroefd of gebout moeten worden.

Soorten inzetstukken

De inzetstukken die gebruikt worden bij het spuitgieten hebben verschillende variëteiten, die afhankelijk van het doel gebruikt worden.

Metalen inzetstukken

Metalen inzetstukken zijn het meest gangbaar. Deze zijn van staal, messing of aluminium. Ze worden gebruikt op gaten met schroefdraad voor structurele of mechanische sterkte.

Elektronische invoegtoepassingen

Elektronische componenten die in de vorm van kunststof gegoten kunnen worden, zijn sensoren, connectoren of kleine circuits. Dit garandeert hun veiligheid en de vermindering van assemblageprocessen.

Andere materialen

Sommige inzetstukken zijn gemaakt van keramiek of composieten voor speciale doeleinden. Ze worden gebruikt wanneer hittebestendigheid of isolatie vereist is.

Het juiste inzetstuk kiezen

De beslissing hangt af van de rol van het onderdeel en het type kunststof. De belangrijkste zijn compatibiliteit, sterkte en duurzaamheid.

Het proces van invoegen

Bij eenstaps spuitgieten wordt een metalen of ander element in een kunststof gereedschap verwerkt. Het inzetstuk wordt in het uiteindelijke product geplaatst. Dit is een sterker en sneller proces in vergelijking met de assemblage van onderdelen die volgt.

Het inzetstuk voorbereiden

Het inzetstuk wordt gespoeld om al het vuil, vet of roest eruit te halen. Af en toe wordt het bedekt met een coating of wordt het ruw gemaakt, zodat het aan plastic vastkleeft. Het wordt niet vernietigd door heet plastic als het wordt voorverwarmd tot 65-100 °C.

Het inzetstuk plaatsen

De insert wordt met veel zorg in de mal geplaatst. Robots kunnen het in grote fabrieken plaatsen. Pennen of klemmen houden het stevig vast. De plaatsing van de rechterkant voorkomt beweging tijdens het gieten.

Plastic injecteren

Dit wordt bereikt door gesmolten kunststof rond de insert te injecteren. De temperatuur ligt tussen 180 en 343°C. De druk is 50-150 MPa. Om sterk te zijn, moet de houddruk 5-60 seconden zijn.

Koeling

Het is een stolling van het plastic. Kleinere onderdelen hebben 10-15 seconden nodig en grotere onderdelen 60 seconden of langer. Koelkanalen voorkomen het opwarmen.

Het onderdeel uitwerpen

De mal en de uitwerppennen dwingen het onderdeel naar buiten. Daarna kan kleine nabewerking of bijsnijden volgen.

Belangrijke punten

De uitzetting van metaal en kunststof is niet hetzelfde. Voorverwarmen en een constante, gecontroleerde matrijstemperatuur verlagen de spanning. Dit wordt gedaan door het gebruik van sensoren in moderne machines om uniformiteit te bereiken in de resultaten wat betreft druk en temperatuur.

Belangrijkste parameters:

| Parameter | Typisch industrieel bereik | Effect |

| Injectietemperatuur | 180-343 °C | Afhankelijk van de kunststofsoort (hoger voor PC, PEEK) |

| Injectiedruk | 50-150 MPa (≈7.250-21.750 psi) | Moet hoog genoeg zijn om de inlegoppervlakken te vullen zonder ze te verplaatsen |

| Injectietijd | 2-10 s | Korter voor kleine onderdelen; langer voor grotere onderdelen |

| Houddruk | ~80% injectiedruk | Toegepast na opvullen om materiaal dichter te maken en krimpleemtes te verminderen |

| Wachttijd | ~5-60 s | Afhankelijk van materiaal en onderdeeldikte |

Soorten veelvoorkomende injecties die vorm moeten krijgen

Er bestaan verschillende soorten inzetstukken voor spuitgieten, afhankelijk van het gebruik. Elk van de types draagt bij tot de sterkte en de prestaties van het uiteindelijke onderdeel.

Metalen inzetstukken met schroefdraad

Schroefdraadinzetstukken kunnen van staal, messing of aluminium zijn. Ze maken het mogelijk om een aantal keren te schroeven en te bouten zonder dat het plastic kapot gaat. Dit laatste komt vaak voor in auto's, huishoudelijke apparaten en elektronica.

Perspassing inzetstukken

De press-fit inzetstukken zijn de inzetstukken die zonder extra bevestiging in een gegoten onderdeel worden geïnstalleerd. Als het plastic afkoelt, houdt het de insert vast en stabiliseert het zeer goed en krachtig.

Heat-Set inzetstukken

Dit wordt gevolgd door het heat-setten van de inzetstukken. Na afkoeling versmelt de hete insert tot op zekere hoogte met de omringende kunststof, waardoor een zeer sterke verbinding ontstaat. Ze worden meestal gebruikt in thermoplasten, zoals nylon.

Ultrasone inzetstukken

In een trilling worden ultrasone inzetstukken geplaatst. Het plastic smelt in het gebied rond het inzetstuk en wordt hard om een nauwsluitende pasvorm te creëren. Het is een nauwkeurige en snelle methode.

Het juiste inzetstuk kiezen

De keuze voor rechts en links wordt bepaald door het type kunststof, het ontwerp van het onderdeel en de verwachte belasting. De keuze van metalen inzetstukken is gebaseerd op sterkte en de speciale inzetstukken, zoals de heat-set inzetstukken en ultrasone inzetstukken, zijn geëvalueerd op basis van precisie en duurzaamheid.

Ontwerpregels in de injectie-spuitgietindustrie

Het ontwerp van onderdelen die met behulp van molding worden ingevoegd, moet goed worden gepland. Een nauwkeurig ontwerp zorgt voor een hoge hechting, precisie en duurzaamheid.

Plaatsing van de inzetstukken

De inzetstukken worden geplaatst op een plek waar ze goed ondersteund worden door kunststof. Ze mogen niet te dicht bij muren of dunne randen zitten, omdat dit kan leiden tot scheuren of kromtrekken.

Plastic Dikte

Zorg er altijd voor dat de wanden rondom het inzetstuk even dik zijn. Door een abrupte dikteverandering kan ongelijkmatige afkoeling en krimp optreden. Het inzetstuk heeft meestal een dikte van 2-5 mm, wat voldoende is voor sterkte en stabiliteit.

Materiaal compatibiliteit

Neem plastic en vul het met zelfklevende materialen. Een voorbeeld is nylon dat gebruikt kan worden met inzetstukken van messing of roestvrij staal. Mengsels die overmatig warm worden, moeten worden vermeden.

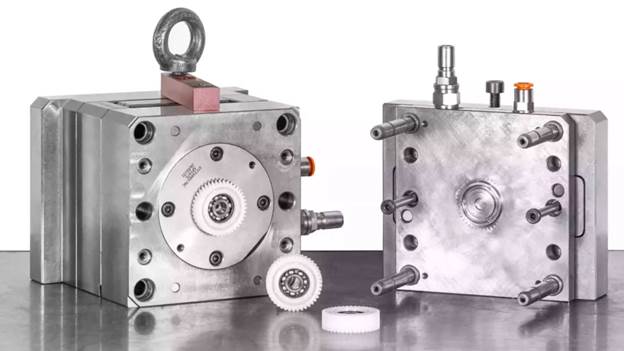

Vormontwerp

Zorg voor een goede positie van de poort en een goede koeling van de mal. De kunststof moet vrij over de insert kunnen bewegen en mag geen lucht insluiten. De temperaturen worden gestabiliseerd door kanalen en kromtrekken wordt voorkomen.

Toleranties

Correcte toleranties van de insteekcomponenten van het ontwerp. Er is slechts een kleine speling van 0,1-0,3 mm nodig om de insert perfect te laten passen zonder los of hard te zijn.

Versterkingseigenschappen

De inzetstukken moeten worden verstevigd met ribben, nokken of hoekprofielen. Bij gebruik worden deze eigenschappen wijd verspreid, waardoor scheuren of verschuiven van de inzetstukken wordt voorkomen.

Ongeschikte overmoldmaterialen voor gebruik in een insert-molding proces

Het ideale proces is het spuitgieten; het plastic wordt echter gemakkelijk gesmolten en vloeit gemakkelijk door het spuitgietproces. De kunststof moet ook aan de insert vastzitten om een robuust onderdeel te maken. De voorkeur gaat uit naar thermoplasten omdat die de juiste smelt- en vloei-eigenschappen hebben.

Styreen Acrylonitril Butadieen Styreen

ABS is niet alleen dimensionaal, maar ook gemakkelijk om mee te werken. Het is het best toepasbaar in consumentenelektronica en andere producten die een hoge mate van nauwkeurigheid en stabiliteit vereisen.

Nylon (polyamide, PA)

Nylon is sterk en flexibel. Het wordt meestal gelast aan metalen inzetstukken om een structureel product te maken, bijvoorbeeld autobeugels of bouwonderdelen.

Polycarbonaat (PC)

Polycarbonaat is niet alleen scheurvrij maar ook taai. Het wordt vooral gebruikt voor elektronicabehuizingen, medische apparatuur en andere apparatuur die duurzaamheid vereist.

Polyetheretherketon (PEEK)

PEEK heeft een concurrentievoordeel ten opzichte van hitte en chemicaliën. Het zou van toepassing zijn op de high-performance engineering, lucht- en ruimtevaart en medische gebieden.

Polypropyleen (PP)

Polypropyleen is niet viskeus en reageert ook niet op een groot aantal chemicaliën. Het wordt gebruikt voor huishoudelijke en consumentengoederen en voor auto-onderdelen.

Polyethyleen (PE)

Polyethyleen is goedkoop en ook elastisch. Het wordt voornamelijk gebruikt in verlichting, bijvoorbeeld voor verpakkingen of beschermende koffers.

Thermoplastisch polyurethaan (TPU) en thermoplastisch elastomeer (TPE)

TPU en TPE zijn rubberachtig, zacht en elastisch. Ze zijn perfect voor het overspuiten van handgrepen, afdichtingen of onderdelen die schokabsorptie vereisen.

Het juiste materiaal kiezen

De keuze van het overmoldmateriaal wordt bepaald door de functionaliteit van het onderdeel, de taak van de insert en de werking ervan. Het moet ook een goed vloeiende kunststof zijn die aan de insert hecht en bovendien de vereiste sterkte en flexibiliteit biedt.

Onderdeelgeometrie en plaatsing van inzetstukken:

Deze functie is van toepassing op alle onderdelen.

Onderdeelgeometrie en plaatsing van inzetstukken:

Het is een functie die op elk onderdeel kan worden toegepast.

De retentie van de insert is afhankelijk van de vorm van het onderdeel. De plaatsing van de insert moet zodanig zijn dat er voldoende kunststof omheen zit. Een verzekering mag niet te dicht bij randen of smalle wanden zitten, omdat dit kan barsten of buigen.

Het plastic rond het inzetstuk moet gelijkmatig van dikte zijn. Een plotselinge verandering in dikte kan leiden tot niet-uniforme afkoeling of inkrimping. In het geval van de insert is een normale dikte van 2-5 mm plastic voldoende voor sterkte en stabiliteit.

De ontwerpkenmerken die kunnen worden gebruikt om de insert te ondersteunen zijn ribben, nokken en hoekplaten. Deze helpen bij het verspreiden van spanning en het afremmen van beweging. Als het inzetstuk eenmaal correct is geïnstalleerd, is men er zeker van dat het onderdeel op zijn plaats zit en dat het effectief werkt.

Technische vergelijking van thermoplasten voor het spuitgieten van inzetstukken

| Materiaal | Smelttemp (°C) | Vormtemp (°C) | Injectiedruk (MPa) | Treksterkte (MPa) | Slagvastheid (kJ/m²) | Krimp (%) | Typische toepassingen |

| ABS | 220-260 | 50-70 | 50-90 | 40-50 | 15-25 | 0.4-0.7 | Consumentenelektronica, behuizingen |

| Nylon (PA6/PA66) | 250-290 | 90-110 | 70-120 | 70-80 | 30-60 | 0.7-1.0 | Automotive beugels, dragende onderdelen |

| Polycarbonaat (PC) | 270-320 | 90-120 | 80-130 | 60-70 | 60-80 | 0.4-0.6 | Elektronicabehuizingen, medische apparatuur |

| PEEK | 340-343 | 150-180 | 90-150 | 90-100 | 15-25 | 0.2-0.5 | Ruimtevaart, medische, chemische toepassingen |

| Polypropyleen (PP) | 180-230 | 40-70 | 50-90 | 25-35 | 20-30 | 1.5-2.0 | Auto-onderdelen, verpakking |

| Polyethyleen (PE) | 160-220 | 40-60 | 50-80 | 15-25 | 10-20 | 1.0-2.5 | Verpakking, behuizingen met lage belasting |

| TPU/TPE | 200-240 | 40-70 | 50-90 | 30-50 | 40-80 | 0.5-1.0 | Handgrepen, afdichtingen, flexibele onderdelen |

De voordelen van het inlegprofiel

Sterke en duurzame onderdelen

Bij het spuitgieten worden kunststof en metaal samengevoegd tot één geheel. Dit maakt de onderdelen sterk, robuust en keer op keer bruikbaar.

Minder montage en arbeid

Het inzetstuk wordt in de kunststof geplaatst en er is geen extra montage nodig. Dit bespaart tijd en arbeid en vermindert de kans op fouten tijdens de montage.

Precisie en betrouwbaarheid

Het inzetstuk wordt stevig vastgemaakt aan de gietvorm. Dit garandeert dat de afmetingen hetzelfde zijn en dat de mechanische sterkte wordt verhoogd om de betrouwbaarheid van de onderdelen te vergroten.

Ontwerpflexibiliteit

Het maken van complexe ontwerpen met behulp van spuitgieten zou moeilijk zijn met conventionele assemblage. Het is mogelijk om metaal en kunststof in een nieuwe combinatie te gebruiken om aan functionele eisen te voldoen.

Kosteneffectiviteit

Insert molding vermindert ook materiaalverspilling en assemblagekosten bij grote productievolumes. Het verbetert de doeltreffendheid en de algehele kwaliteit van producten en is dus kosteneffectief op de lange termijn.

De toepassingen van het inzetgietwerk

Auto-industrie

De auto-industrie is een typische toepassing van inzetgieten. Plastic onderdelen hebben metalen inzetstukken die het onderdeel, zoals beugels, motoronderdelen en connectoren, stevigheid geven. Dit maakt assemblage minder en duurzaamheid meer.

Elektronica

Elektronica. Het voordeel van insert molding is hier dat het mogelijk is om connectoren, sensoren en circuits toe te voegen aan een plastic behuizing. Dit garandeert de veiligheid van de kwetsbare componenten en maakt het assemblageproces relatief eenvoudig.

Medische apparaten

De technologie van insert molding wordt veel gebruikt in medische apparatuur die een hoge mate van nauwkeurigheid en duurzaamheid vereist. Dit wordt toegepast bij de productie van chirurgische apparatuur, diagnostische apparatuur en duurzame kunststof-metaalcombinaties.

Consumentenproducten

Consumptiegoederen zoals elektrisch gereedschap, toestellen en sportuitrusting worden meestal gegoten met inzetgieten. Het versterkt en vereenvoudigt de assemblage van het proces en maakt ergonomische of complexe ontwerpen mogelijk.

Industriële toepassingen, lucht- en ruimtevaart.

De inzetgieten wordt ook gebruikt in zware industrieën en de ruimtevaart. Hoogwaardige kunststoffen die gevuld zijn met metaal hebben lichte en sterke onderdelen die hittebestendig en slijtvast zijn.

Gebruikte materialen

De werking van het spuitgieten vereist de juiste materialen voor het kunststof en het spuitgietmateriaal. De keuze zal leiden tot kracht, stabiliteit en uitvoer.

Metalen inzetstukken

Metalen inzetstukken worden meestal gebruikt omdat ze ruw en duurzaam zijn. Het bestaat voornamelijk uit staal, messing en aluminium. In onderdelen met een belasting kan staal worden gebruikt, messing kan niet corroderen en aluminium is licht.

Kunststof inzetstukken

Kunststof inzetstukken zijn corrosiebestendig en licht. Ze worden gebruikt in toepassingen met een lage belasting of in onderdelen die niet-geleidend zijn. Kunststof inzetstukken kunnen ook in complexe vormen worden gegoten.

De keramische en composiet inzetstukken.

Keramische en composiet inzetstukken worden gebruikt om hitte, slijtage of chemische weerstand te verkrijgen. Ze worden meestal gebruikt in de ruimtevaart, de medische sector en de industrie. Keramiek is bestand tegen hoge temperaturen en composieten zijn ook stijf maar hebben een lage thermische uitzetting.

Thermoplastische overmallen

Het omhulsel van de insert is thermoplastisch en meestal van kunststof. Beschikbare opties zijn ABS, Nylon, Polycarbonaat, PEEK, Polypropyleen, Polyethyleen, TPU en TPE. ABS is vormbaar en stabiel, Nylon is flexibel en sterk, en Polycarbonaat is een slagvast materiaal. TPU en TPE zijn zachte en rubberachtige materialen die worden gebruikt als afdichtingen of handgrepen.

Materiaal compatibiliteit

Kunststof en metaal moeten in verhouding tot elkaar groeien om rek of vervorming te voorkomen. De kunststoffen moeten aan het inzetstuk worden gelijmd om te voorkomen dat ze losraken. Bij kunststof inzetstukken moet het overmold-materiaal lijm krijgen om ervoor te zorgen dat het sterk wordt.

Tips voor materiaalselectie

Houd rekening met de belasting, temperatuur, chemische stoffen en blootstelling aan het ontwerp van het onderdeel. De metalen inzetstukken zijn duurzaam, de kunststof inzetstukken zijn licht en de keramiek is bestand tegen extreme omstandigheden. Het overmoldmateriaal moet aan alle functionele eisen kunnen voldoen.

Kostenanalyse

Met het ingevoegde plastic kan geld worden bespaard dat zou zijn gebruikt voor het bevestigen van losse onderdelen. De verlaging van de assemblageniveaus betekent een verlaging van het aantal arbeiders en een hogere productiesnelheid.

De initiële kosten voor gieten en gereedschap zijn hoger. Multiplex matrijzen met een set inserts in een bepaalde positie zijn duurder. De kosten per eenheid zijn echter lager als het productieniveau hoog is.

De materiaalkeuze is ook een kostenfactor. Kunststof inzetstukken zijn goedkoper dan metalen inzetstukken. PEEK is een hoogwaardige kunststof die duur is in vergelijking met de veelgebruikte kunststoffen, zoals ABS of polypropyleen.

In het algemeen zal de prijs van insert moulding minimaal zijn bij middelgrote tot grote productievolumes. Het bespaart assemblagetijd, verbetert de kwaliteit van de onderdelen en verlaagt de productiekosten op lange termijn.

De problemen met het gieten van inlegdelen

Ondanks de hoge efficiëntie van het spuitgieten, heeft het ook zijn problemen:

Thermische uitzetting: We zullen snelheidsverschillen hebben en dus kromtrekken in metaal en plastic.

Beweging invoegen: Inzetstukken kunnen al tijdens het injectieproces bewegen, tenzij ze stevig worden vastgezet.

Materiaal compatibiliteit: Niet alle kunststoffen zijn compatibel met alle metalen.

Kosten voor kleine series matrijzen maken en instellen: Het maken en instellen van matrijzen kan duur zijn bij zeer kleine hoeveelheden.

Deze problemen worden tot een minimum beperkt door goed te ontwerpen, de matrijzen voor te bereiden en het proces te controleren.

Toekomst van invoegen

Het spuitgieten bevindt zich in de ontwikkelingsfase. Nieuwe materialen, verbeterde machines en automatisering worden gebruikt om de efficiëntie te verhogen, en 3D-printen en hybride productieprocessen worden ook mogelijkheden. Het vermogen om lichtgewicht, sterke en precieze onderdelen te maken door de noodzaak van de onderdelen, zorgt ervoor dat het spuitgieten een belangrijk productieproces wordt.

Als het gaat om assistentie met Sincere Tech

In het geval van insert moulding en overmoulding, bieden wij hoogwaardige, correcte en betrouwbare spuitgietoplossingen bij Sincere Tech. Onze technologie en hand-craft werknemers zullen ervoor zorgen dat elk onderdeel zal zijn volgens uw specificatie. We zijn sterk in de langdurige, ingewikkelde en economische auto-, elektronische, medische en consumptiegoederen mallen. Uw productieproces is eenvoudig en efficiënt, en dit is te wijten aan onze doorlooptijden en een geweldige klantenservice. U verhuist naar Sincere Tech, en met het bedrijf zal werken in lijn met precisie, kwaliteit en uw succes. Vertrouw ons en hebben uw ontwerpen uitkomen voor ons correct, betrouwbaar, en aan de industriestandaarden.

Conclusie

Lijstwerk invoegen is een productieproces dat flexibel en effectief is. Het stelt ontwerpers in staat om een enkel krachtig onderdeel te gebruiken dat een combinatie is van metaal en kunststof. Het gebruik van insert moulding in de industrie door de jaren heen is te danken aan de voordelen zoals kracht, precisie en lage kosten. Maar met de vooruitgang in materialen en automatisering krijgt het steeds meer vertrouwen. De oplossing voor productie door insert molding is tijdsbesparing, kostenreductie en producten van hoge kwaliteit in de context van moderne productie.