A Comprehensive Guide to Peek Plastic Injection Molding

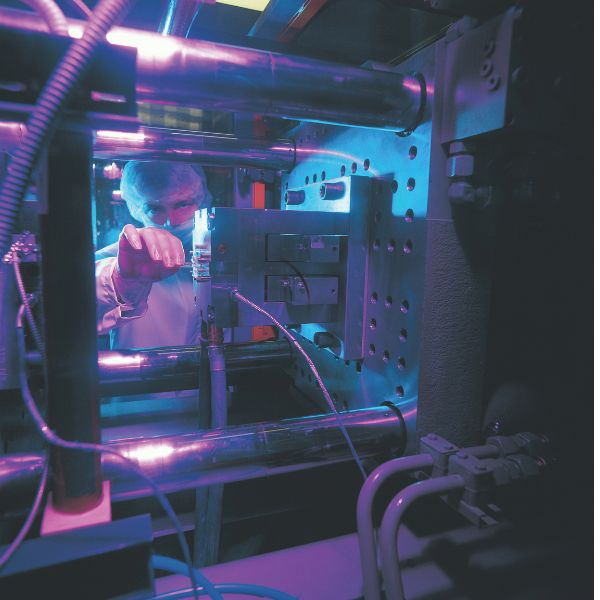

What is PEEK injection molding

Polyetheretherketone (PEEK) injection molding is a specialized manufacturing technique that involves the fabrication of complicated and high-performance components utilizing PEEK thermoplastic material. This process is also known as PEEK injection molding technology. PEEK is a high-performance engineering polymer that is well-known for the remarkable mechanical, thermal, and chemical capabilities that it presently possesses. In applications that demand a mix of high temperature resistance, chemical resistance, and mechanical strength, it is frequently selected as the material of choice.

Comprehending the Peek Material

Definition of Peek and Characteristics of Peek Peek, also known as polyetheretherketone, is a high-performance thermoplastic that is renowned for its remarkable mechanical, thermal, and chemical qualities. Because of its sturdy character, it is an excellent option for use in demanding situations where precision and durability are of the utmost critical importance.

Benefits of Using Peek in Injection Molding Techniques: The capacity of peek to keep its structural integrity even when subjected to harsh circumstances, in conjunction with its minimal moisture absorption and strong chemical resistance, makes it a perfect material for injection molding. The reasons that Peek is gaining popularity in a variety of industries are discussed in this section.

The PEEK Plastic Injection Molding Processing parameters

Many industries utilize thermoplastic polyetheretherketone (PEEK) because it’s robust, chemical-resistant, and stable at high temperatures. Injection casting is a popular PEEK method. This approach produces precise, complex pieces rapidly. To acquire the best PEEK injection molding outcomes, a few elements must be carefully considered.

People believe the temperature profile is crucial to PEEK injection molding. About 340 degrees Celsius melts PEEK. The barrel temperature must be high to provide smooth melt flow and mold filling. PEEK injection molding involves heating the metal tube to 350–400 degrees Celsius. The temperature varies on the PEEK type. The mold’s temperature must be carefully managed to prevent warping and ensure the product’s dimensions are steady.

PEEK injection molding still depends on injection speed. Due to its high viscosity, PEEK must be injected faster to flow effectively and fill the mold hole. However, high injection rates heat and break down the material, affecting mechanical characteristics and surface quality. Before commencing, inject at a moderate speed. Change it as needed based on part shape and mold design.

Pressure is another essential factor in PEEK injection molding. Because PEEK compresses easily, it’s important to pack the material into the mold with enough pressure to reduce holes and sink marks. Between 100 and 150 MPa is typical drilling pressure for PEEK. The range depends on part size and complexity. Matching injection pressure and speed is crucial for high-quality products.

PEEK injection molding requires more than temperature, speed, and pressure. Mold shape, gate placement, and cooling time also matter. Avoid gas traps and ensure high-quality products by venting properly. To reduce gate residue and stress, gate design and installation must be carefully considered. For optimal crystallinity and size stability, choose the appropriate cooling duration.

PEEK injection molding requires careful consideration of temperature, speed, pressure, and mold form to achieve the optimum results. Finally, this is crucial for optimal results. If they monitor these aspects and streamline the process, they may create high-quality PEEK parts with good mechanical qualities and accurate measurements. Because high-performance materials are becoming more prevalent in many sectors, learning PEEK injection molding is crucial to staying competitive.

IV. Key Considerations for Peek Plastic Injection Molding

Temperature Control: Maintaining optimal temperatures during Peek injection molding is a critical factor. This segment explores the importance of temperature control, the challenges involved, and how manufacturers overcome them.

Pressure Regulation: Precision in pressure regulation is a key consideration for successful Peek plastic injection molding. We delve into the intricacies of pressure control, its impact on the molding process, and strategies for achieving consistent results.

Molding Design for Peek: The design of molds plays a pivotal role in Peek injection molding. This part of the article discusses how molds are tailored to accommodate Peek’s unique characteristics, ensuring flawless production.

Quality Assurance and Testing: Ensuring the quality of Peek-molded products involves rigorous testing. From material inspection to post-molding checks, this section explores the comprehensive quality assurance measures adopted in Peek injection molding.

Advantages of Peek Plastic Injection Molding

Peek injection molding is common for plastics. This injection moulding employs polyetheretherketone (PEEK) to make durable products. below we will explain why peek plastic injection molding is best for many companies.

Peek plastic injection molding has several benefits, but one of the most important is that the material works well. PEEK is strong, rigid, and chemical-resistant, therefore people like it. A somewhat crystalline thermoplastic. It can withstand 300 degrees Celsius, making it ideal for heat-resistant applications. PEEK also resists wear and scratching, making it excellent for use in adverse environments where parts can be badly damaged.

Peek plastic injection molding lets you build complicated objects with precise tolerances. Injection molding can create complex shapes and features that conventional methods cannot. Thus, peek plastic injection molding is ideal for making unique pieces of diverse sizes.

Additionally, peek plastic injection molding offers cost-effective production options for many items. The automated process produces many components quickly and accurately. Plastic injection molding is cheaper than other processes for companies that want to create more. This is because making one thing is cheaper than other methods.

Environmentally friendly products can also be made by plastic injection molding. Waste and environmental effect can be reduced by recycling PEEK and using it to make new products. Injection moulding produces very little waste, making it even greener.

Finally, peek plastic injection molding benefits companies making high-quality, durable plastic items. Businesses are using peek plastic injection molding because it works well, can make complex designs, and is cost-effective and attractive. For companies who want to produce more items, “peak” plastic injection molding is reliable and flexible. Its ecologically friendly manufacture and versatility make it unique.

Challenges and Solutions PEEK injection molding

PEEK injection molding, while offering numerous advantages, comes with its own set of challenges. Addressing these challenges is crucial to ensuring the successful and consistent production of high-quality components. Here are some common challenges associated with PEEK injection molding and potential solutions:

An easy way to make good plastic parts for making things is through injection casting. The use of polyetheretherketone (PEEK) for injection casting has grown over the past few years. PEEK is a high-performance material that is great for use in fields like medicine, cars, and space travel because it is strong and doesn’t melt easily.

PEEK injection casting has a lot of good points, but it also has some bad points. Sometimes when shaping PEEK, problems happen. This blog post will talk about some of the most usual ones and how to fix them.

It’s hard to do PEEK injection casting because it has to be done at a very high temperature. It is much warmer for PEEK to melt than for most other thermoplastics, at about 343°C. This high of a temperature could lead to problems like heat damage, buckling, and a rough finish on the surface. You need to use special injection molding tools that can handle the high temperatures needed to work with PEEK to fix this case. If you use the right mold design and cooling devices, you can also keep the temperature down and avoid problems like warping and shrinking.

Something else that is bad about PEEK injection casting is that it is very thick. PEEK has a pretty high viscosity when compared to other thermoplastics. It can be hard to fill complicated molds and make sure that every part is the same quality because of this. You need to make sure that the speed, pressure, and temperature of the injection molding are all just right to clear this up. Fast and strong injection speeds can be used to make the PEEK move better in the mold. This can also make flaws like gaps and sink marks less likely.

Not only does PEEK have a high viscosity and working temperature, but it also wears down and releases from molds easily. You might have trouble getting PEEK parts out of the mold because they stick to metal. The best way to fix this is to use mold release agents and coats that work with PEEK. Also, using models made of sharpened steel and keeping them in good shape can help to keep them from wearing out and make them last longer.

In the end, there are many reasons why PEEK injection casting is a great way to make high-performance plastic parts. But it also has issues that need to be carefully fixed so that the production goes well. People who make things can mold PEEK and make good parts for many purposes as long as they know how to deal with issues like high processing temperatures, stickiness, and mold release.

Sincere Tech, which is ranked among the top ten mold makers in China, acknowledges the crucial significance that bespoke injection molding plays in getting to the point where manufacturing excellence is achieved. As a result of our vast experience in the business, we are pleased to provide services for bespoke injection molding that are of the highest possible quality and conform to the most stringent industry standards.

Each member of our team is a highly trained professional that is committed to providing you with great outcomes that are specifically designed to meet your requirements. We assure a smooth and effective manufacturing process from the very beginning to the very end by utilizing cutting-edge machinery and being driven by a dedication to innovation.

From the very beginning of the design process, we place a high priority on paying rigorous attention to detail in order to ensure that each and every product is tailored to your precise requirements. In order to optimize the design for injection molding, our experienced engineers will work closely with you and provide you with valuable insights and ideas. This collaborative approach results in solutions that are both cost-effective and of high quality, without sacrificing either.

Through the utilization of the one-of-a-kind characteristics of plastic materials, we are able to produce goods that not only have an exceptional surface quality but also have tight tolerances. This not only leads to a decrease in the costs associated with the waste rate, but it also provides a contribution to the enhancement of energy efficiency and improvements the overall user experience.

No matter what sector you work in or what application you have, our capabilities in custom injection molding can accommodate a wide variety of requirements. Our company possesses the knowledge and resources necessary to fulfill your requirements, regardless of whether you are looking for consumer goods, automotive components, electrical enclosures, medical equipment, or industrial parts.

By partnering with Sincere Tech China mold manufacturer for your custom injection molding requirements, you will be able to take advantage of our remarkable production capabilities, meticulous attention to detail, and unwavering dedication to providing goods of the highest quality that go beyond your expectations.

Please get in touch with us right away to obtain a price estimate if you are working on a plastic mold project and are seeking for mold suppliers to assist you.