アクリル射出成形は、高品質なプラスチック製品を製造する新しい技術と定義できる。この技術は、自動車産業、医療分野、消費財、電子機器など幅広い分野で応用されている。アクリル射出成形は、透明で強靭な魅力的な製品を作る技術として特に有名である。.

中国はアクリル成形ビジネスの主要な部分である。中国には、高品質のアクリル金型や部品を製造する工場が大量にある。費用対効果が高く、信頼性が高く、拡張性のある生産を国際市場に提供している。.

本稿では、射出成形のプロセス、金型の種類、用途、アクリル射出成形のベストプラクティスについて解説する。.

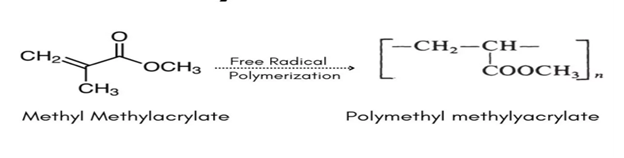

アクリル射出成形とは?

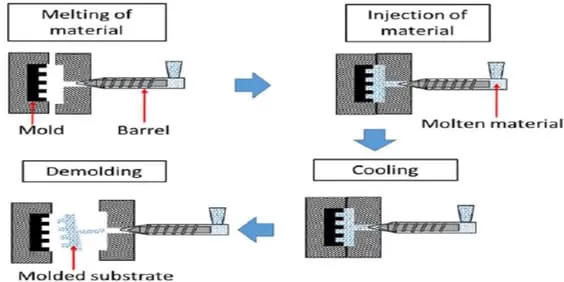

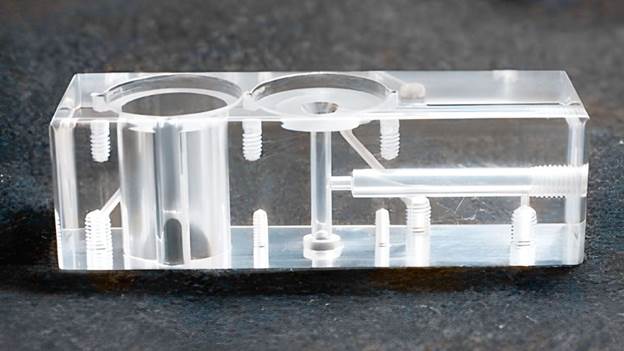

アクリル射出成形 は、アクリル樹脂を溶けるまで温め、金型に注入する航空機製造技術である。プラスチックは硬化し、所定の形状に固化する。この工程は、複雑で一貫性のある部品の大量生産に非常に有効である。.

アクリルのペレットは小さく、出発原料として使われる。これを加熱した樽に溶けるまで流し込む。その後、溶けたアクリルをアクリル型で高圧金型に注入する。金型は冷却され、開かれ、完成品が射出される。.

このプロセスは、他の成形方法とは異なり、速く、正確で、経済的である。必ずしも品質にこだわることなく、生産量を必要とする産業に適している。.

アクリル成形の利点

アクリル成形には数多くの利点がある。.

- 大きな透明度: アクリル製品は非常に透明である。視覚的であることが必要な場面でよく使用される。.

- 耐久性がある: アクリルは丈夫で傷がつきにくい。.

- 複雑な形: 他のプラスチックでは難しい複雑なデザインも可能だ。.

- 費用対効果: 金型を作れば、短時間で何千ものピースを作ることができる。.

- 一貫性: 各バッチは前のバッチと同じであり、品質は大量に確保されている。.

アクリル成形は迅速かつ正確であるため、産業界で品質とスピードが求められる場合には良い選択肢となる。.

アクリル射出成形が発見される

20世紀半ば、アクリル射出成形のプロセスを開発し始めたのは、メーカーがPMMAを成形する、より迅速で正確な方法を求めていたからである。以前は、アクリル成形の主な工程として鋳造が使われていたが、これは時間がかかり、手間のかかる工程だった。.

アクリルペレットを230~280℃の温度で溶かし、小さなアクリル型に注入する機械が、1940年代から1950年代にかけてドイツとアメリカの技術者によって発明された。この発明により、寸法が均一で複雑かつ高品質な部品の製造が可能になった。.

アクリルの射出成形技術は、自動車、医療機器、消費者向け製品などの業界に変革をもたらした。アクリル樹脂成形は、時間の短縮だけでなく効率も向上させ、公差が厳しく(+-0.1mm)、光学的に透明な(光透過率90%以上)部品を作ることができた。.

アクリル金型の種類

アクリル型にはいくつかの種類があり、それぞれの型は要求される生産性や製品の複雑さに応じて生産されます。適切なタイプを選択することで、アクリル成形における高い品質と効率が保証されます。.

単一キャビティ金型

単一キャビティ金型は、各射出サイクル後に単一の部品を作るために作られます。この金型は、生産量が少ない場合やプロトタイプのプロジェクトで使用することができます。単一キャビティ金型では、アクリル材料の射出成形工程は、誤った成形や曖昧な表面の問題に対処する必要がないように、検討中の用語を使用して行われます。.

マルチキャビティ金型

マルチキャビティ金型は、1サイクルで何個も製造できる。そのため、大量生産に適している。マルチキャビティ金型は、一貫性を保ち、生産時間を最短にするため、アクリルで成形されることが多い。.

ファミリー・モールド

ファミリーモールドは、1つのサイクルでさまざまな部品の一部を生成する。これは、製品アセンブリを構成する部品を成形する際に実用的なタイプです。ファミリーモールドは、アクリル樹脂成形を使用することができ、複数の部品を同時に製造することができるため、時間とコストの両方を節約することができます。.

ホットランナー金型

ホットランナー金型は、プラスチックの無駄を最小限に抑え、効率を向上させるために流路に保つことができます。ホットランナーシステムは、滑らかな表面と欠陥の少ない高精度の製品に適合するアクリル金型を使用しています。.

コールドランナー金型

コールドランナー金型は、成形品と一緒に冷却される流路を採用している。この金型はコストが低く、生産が容易である。中小メーカーの多くは、むしろコールドランナー金型を使ってアクリル成形を行い、安く生産している。.

いわゆるアクリル金型の適切なタイプの選択は、生産量、製品のデザイン、予算によって決定されます。金型の正しい選択は、アクリル射出成形のより良いパフォーマンスと高品質の完成品につながります。.

アクリル樹脂成形の技術

アクリル樹脂成形は、アクリル物質を便利で魅力的なアイテムに変換するためにいくつかの方法を使用するプロセスです。どちらの方法にも強みがあり、デザイン、生産量、製品のニーズによって決まります。.

射出成形

アクリル射出成形と呼ばれる最もポピュラーなものは、アクリルペレットと呼ばれるアクリルのサブユニットを溶けるまで加熱し、アクリル型に射出する。冷却すると、プラスチックは意図した形状に固化する。これは、高精度の製品を大量に作るのに最適な方法です。.

圧縮成形

アクリル板を熱した型に入れ、プレスして成形する圧縮成形。この技法は、厚みのある部分や無地のデザインにも応用できます。アクリルの圧縮成形は、厚みや強度を均一にするために行われます。.

押出

長い連続したプロファイルは、溶融したアクリルを成形ダイに押し込む押出成形によって作られます。押出成形では、チューブ、ロッド、シートなどに使用されます。断面や表面は均一です。.

熱成形

熱成形技術は、アクリル板を柔軟性が出るまで加熱し、真空または圧力をかけて金型上で成形する。このアプローチは、巨大または非巨大な製品でうまく機能します。熱成形は、合理的に低コストでアクリルプラスチック金型の低〜中ボリュームのメーカーの技術です。.

回転成形

回転成形はアクリルでも使われるが、加熱中に型を回転させ、型の内側を均一にコーティングする。くぼみのある形もこの技法で効果的に作ることができる。回転成形では、デザインに合わせてアクリルを成形できる柔軟性があります。.

アクリルの成形工程

アクリルの成形は、原料のアクリルが高品質の完成部品に変化する重要かつ技術的なプロセスです。この工程にはいくつかの工程があり、各工程では温度、圧力、時間を正確にコントロールすることで、アクリル成形に最適な結果をもたらします。.

材料の準備

反応は、さまざまなサイズ(通常は直径2~5mm)のアクリル製の高品質ペレットから始まる。ペレットの含水率は0.2以下であるべきで、それ以上の含水率は成形過程で気泡を発生させる可能性がある。ペレットは通常、使用前に80~90℃のホッパー乾燥機で2~4時間以上乾燥させる。.

溶解と射出

乾燥したペレットは射出成形機のバレルに導入される。バレルの温度は230~280℃に保たれ、アクリルグレードは使用するグレードによって異なる。ペレットはスクリュー機構によって溶融され、溶融状態の均質なアクリル混合物を形成する。.

その後、アクリルは通常70~120MPaの高圧で、一度溶けたアクリル型に射出される。射出時間は部品の大きさによって異なり、小型から中型の部品では約5~20秒かかります。.

冷却

射出後、アクリルが冷えて固化する際に、加圧された金型が置かれる。冷却時間は部品の厚みによって異なる:

- 厚さ1-2mm: 15~20秒

- 厚さ3-5mm: 25~40秒

- 厚さ5mm以上: 45~60秒

冷却は、反り、収縮、表面欠陥をなくすために必要である。確立された金型は、必要な仕様の温度を維持するために、水管や油冷を利用することもある。.

型開きと射出

金型が冷却されると型開きが行われ、機械式または油圧式のエジェクターピンを使って部品が排出される。射出する力は、表面を傷つけたり変形させたりしないように制限する必要がある。.

後処理

部品はまた、排出後の部品の切り落としや研磨、アニールなどの仕上げ工程を経ることもある。80~100℃の温度で1~2時間エージングすることで、内部応力を除去し、透明度と強度を高めることができる。.

品質検査

個々の部品は、気泡、反り、寸法などの欠陥に対してチェックされる。ノギスを利用したり、レーザースキャンを行ったりし、高精度の部品を扱う場合は公差を+0.1mm以内にする。良質のアクリル樹脂成形を採用することで、すべての製品が業界標準となっている。.

プロセスパラメータの概要:

| ステップ | パラメータ | 価値 |

| 乾燥 | 温度 | 80-90°C |

| 乾燥 | 期間 | 2~4時間 |

| バレル温度 | メルト・アクリル | 230-280°C |

| 射出圧力 | 70-120 MPa | |

| 冷却時間 | 厚さ1~2mm | 15~20秒 |

| 冷却時間 | 厚さ3~5mm | 25~40秒 |

| 冷却時間 | >厚さ5mm以上 | 45~60秒 |

| アニーリング | 温度 | 80-100°C |

| アニーリング | 期間 | 1~2時間 |

| 寸法公差 | ±0.1 mm |

アクリル射出成形は、以下のような技術的特徴を持ち、各製品の品質、精度、効率を保証します。アクリル射出成形のプロセスは、部品の一貫生産を確保する最適化された条件を使用することにより、透明で耐久性があり、寸法精度の高い部品を製造するために使用することができます。.

アクリル射出成形の用途

アクリル射出成形は、精度、透明度、寿命が求められる分野で多用されている。.

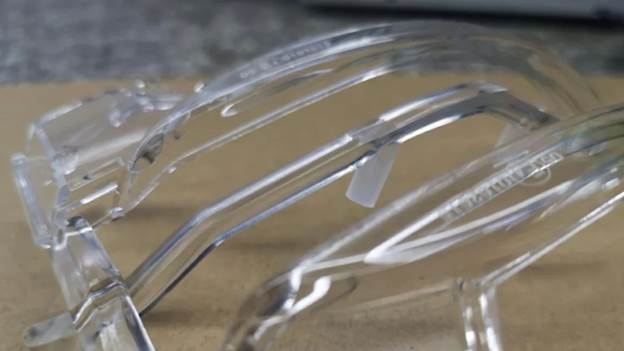

自動車産業

テールライト、ダッシュボード、トリムは、アクリル型から作られる。部品の厚さは通常1.5~5mmで、温度範囲は-40~80℃です。透明度と寿命はアクリル成形によって保証されます。.

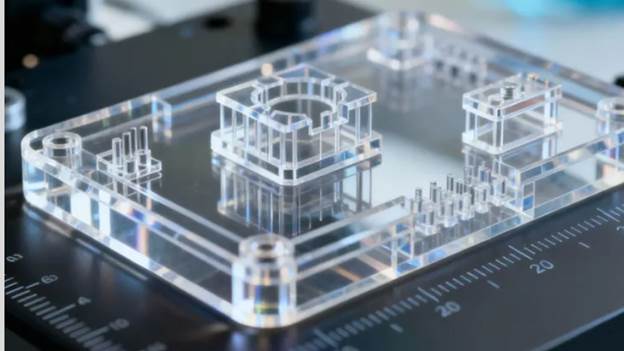

ヘルスケアと医療機器.

実験器具、器具カバー、保護シールドは、アクリルプラスチック成形の工程で製造される。公差+-0.1mm、滅菌可能な部品が要求されます。アクリル射出成形は、滑らかで正しい表面を保証します。.

コンシューマー・エレクトロニクス

スマートフォンカバー、LEDハウジング、保護スクリーンはアクリルで成形される。90%を超える表面光沢と正確な寸法が必要です。.

アンフェタミン、メタンフェタミン、家庭用品や装飾品に含まれるアンフェタミン。.

化粧品容器、陳列ケース、パネルなどの製品は、いわゆるアクリル樹脂成形品を使って製造される。平均的な厚みは2~8mmで、滑らかで透明感のあるカラフルな仕上がりが得られます。.

電気部品、照明、光学部品。.

アクリル射出成形は、LEDレンズ、光拡散板、看板の透明性に使用される。この部品は、特定の角度と厚さで90%を超える光の透過率を達成します。.

産業機器

アクリル成形をベースとしたマシンガード、インストルメントパネル、透明容器の使用がある。部品には15~20kJ/m2の衝撃強度と透明性が要求される。.

代表的なアプリケーション

このフレームワークは、医療サービスの質、コスト、アクセシビリティ、提供されるサービスの量など、医療サービスの主な特徴をすべて政府が管理している場合に適用される。.

産業

- 製品例

- 主な仕様

- 自動車

- テールライト、ダッシュボード

- 厚さ1.5~5 mm、温度40 °C~80 °C

ヘルスケア

- 試験管ラック、シールド

- 公差-0.1mm、耐滅菌性。.

エレクトロニクス

- カバー、ハウジング

- 表面光沢90、寸法安定性。.

消費財

- 化粧品の入った容器、展示用の箱。.

- 厚さ2~8mm、平滑仕上げ

- 照明

- LEDレンズ、ディフューザー

- 透過率90%以上、正確なジオメトリー。.

- インダストリアル

- ガード、コンテナ

- 衝撃強さ15~20 kJ/m 2、透明。.

アクリル成形の品質管理

アクリル成形では、規格に合った部品を作るために品質が不可欠です。ちょっとしたキズが性能や外観に影響することもあります。.

部品の検査

すべての部品は、気泡や曲がり、表面の傷などがないか検査される。公差が+-0.1mmを超えないようにノギスやレーザースキャナーを使って測定する。アクリル射出成形の工程は、高い品質を保証する方法として、定期的な検査に依存しています。.

金型メンテナンス

定期的な清掃と点検を徹底することで、欠陥を防ぎ、金型の寿命を延ばすことができる。古い金型は、寸法の不正確さや表面の凹凸の原因になることがあります。.

プロセス監視

温度、圧力、冷却時間は、アクリル成形の過程で常にチェックされる。バレル温度は平均230~280℃、射出圧力は70~120Mpaで、ミスを防ぐ。.

最終テスト

完全な部品は、機能試験と目視試験によって検査される。例えば、光学部品は光の透過性(90%以上)、構造部品は衝撃強度(15~20kJ/m2)を検査しなければならない。.

これは、最終製品の品質を厳しく管理し、信頼性が高く、正確で、審美的に完璧なアクリル樹脂成形の個々の部品を生成することによって達成することができます。.

適切なアクリル射出成形アライアンスの選択

高品質の生産に関しては、アクリル射出成形のメーカーを正しく選択することが重要である。.

経験と専門知識

アクリル成形とアクリル成型の経験があるパートナーを探しましょう。経験豊富な技術者であれば、金型の設計、射出、仕上げを最大限に仕様に合わせることができるだろう。.

設備と技術

温度(230-280℃)、射出圧力(70-120Mpa)を調整する革新的な機械は、製品の一貫性を高める上で非常に有効です。高品質のアクリル金型と自動化されたシステムにより、エラーや無駄を最小限に抑えることができます。.

品質保証

信頼できるサプライヤーになると、寸法チェック(公差-0.1mm以内)や表面チェックなど、部品の厳しいチェックが行われる。正しいQAにより、アクリル樹脂の部品は透明で耐久性があり、欠陥がないことが保証される。.

コミュニケーションとサポート

優れた製造業者は、設計と製造のプロセスで相互作用します。彼らは金型の最適化、材料の提案、材料のサイクルタイムの最適化を支援します。.

アクリル成形を成功させるための提案

高品質で正確、かつ耐久性のある部品を作るためには、アクリル成形のベストプラクティスに従うことが望ましい。.

高品質の素材を使用する

含水率0.2未満のアクリル2~5mmサイズのペレットから始める。80-90℃で2-4時間乾燥させることで、アクリル成形時の気泡や表面欠陥をなくすことができます。.

金型設計の最適化

適切なベントデザインを作成し、適切な冷却チャネルと射出ポイントを持つアクリル金型を設計します。アクリルの射出成形工程における反り、収縮、サイクルタイムを最小限に抑えます。.

プロセスパラメータの制御

バレル温度は230~280℃、射出圧力は70~120Mpaに保つ。冷却時間は部品厚みと同等にする:

- 1~2mm-15~20秒

- 3~5mm、25~40秒

- 5 mm - 45-60秒

定期的な検査

部品の寸法(寸法の最大誤差0.1mm)、光点、光学的透明度(透過率90%以上)をチェックする。アクリル樹脂成形の利点は、一貫した検査ができることにあります。.

金型のメンテナンス

金型の摩耗を防ぎ、スムーズで安定した生産を保証するために、金型を洗浄・清掃します。成形アクリルは、部品の効率と品質の向上を発見した。.

これらのヒントはすべて、アクリル射出成形のプロセスに、確実で、魅力的で、完璧に正しい部品を毎回提供する。.

蔓延する欠陥と防止策

正確なアクリル射出成形でも不具合は発生する。その原因と解決策を知ることが、アクリル射出成形の品質を保証します。.

気泡

アクリル型内に空気があると、表面に気泡が生じることがある。.

推薦する: アクリルNPの乾燥は水分0.2%以下、金型の正しい換気、射出圧力70~120マッキー。.

ワーピング

部品が均等に冷却されず、歪んでしまうのだ。.

解決: 均質な冷却流路、部品の温度、部品の厚さに応じた部品の冷却時間(例えば、1~2mm-15~20秒、3~5mm-25~40秒)。.

シンクマーク

ヒケは、厚みのある部品が冷却中に収縮する際にできる。.

解決策 アクリル成形の肉厚、充填圧力、適切な冷却速度を最大化する。.

ショートショット

ショートショットは、溶融したアクリルが金型に充填されない場合に発生する。.

解決: 射出プレスの圧力を上げ、アクリル金型の詰まりを取り除き、正しいバレル温度(230~280℃)を確認する。.

表面欠陥

アクリル樹脂成型品にざらつきや傷があると透明度が低下する。.

治療法 金型を磨き、射出力を使いすぎず、加工エリアを清潔に保つ。.

アクリル射出成形の展望

技術、効率、持続可能性がアクリル射出成形の未来である。.

高度なオートメーション

アクリル成形は、自動化、ロボット化が進んでいる。温度(230-280℃)と射出圧力(70-120Mpa)は、機械によって正確に制御することができます。成形によるアクリル製造の自動化は、人的ミスを減らし、サイクルタイムを向上させる。.

3Dプリンティングとプロトタイピング

アクリルのプロトタイプの金型は、限られた時間の中で3Dプリントによって実現される。このため、エンジニアは本格的な生産に入る前に、設計の実験や金型の最適化を行うことができる。アクリル樹脂成形は、迅速なプロトタイピングにより、より速く、より安くなる。.

サステイナブル素材

アクリル廃材をリサイクルし、環境に優しい素材を開発することは当たり前のことになりつつある。射出成形でアクリル製品を製造する際にリサイクルされるペレットは、製品の品質には影響しないものの、環境負荷の低減につながる。.

製品品質の向上

将来的には、アクリル成形と呼ばれるもので、光学的透明度(光透過率90%以上)、表面仕上げ、寸法管理(+-0.1mm)が向上するだろう。これにより製品が強化され、より透明で精密なものになる。.

業界の成長

耐久性があり、軽量で透明な製品へのニーズが高まる中、市場は自動車、医療、電子機器、消費財の分野でアクリル成形の活躍の場を広げていくだろう。.

技術と持続可能性の採用を通じて、アクリル射出成形は高品質で効率的な生産に使用される製造工程のひとつであり続けるだろう。.

Sincere Tech:アクリル射出成形の信頼できるプロバイダーです。.

Sincere Tech(Plas.co)は、精密プラスチック成形とアクリル成形のサービスを提供しています。 射出成形, 信頼できる私達は私達のハイテク技術および熟練労働者によって保証される強く、正確な、魅力的な部品を持っています。私達はあなたの設計指定に従って私達が作る注文仕立てのアクリルの型および解決を取扱います。.

健全で信頼できるソリューション。.

試作・製品設計から大量生産までワンストップで行います。アクリル成形、アクリル成型の経験を生かし、高品質、高耐久性、高信頼性の部品をご提供いたします。.

Sincere Tech(プラス・コー)を選ぶ理由は?

私たちの仕事の例は以下で見ることができる。 https://plas.co. .Sincere Tech(Plas.co)は、品質、精度、サービスにおいて最高のものを求めるお客様のパートナーです。.

結論

アクリル成形とアクリル射出成形は、現在の生産に欠かせない工程である。品質が高く、長持ちし、ファッショナブルな製品を提供する。アクリル金型の設計から始まり、一貫した部品の作成に至るまで、効率的で信頼できるものです。.

メーカーがベストプラクティスを守り、適切なパートナーを選べば、アクリル成形の力を借りて高品質の製品を生産することができる。技術のさらなる成熟は、アクリル射出成形が革新的で、正確で、美的な製品の開発において最も重要なもののひとつになることを意味する。.