Bij de moderne productie staan efficiëntie en precisie voorop. Enkele van de gebruikte technieken zijn gasondersteund spuitgieten. Spuitgieten met behulp van gas is een technologische productiemethode die helpt om lichte, duurzame en complexe kunststofonderdelen te maken. De holle delen worden gemaakt door de matrijs te injecteren met inert gas, wat de hoeveelheid gebruikt materiaal vermindert en ook de cyclustijd verkort.

Het resultaat hiervan is een grotere maatnauwkeurigheid, minder vervormingen en de mogelijkheid om innovatieve ontwerpen uit te voeren. Spuitgieten met gasondersteuning is nuttig in de auto-industrie, de meubelindustrie, de elektronische industrie en de industrie voor consumentenproducten, waar een rendabele productie met een hoge kwaliteit nodig is. Betrouwbare sentinel gas assist injection molding leveranciers zijn verzekerd van een regelmatig resultaat. Met de heersende productie maken de meeste fabrikanten gebruik van spuitgegoten producten die worden geholpen door het gebruik van gas, waardoor fabrikanten efficiëntie, sterkte en esthetiek kunnen bereiken.

Wat is spuitgieten met behulp van gas?

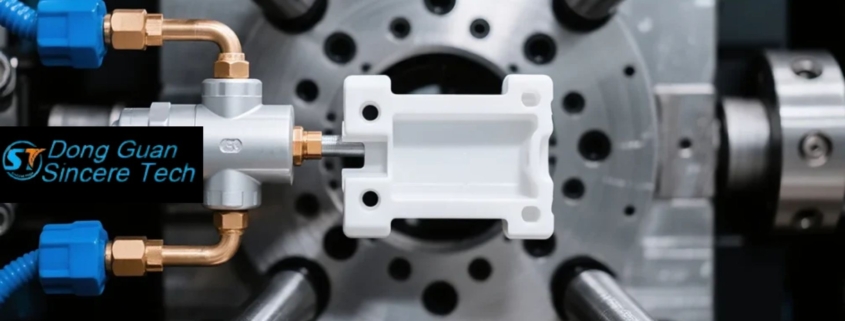

Gasassistent spuitgieten is het proces waarbij inert gas (meestal stikstof) in de matrijs wordt gespoten tijdens het spuitgieten van de kunststof. Het gas duwt de warme kunststof tegen de dunne wanden of holte van het onderdeel, waardoor er een holte in ontstaat. Deze techniek bespaart materiaal, vergroot de nauwkeurigheid van de afmetingen en minimaliseert kromtrekken.

Het proces is het meest geschikt voor dikke secties of secties met lange stromingstrajecten. Het wordt veel gebruikt bij de productie van auto's, meubels en consumentenproducten. De kwaliteit en betrouwbaarheid worden gegarandeerd door de keuze van geschikte leveranciers van gasondersteund spuitgieten.

Werking van gasondersteund spuitgieten

Het begint net als het conventionele spuitgieten, waarbij kunststof in een mal wordt gespoten. Zodra de matrijsholte gedeeltelijk gevuld is, wordt er gas onder druk geïnjecteerd in sommige gebieden. Dit gas zorgt ervoor dat de vloeibare kunststof naar buiten wordt gedrukt om holle kanalen te vormen, ls maar maakt het oppervlak hard.

De methode resulteert in minder spanning in dikkere onderdelen, nulverzakkingen en een uniforme wanddikte. Het resultaat is een onderdeel van hoge kwaliteit dat vormstabieler, lichter en sterker is. Dit zijn eigenschappen die functioneel en esthetisch zijn voor de fabrikanten van producten zoals spuitgieten met gasondersteuning.

Toepassingen van spuitgieten met gasondersteuning: Spuitgieten met behulp van gas is een buigzame productietechniek die wordt omarmd in de belangrijkste industrieën. Holle of ingewikkelde vormen kunnen met minder moeite worden gemaakt, waardoor het geschikt is voor zowel nuttige als decoratieve doeleinden.

Autofabrikanten spuitgieten met behulp van gas interieurpanelen, deurgrepen en structurele onderdelen. De procedure maakt ze licht zonder de sterkte te verliezen die gekoppeld is aan brandstofefficiëntie en prestaties.

Meubels en consumentenproducten

Het gasondersteunde spuitgieten wordt gebruikt om holle secties te maken in kunststof onderdelen van meubels, apparaten en gereedschappen. De lichte onderdelen zoals stoelruggen, handgrepen en behuizingen vormen een efficiënte productiemethode.

Industriële apparatuur

Voor robots en machines zijn meestal sterke kunststofonderdelen van een bepaalde grootte nodig. Producten die gemaakt worden op basis van spuitgieten met gasondersteuning zijn duurzaam, hebben een standaard wanddikte en zijn bestand tegen kromtrekken.

Elektronica Gasondersteund spuitgieten wordt gebruikt bij de productie van consumentenelektronica, gereedschapsbehuizingen en andere apparaten die er sterk en aantrekkelijk uit moeten zien, met een laag materiaalverbruik.

Andere toepassingen

Het wordt ook gebruikt in sportuitrusting, speelgoed en verpakkingen. De fabrikanten nemen hun toevlucht tot de diensten van de gas-assisted spuitgietleveranciers die de mogelijkheid hebben om onderdelen van de gegeven grootte en kwaliteit te produceren.

Bedrijven die dergelijke toepassingen kennen, kunnen het volledige voordeel van spuitgieten met behulp van gas ervaren om lichtgewicht en betaalbare producten te maken.

Gebruikt materiaal

Thermoplasten: Thermoplasten zijn de meest gebruikte materialen bij spuitgieten met gasondersteuning. Sommige materialen kunnen gemakkelijk worden bewerkt en gebonden in het gasgestuurde proces, zoals polypropyleen (PP), polyethyleen (PE), ABS en polycarbonaat (PC). Deze kunststoffen zijn geschikt voor de productie van lichte en sterke spuitgietproducten.

Versterkt plastic: Met glas versterkte kunststoffen van nylon of polypropyleen zijn extra taai en stijf. Ze worden gebruikt op plaatsen waar het onderdeel wordt blootgesteld aan een hoge mate van spanning of belasting en zullen het dus goed doen bij de auto- of industriële onderdelen die worden geproduceerd tijdens gasondersteund spuitgieten.

Speciale polymeren: In sommige gevallen worden speciale polymeren gebruikt die worden gekenmerkt door een hoge hittebestendigheid of chemische weerstand. Deze materialen bepalen de vereisten van het product in specifieke termen die de prestaties en levensduur garanderen. Het gebruik van gasondersteund spuitgieten, dat al eerder in de industrie is toegepast, helpt bij de keuze van het juiste materiaal voor elke toepassing.

Materiaalkeuze: Het gebruikte medium moet uitstekende vloei-eigenschappen, thermische stabiliteit en gasinjectiecompatibiliteit hebben. De juiste materiaalselectie is heel belangrijk voor het verminderen van defecten, sterkte en efficiëntie van de onderdelen die gebruikt worden in het proces van spuitgieten met gasinjectie.

Technieken

Wederzijdse injectie met behulp van gaskanalen

Hierbij worden holle onderdelen gemaakt door ze op sommige plaatsen in de mal te pompen. Dit bespaart materiaal en zorgt voor uniformiteit in de dikte van de wanden. Het wordt ook veel gebruikt bij de productie van lichtgewicht en taaie composieten met behulp van spuitgieten.

Aanpasbare gasdrukregelaar

De druk van het gas kan tijdens het vormen ook worden aangepast om de stroming van het materiaal beter te manipuleren. Dit voorkomt zinkvlekken, verbetert de oppervlakteafwerking en maakt de kunst sterker. En het belangrijkste is dat gevallen van gasondersteund gieten van hoge kwaliteit spuitgegoten producten.

Sequentiële gasinjectie

Sequentiële gasinjectie houdt in dat er gas wordt geïnjecteerd in verschillende stadia van het spuitgietproces. Deze procedure garandeert de optimalisatie van de materiaalstroom in de vorm van een volledige X-vorm en de vermindering van het aantal defecten. De leveranciers moeten ook benaderd worden omdat ze bekend zijn met gasondersteund spuitgieten, zodat het nauwkeurig kan gebeuren.

Geavanceerde koelmethoden

Gasondersteund gieten met geavanceerde koelsystemen is handig om onderdelen snel te laten stollen en de cyclustijd te verkorten. Dit bevordert de productiviteit en belemmert het ontwerp van het onderdeel niet.

Voordelen van gasondersteund spuitgieten

Als we het traditionele spuitgieten vergelijken met het zogenaamde gasondersteunde spuitgieten, kunnen we verschillende voordelen opmerken:

Materiaalbesparingen

De holle profielen verbruiken ook minder plastic en verlagen zowel de kosten als de impact op het milieu.

Minder kromtrekken en zinkplekken

Gasondersteund gieten minimaliseert de meeste veelvoorkomende defecten, zoals verzakkingen of oppervlaktevervormingen door de gelijkmatige verdeling van het materiaal.

Aansteker Onderdelen

Er zijn holle structuren beschikbaar waarmee lichte onderdelen kunnen worden gemaakt zonder dat dit ten koste gaat van de sterkte.

Snellere productie

Geassocieerd met minder materiaalverbruik en een betere doorstroming is een verkorting van de cyclustijden; iets wat acceptabeler is voor de fabrikanten.

Verbeterd ontwerp speelruimte

Het is mogelijk om complexe vormen te maken en dikkere onderdelen toe te voegen zonder de kwaliteit te verminderen of het duur te maken.

Ontwerpoverwegingen

Ondersteund spuitgieten met gas moet ook goed gepland worden om het proces te maximaliseren.

Materiaalselectie Alle kunststoffen kunnen met gasgespoten worden. De ontwerpers moeten materialen gebruiken die gemakkelijk vloeien en hechten onder gasinjectie.

Wanddikte

De muren moeten even dik zijn. De open ruimtes moeten op strategische plekken worden geplaatst om kracht en functionaliteit te creëren.

Plaatsing van het gaskanaal: De locatie van het gaskanaal is het belangrijkst. Als ze op de verkeerde plaats worden aangebracht, kunnen ze halfgevulde vullingen, zwakke punten of esthetische defecten achterlaten.

Vormontwerp

Kunststof en gasvormige doorgangen moeten mogelijk zijn naar de mallen. De poorten moeten goed geventileerd en ontworpen zijn om ervoor te zorgen dat de productie effectief verloopt en defecten tot een minimum beperkt blijven.

Deze ontwerpspecificaties zorgen voor een hoge kwaliteit en betrouwbaarheid bij het spuitgieten met behulp van gas.

Kosten en productie-efficiëntie

Kosten en productie-efficiëntie gasondersteund spuitgieten is zeer economisch in vergelijking met de traditionele processen op het gebied van matrijzen, de kosten en de snelheid waarmee de producten worden geproduceerd. Het bespaart op de materiaalkosten omdat de onderdelen holle ruimtes zijn die goed en zuinig zijn.

Het proces zorgt ervoor dat gesmolten kunststof vrij kan stromen en dit bespaart tijd bij het koelen. Hierdoor kunnen de fabrikanten de onderdelen sneller produceren zonder dat dit ten koste gaat van de kwaliteit. Bedrijven die de artikelen produceren met behulp van gasgestuurde spuitgietproducten hebben het voordeel dat ze sneller zijn en dat de resultaten consistent zijn.

De samenwerking met de experts die het gasgestuurde spuitgietproces leveren, vermindert het aantal handmatige handelingen en het verzamelen, waardoor ook de arbeidskosten dalen. Dit is zeer efficiënt in termen van materiaalbesparing, minder cycli en defecten, ook al zijn de matrijzen in het begin ingewikkelder.

Veelvoorkomende fouten die je moet vermijden

Bij spuitgieten met gasondersteuning worden verschillende fouten gemaakt die de kwaliteit en de efficiëntie van het product kunnen verstoren. Een verkeerde gasdruk is een veel voorkomend probleem. Een te hoge of te lage druk kan leiden tot vervorming van onderdelen of defecten.

Een andere fout is een slechte kanalisatie van gassen. Elke verkeerde uitlijning kan leiden tot gedeeltelijke vulling of gladde wanden die producten gevuld met gasondersteund spuitgieten zwak maken.

Het probleem van de verkeerde combinatie van gebruikte materialen komt ook vaak voor. Sommige kunststoffen reageren niet goed op gasondersteunde processen, wat leidt tot defecten of slechte hechting.

Het negeren van ontwerprichtlijnen, zoals wanddikte en geometrie van het onderdeel, kan ook problemen opleveren. Onderdelen kunnen verbuigen, verzakken of onder spanning komen te staan.

De volgende fouten kunnen geëlimineerd worden door samen te werken met ervaren leveranciers van spuitgieten met gasondersteuning, door de juiste ontwerp- en procesrichtlijnen in acht te nemen en door een constante productie van hoge kwaliteit te garanderen.

Het identificeren van de juiste leveranciers van injectie spuitgieten met gasondersteuning

Succesvol spuitgieten met behulp van gas hangt af van de keuze van de juiste partner. Samenwerken met gerenommeerde leveranciers garandeert kwaliteitsonderdelen en ononderbroken productieprocessen.

Selecteer de gasondersteuning spuitgieten leveranciers die een succesvol verhaal hebben in de productie van spuitgietproducten met gasondersteuning van dezelfde aard, vergelijkbaar met jouw project. Ze kunnen defecten voorkomen en hun efficiëntie verbeteren met behulp van hun ervaring in het ontwerp van de matrijzen en de selectie van het gebruikte materiaal.

De leverancier moet ook een procesoptimalisatiegids leveren voor het proces, zoals gasdruk, positioneerkanalen en cyclustijden. Dit kan worden toegepast om verspilling en onnauwkeurigheden in de productie te verminderen.

Kwaliteitsleveranciers investeren in kwaliteitscontrolesystemen en nieuwe apparatuur. Ze zorgen voor betrouwbare resultaten, een hogere snelheid en kostenefficiëntie in spuitgietprogramma's met gasondersteuning.

Toekomstige trends

Het is de toekomst van spuitgieten met gasondersteuning, die afhangt van innovaties en efficiëntie. Fabrikanten kijken naar nieuwere, sterkere, lichtere en duurzamere materialen. Dit zijn technologieën die resulteren in hoogwaardige spuitgietproducten met gasondersteuning.

De andere belangrijke trend is automatisering. De robots en AI-systemen nemen steeds vaker de gasinjectie en de matrijsbehandeling voor hun rekening, en ze maken een einde aan de fouten en zorgen ervoor dat het productieproces sneller verloopt. De gasleveranciers met ervaring in spuitgieten omarmen de technologieën ook om de concurrentie bij te benen.

Ook duurzaamheid krijgt aandacht. Het gebruik van minder materialen, plastic recycling en energiebesparende productie zijn milieuvriendelijke productie-elementen in de productie van milieuvriendelijk spuitgieten, ook wel gasondersteunend spuitgieten genoemd.

Dit wordt versterkt door de toevoeging van 3D-printen, dat de mogelijkheden van snelle prototyping en serieproductie uitbreidt. Dit helpt ontwerpers om te experimenteren met complexe vormen tegen lage kosten en binnen de kortst mogelijke tijd; op deze manier is gasondersteund spuitgieten productiever in de moderne productie.

Conclusie

Gasondersteuning spuitgieten kan fabrikanten een haalbare aanpak bieden voor het produceren van lichtgewicht, gecompliceerde en robuuste componenten. De bedrijven zijn in staat om de juiste beslissing te nemen, omdat ze weten hoe het werkt, wat de voordelen zijn en op welke manier het ontworpen moet worden. De keuze voor betrouwbare leveranciers van spuitgietproducten met gasondersteuning zou betekenen dat de standaard van spuitgietproducten met gasondersteuning in alle bedrijfstakken hetzelfde zou zijn. De afname van de hoeveelheid gebruikt materiaal resulteert in een toename van de productiesnelheid en de mogelijkheid om wijzigingen aan te brengen in ontwerpen, wat de populariteit verhoogt van de techniek die een vrij noodzakelijke vorm van moderne productie wordt.