Moldagem por injeção de metal: um guia para uma nova revolução na fabricação

O aumento da fabricação fez com que a moldagem por injeção de metal se tornasse uma das tecnologias mais influentes. Os processos de modernização nos setores, como o processo de moldagem por injeção MIM, atualmente dependem do processo, enquanto a eficiência global está crescendo com o uso das soluções chinesas de moldagem por injeção de metal. Essas ferramentas, como os sistemas de molde de injeção de metal, são muito eficazes na produção de um projeto preciso, e novos métodos de produção, como a moldagem por injeção de metal, permitem a produção de componentes metálicos potentes, complicados e confiáveis. O mais importante é que a invenção da técnica de moldagem por injeção de metal mudou o potencial industrial a ponto de, atualmente, as empresas terem adquirido novos padrões de eficiência e qualidade.

O que é moldagem por injeção de metal?

Moldagem por injeção de metal A moldagem por injeção de metal (MIM), também conhecida como moldagem por injeção de metal, é um processo inovador de fabricação que combina a precisão da moldagem por injeção de materiais plásticos com a resistência e a estabilidade dos metais. Ele permite a fabricação de componentes metálicos complexos, pequenos e muito precisos que, de outra forma, seriam difíceis ou antieconômicos de serem produzidos por processos de usinagem convencionais.

A tecnologia surgiu como a base da fabricação moderna, especialmente em setores como aeroespacial, automotivo, dispositivos médicos, eletrônicos e defesa. A moldagem por injeção MIM permite que os fabricantes formem formas complexas, minimizem o desperdício de materiais e garantam resultados finais de alta qualidade.

Principais características da moldagem por injeção de metal

- Geometria complexa: Capaz de produzir peças de formas que não seriam produzidas por meio de usinagem convencional.

- Alta precisão: Mantém padrões rigorosos dos principais constituintes.

- Eficiência do material: A sucata e os resíduos são minimizados em comparação com a metalurgia tradicional.

- Escalabilidade: Ele pode suportar a prototipagem de pequenos lotes e a produção de grandes volumes.

- Custo-benefício: Reduz a mão de obra necessária e os processos secundários, e fabrica peças que duram.

Moldagem por injeção de metal em ascensão na China

Moldagem por injeção de metal da China A China tem sido um dos líderes mundiais na produção de peças metálicas de precisão nos últimos anos. Os fabricantes chineses são agora um destino favorável para empresas de todo o mundo que precisam de um componente de metal acessível, mas de qualidade, devido à sua tecnologia avançada, engenheiros qualificados e capacidade de produção competitiva.

O surgimento da moldagem por injeção de metal na China é um indicador de um avanço tecnológico e do investimento de longo prazo nas atuais instalações de produção. A China investiu em suas capacidades de moldagem por injeção de MIM e, juntamente com a fabricação em escala, conseguiu fortalecer seu domínio nos setores automotivo, aeroespacial, eletrônico, de equipamentos médicos e de defesa.

Fatores importantes para o desenvolvimento da moldagem por injeção de metal na China

Tecnologia avançada

O Fabricantes chineses estão usando os melhores equipamentos e linhas de produção automatizadas, o que garante a precisão e a consistência de todas as peças fabricadas.

Mão de obra qualificada

O envolvimento de grupos de engenheiros e técnicos com experiência de longo prazo no campo do desenvolvimento de moldagem por injeção de metal contribui para a otimização da produção e dos níveis de alta qualidade.

Competitividade de custos

O custo de produção na China é relativamente barato e, portanto, a moldagem por injeção de metal da China pode ser considerada uma alternativa viável para empresas que precisam cortar custos sem afetar a qualidade.

Escalabilidade rápida

As instalações chinesas são capazes de gerenciar a prototipagem em pequena escala, bem como a produção em grande escala e, portanto, são um bom parceiro para as indústrias globais.

Padrões globais de qualidade

As empresas contemporâneas de moldagem por injeção de metal na China estão em conformidade com os padrões internacionais, como ISO e RoHS, e é por isso que a produção é confiável e certificada.

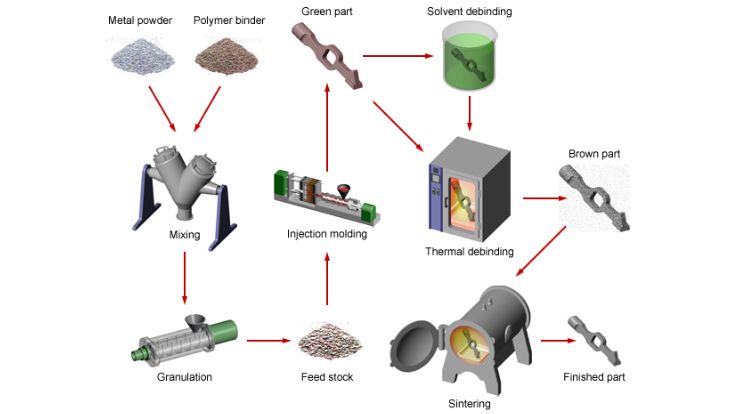

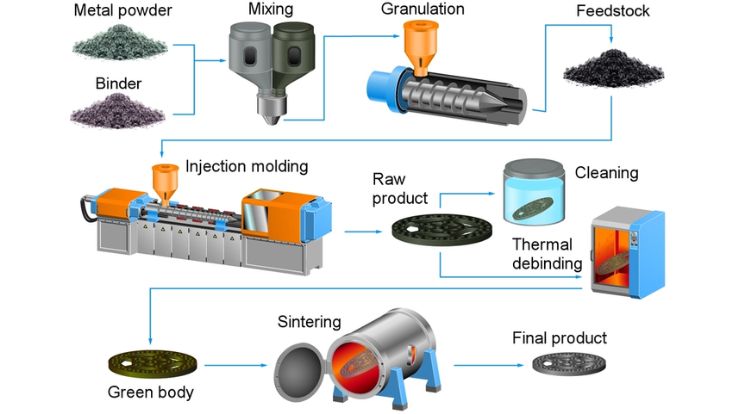

Processo de moldagem por injeção de metal?

A moldagem por injeção de metal é um processo de produção complexo que oferece a flexibilidade da moldagem por injeção de plástico com a potência e a longevidade do metal. Ela permite que os fabricantes produzam peças de metal minúsculas, complicadas e extremamente precisas que são difíceis ou caras de serem produzidas em usinagem convencional.

Em sua forma mais básica, o processo se baseia no trabalho com pós metálicos finos, aglutinantes e moldes para fins especiais. A moldagem por injeção MIM permite que os engenheiros fabriquem peças altamente complexas e de grande volume com facilidade e ainda tenham tolerâncias e desempenho mecânico bons e estreitos.

Etapa 1: Preparação da matéria-prima

O estágio inicial é a preparação da matéria-prima, que é uma mistura de pós metálicos finos e aglutinante de polímero. É um aglutinante que ajuda no fluxo do pó metálico no processo de injeção e no formato da peça até que ela seja sinterizada.

Pontos principais:

- O tamanho e a distribuição do pó metálico são muito importantes para a qualidade da peça final.

- A seleção de aglutinantes afeta as propriedades de fluxo e a desbobinagem.

- A mistura homogênea é usada para obter densidade e resistência uniformes em cada peça.

Para obter sucesso na moldagem por injeção de metal, é necessário preparar adequadamente a matéria-prima para garantir que todas as peças sejam fabricadas para atender aos requisitos rigorosos em termos de dimensões e características.

Etapa 2: Moldagem por injeção

A matéria-prima pronta é injetada no chamado molde de injeção de metal, e o formato e as características da peça são determinados. O projeto do molde é muito importante para garantir a alta precisão e a prevenção de defeitos.

Os benefícios da moldagem por injeção no MIM:

- Proporciona algumas das geometrias mais complicadas com o mínimo de usinagem secundária.

- Garante alta precisão com grandes quantidades de produção.

- Minimiza o desperdício em comparação com os métodos convencionais de usinagem.

É nesse ponto que a peça moldada é conhecida como peça verde, que tem o aglutinante, mas não é suficientemente densa. Os fabricantes podem produzir peças com designs complexos e tolerâncias muito estreitas que, de outra forma, seriam difíceis com outras técnicas de produção usando a moldagem por injeção MIM.

Etapa 3: Desbobinamento

A remoção do aglutinante deve ser feita após a moldagem, e isso é conhecido como desbobinamento. Isso pode ser feito por meio de:

- Desbobinamento térmico: O aquecimento do componente vaporiza o aglutinante.

- Desbobinamento com solvente: Aglutinante que é dissolvido em uma solução química.

- Desbobinamento catalítico: Um catalisador é usado para desbastar em baixas temperaturas.

O desbaste eficaz faz com que o componente não rache ou se deforme, o que é essencial para preservar a precisão no processo de moldagem por injeção de metal.

Etapa 4: Sinterização

O componente desbastado é sinterizado em temperaturas elevadas que são inferiores à temperatura de fusão do metal. Durante a sinterização:

- As partículas de metais se fundem para formar massas que se tornam mais fortes.

- Há um pequeno encolhimento, e isso é levado em consideração durante o projeto do molde.

- São obtidas as propriedades mecânicas finais, que incluem dureza e resistência à tração.

A sinterização é a mudança na peça, que antes era uma peça verde fraca, mas agora é uma peça completa de alta resistência. Essa etapa é essencial para garantir a confiabilidade e a durabilidade dos produtos fabricados com a ajuda da moldagem por injeção de metal.

Etapa 5: Pós-processamento e controle de qualidade.

Após a sinterização, as peças podem aderir a outros processos, como:

- Acabamento de superfície (polimento, revestimento ou galvanização).

- Garantia de melhores qualidades por meio de aquecimento.

- Verificação para verificar se ele atende aos requisitos do projeto.

O controle de qualidade garante que os componentes de moldagem por injeção de metal tenham um padrão industrial e sejam confiáveis em seu uso selecionado.

Características de um excelente molde de injeção de metal

Precisão dimensional

Uma moldagem por injeção de metal de qualidade garantirá a precisão nas dimensões e tolerâncias uniformes de todos os componentes produzidos pela moldagem por injeção de metal. A precisão minimiza a usinagem secundária e é importante para setores como o aeroespacial, o automotivo e o de dispositivos médicos.

Durabilidade

Os moldes duráveis são fabricados com materiais resistentes ao desgaste e capazes de suportar todos os ciclos de alta pressão e temperatura. Os moldes duráveis são usados na moldagem por injeção de metal da China para garantir a eficiência da produção e a mesma qualidade das peças.

Gerenciamento térmico

O controle térmico adequado evita o empenamento e o resfriamento uniforme no processo de moldagem por injeção do MIM. Isso garantirá uma densidade, resistência e acabamento uniformes em cada componente.

Facilidade de manutenção

Os moldes modernos são fáceis de manter, com peças substituíveis que minimizam o tempo de inatividade e aumentam seus ciclos de vida. A produção de moldagem por injeção de metal é suave e confiável devido à manutenção eficiente.

Geometria complexa

Moldes excelentes podem criar formas complexas com paredes finas e recursos finos. Isso possibilitou a capacidade da moldagem por injeção de metal de produzir peças que não poderiam ser produzidas de outra forma usando meios de produção comuns.

Potência e inovação da moldagem por injeção de metal

Força tecnológica

A moldagem por injeção de metal é um processo de engenharia e fabricação sofisticado e de alta precisão que permite aos setores fabricar peças pequenas, complicadas e de alta resistência de forma econômica. A força dessa tecnologia reside no fato de que ela combina a flexibilidade do design da moldagem por injeção de plástico com a resistência mecânica do metal, o que antes era impossível de ser obtido por meio de abordagens tradicionais. As empresas que aplicam o conceito de moldagem por injeção MIM desfrutam das vantagens de ciclos de produção mais rápidos, a qualidade dos produtos é sempre mantida e as empresas podem ser inovadoras ao projetar produtos.

Aplicativos do setor

Ela pode ser usada em diversos setores devido ao uso inovador da moldagem por injeção de metal, e isso pode ser encontrado nos setores automotivo, aeroespacial, de dispositivos médicos, de eletrônicos de consumo e de defesa. Ao utilizar as vantagens da moldagem por injeção de metal chinesa, as empresas estão em condições de utilizar a acessibilidade das soluções sem afetar o desempenho, produzindo componentes de alto padrão no setor.

Material na moldagem por injeção de metal

Pós metálicos

Os pós metálicos finos são os principais componentes em um processo de moldagem por injeção de metal que determinam a resistência, a durabilidade e as propriedades de composição dos produtos finais. O aço inoxidável, o titânio, as ligas de níquel e o cobre são os pós comumente usados. O pó usado determina a dureza, a corrosão e o desempenho de estresse. São necessários pós de alta qualidade para garantir que a moldagem por injeção MIM produza peças homogêneas, com altas qualidades mecânicas e com bom desempenho quando submetidas a tarefas exigentes.

Materiais de encadernação

Outro ingrediente importante da matéria-prima para moldagem por injeção de metal são os aglutinantes. Eles são propofol e incham como adesivos temporários quando injetados e moldados para unir os pós metálicos. Os aglutinantes são então removidos com muito cuidado nos processos de desbobinamento após a moldagem. A escolha do aglutinante a ser usado será decisiva para o fluxo suave durante o processo de moldagem, a precisão nas dimensões e um produto final impecável. A remoção do aglutinante é um dos processos mais importantes para uma produção eficaz no processo de moldagem por injeção de metal.

Materiais compostos e especiais

Materiais compostos ou misturas de metal-cerâmica podem ser utilizados em aplicações mais avançadas. Esses são os materiais especiais que permitem que os fabricantes, inclusive os envolvidos na prática de moldagem por injeção de metal em porcelana, façam os componentes com uma característica específica, como alta resistência ao calor, design leve ou aumento da resistência mecânica. Com a seleção e a combinação minuciosas desses materiais, é possível atender às demandas exigentes de setores como aeroespacial, dispositivos médicos, eletrônicos e defesa com a ajuda da moldagem por injeção de metal.

Seleção do material a ser usado

Os materiais usados no processo de moldagem por injeção de metal têm um efeito direto no resultado final da potência mecânica da peça, no acabamento e na estabilidade térmica da peça. Os engenheiros precisam levar em consideração elementos como tamanho e distribuição das partículas, compatibilidade com o aglutinante e propriedades de sinterização para maximizar a produção. A escolha correta dos materiais significa que as peças que estão sendo produzidas por meio da moldagem por injeção MIM não são apenas funcionais, mas também confiáveis e duráveis na esfera em que serão usadas.

Potencial futuro

O desenvolvimento contínuo de materiais, o desenvolvimento de moldes e os processos de sinterização garantem que a moldagem por injeção de metal seja uma das tecnologias mais populares de fabricação de precisão aceitável. Os engenheiros agora podem fabricar componentes com propriedades mecânicas aprimoradas, menor peso e maior durabilidade. O desenvolvimento contínuo do conceito de moldagem por injeção de metal oferece perspectivas ainda maiores de avanço tecnológico no design industrial, na eficiência da produção e no desempenho dos produtos.

Moldagem por injeção de metal: Quando é necessário?

No caso de peças complexas e precisas

O uso da moldagem por injeção de metal é necessário pelo fato de que as indústrias precisam de componentes metálicos muito complexos, detalhados e em miniatura, que são feitos de forma ineficiente usando técnicas convencionais de usinagem e fundição. Com a ajuda da chamada moldagem por injeção MIM, os fabricantes poderão obter detalhes finos, paredes finas e formas detalhadas, preservando a resistência e a precisão.

Onde a resistência e a durabilidade são de grande importância

Isso é necessário nos casos em que os componentes precisam ser resistentes a alta pressão, calor e estresse mecânico. Os produtos fabricados com o uso de moldagem por injeção de metal são muito resistentes, usáveis e confiáveis e, portanto, têm aplicação em setores industriais como o automotivo, o aeronáutico e o de defesa.

Quando é necessário um grande volume de produção

A moldagem por injeção de metal é recomendada caso as empresas precisem de produção em massa de seus produtos com qualidade constante. A moldagem por injeção de metal na China é aplicável em muitos setores para realizar uma produção eficiente, de alto volume e econômica, sem redução da precisão dimensional.

Sempre que a relação custo-benefício for importante

Nos casos em que se prefere minimizar o desperdício de materiais, o tempo de mão de obra e o processamento secundário, a moldagem por injeção metálica será a escolha. Ela tem alta eficiência de produção e, ao mesmo tempo, é de alta qualidade, sendo, portanto, uma das soluções de fabricação mais econômicas.

Quais materiais são aceitáveis na moldagem por injeção de metal?

A moldagem por injeção de metal favorece os materiais de alto desempenho. Os mais comuns são o aço inoxidável, o aço para ferramentas, o titânio, as ligas de níquel, o cobre e as ligas magnéticas. Todos os materiais são escolhidos de acordo com a propriedade necessária, que pode ser resistência, dureza, resistência à corrosão, resistência ao calor e durabilidade. Isso criou flexibilidade no MIM para atender a demandas intensivas nos setores automotivo, médico, aeroespacial, eletrônico e de engenharia industrial.

Aço inoxidável

O material mais comum usado na moldagem por injeção de metal é o aço inoxidável. Ele é altamente resistente à corrosão, forte e durável e, portanto, pode ser usado em equipamentos médicos, equipamentos de processamento de alimentos, peças automotivas e produtos de consumo. Classes como 316L e 17-4PH são populares por causa de suas excelentes qualidades mecânicas e confiabilidade.

Aço para ferramentas

O aço ferramenta é escolhido sempre que os componentes exigem extrema dureza, resistência ao desgaste e tenacidade. Ele pode ser aplicado em ferramentas de corte, componentes de máquinas industriais, engrenagens e elementos estruturais de alta tensão/abrasão. O aço ferramenta garante um longo ciclo de vida e alta estabilidade dimensional em situações de estresse.

Titânio

O titânio é um metal muito valorizado na moldagem por injeção, com peso leve e alta resistência. Ele também oferece excelente resistência à corrosão e biocompatibilidade e, mais uma vez, é um material perfeito para uso em componentes aeroespaciais, peças de engenharia de alto desempenho e implantes médicos, como dispositivos ortopédicos e odontológicos.

Ligas de níquel

As ligas de níquel são aplicadas nos casos em que o componente precisa ser resistente a altas temperaturas, corrosão e condições severas de trabalho. Elas oferecem estabilidade térmica superior e resistência à oxidação, o que as torna ideais para componentes aeroespaciais, equipamentos de processamento químico e montagens mecânicas de alta temperatura.

Cobre

Na moldagem por injeção de metal, a moldagem por injeção de metal envolve o uso de cobre, que exige altos níveis de condutividade elétrica e térmica. Normalmente, ele é encontrado em peças eletrônicas, peças de dissipação de calor, conectores e hardware elétrico. O cobre também é um bom material resistente à corrosão e é ideal quando é necessária uma engenharia elétrica de precisão.

Ligas magnéticas

Os componentes que precisam de altas propriedades magnéticas são feitos com ligas magnéticas, como os aços inoxidáveis magnéticos macios e as ligas que contêm ferro. Elas encontram ampla aplicação em sensores, motores, dispositivos eletrônicos, sistemas automotivos e em aplicações elétricas de precisão. Elas proporcionam um alto nível de desempenho magnético e resistência mecânica.

Usos da moldagem por injeção de metal

Setor automotivo

A moldagem por injeção de metal também é um processo importante no setor automotivo, na medida em que fabrica peças altamente resistentes e precisas, como engrenagens, suportes, peças de motor e dispositivos do sistema de segurança. Os fabricantes podem criar formas complexas, que não seriam economicamente viáveis por meio da usinagem convencional, com a ajuda da moldagem por injeção MIM. Os recursos da moldagem por injeção de metal da China também são essenciais para muitas empresas produzirem em grandes quantidades sem sacrificar a qualidade.

Medicina e saúde

O setor médico se beneficiou muito com o uso da moldagem por injeção de metal, pois ela é capaz de fabricar peças pequenas, precisas e biocompatíveis. A moldagem por injeção de metal é usada para fabricar instrumentos cirúrgicos, braquetes ortodônticos, implantes ortopédicos e carcaças de dispositivos. Alguns dos materiais suportados pelo processo incluem aço inoxidável e titânio, tornando-o muito durável e eficaz no uso médico, onde é altamente necessário.

Aeroespacial e Defesa

A confiabilidade e o desempenho são fundamentais no mundo aeroespacial e de defesa. Componentes leves, mas de alta resistência, como peças de turbina, acessórios estruturais, componentes de armas e conectores de precisão, são comumente produzidos por meio de moldagem por injeção de metal. Ao usar a moldagem por injeção MIM, os setores podem ter alta precisão dimensional, resistência e consistência, que são essenciais em um ambiente de alto risco.

Eletrônicos de consumo

A moldagem por injeção de metal é aplicada na indústria eletrônica para produzir peças muito pequenas e detalhadas, como conectores, dobradiças, componentes de telefone e componentes de hardware. A precisão da moldagem por injeção MIM e a eficácia da moldagem por injeção de metal da China são um impulso favorável à produção em massa de peças eletrônicas altamente duráveis, suaves e leves.

Construção de máquinas e ferramentas industriais.

O maquinário industrial e as ferramentas de engenharia também dependem do uso da moldagem por injeção de metal para a fabricação de componentes resistentes ao desgaste. Parte das ferramentas de corte, travas, fixadores e montagens mecânicas geralmente são fabricadas com o uso de moldagem por injeção de metal. Isso permite que os setores tenham desempenho, resistência e permaneçam eficientes em uso mesmo em condições adversas.

Vantagens industriais da moldagem por injeção de metal

Eficiência de custo

A moldagem por injeção de metal é muito econômica. Os fabricantes podem usar peças complexas com um mínimo de materiais residuais (usando a moldagem por injeção MIM) e baixos custos de mão de obra. As empresas que dependem da moldagem por injeção de metal da China conseguem obter componentes de qualidade a um baixo custo.

Precisão e complexidade

O processo permite a fabricação de peças complexas e de alta precisão que, de outra forma, seriam difíceis ou impossíveis de serem fabricadas por meio de técnicas tradicionais. Recursos completos, pequenas tolerâncias e novos projetos contam com o apoio da moldagem por injeção de metal, que é adequada para aplicações aeroespaciais, médicas e automotivas.

Consistência e confiabilidade.

Nos processos de produção controlados, há a chamada moldagem por injeção de metal, que faz com que cada peça atenda a requisitos rigorosos. O uso da moldagem por injeção MIM e das instalações de moldagem por injeção de metal na China oferece uma produção regular e confiável, que minimiza erros e retrabalho.

Versatilidade

Os componentes de vários setores, como equipamentos médicos, eletrônicos e de defesa, podem ser produzidos por meio do processo de moldagem por injeção de metal. Ele é flexível e, portanto, os fabricantes podem responder com eficácia às necessidades dinâmicas do mercado.

Sustentabilidade

Ela minimiza a quantidade de resíduos de materiais e energia consumidos no processo e, portanto, a moldagem por injeção de metal é um processo de fabricação ecologicamente correto. A moldagem por injeção MIM incentiva a fabricação sustentável sem redução da qualidade.

Sobre o Dong Guan Sincere Tech

A Dong Guan Sincere Tech é um fabricante chinês de manufatura de precisão que lida com moldagem por injeção de metal (MIM) e soluções sofisticadas de engenharia. Com anos de experiência no ramo, além de contar com a mais recente tecnologia e uma equipe de técnicos muito profissional, podemos nos orgulhar de estarmos entre os melhores e mais confiáveis fabricantes de moldagem de metal da China.

Oferecemos serviços completos, como moldagem por injeção MIM, soluções de moldagem por injeção de metal na China, projeto de moldes de injeção de metal, desenvolvimento de peças personalizadas e fabricação de componentes de alta precisão para os setores automotivo, médico, aeroespacial, eletrônico e industrial. Nossas fábricas atuais, o gerenciamento da qualidade e a adesão à inovação garantem que tudo o que produzimos excederá os padrões de qualidade, durabilidade e precisão exigidos e requeridos pelas normas internacionais.

Em Dong Guan Sincere Tech, nosso lema é fornecer a melhor qualidade a custos razoáveis e prestar excelentes serviços aos nossos clientes, o que nos torna uma opção confiável para clientes de todo o mundo. Caso precise dos melhores serviços de moldagem por injeção de metal na China, então você encontrou a melhor empresa em que pode confiar para oferecer o melhor.

Considerações finais

A moldagem por injeção de metais não é uma técnica, mas uma revolução na engenharia de precisão. O mundo agora é mais inovador, eficiente e confiável por meio dos desenvolvimentos da moldagem por injeção MIM, da precisão de cada molde de injeção de metal, do poder de desempenho da moldagem por injeção de metal, bem como o avanço tecnológico da moldagem por injeção de METAL. O caminho dessa tecnologia continua a se desenvolver, e há muito mais reservado que pode trazer mais oportunidades para o futuro da produção industrial.

O que é moldagem por injeção de metal (MIM)?

A moldagem por injeção de metal é um processo sofisticado de fabricação que envolve o uso de pó metálico e material aglutinante para formar componentes metálicos complexos e de alta resistência. Ele permite a criação de peças detalhadas, precisas e resistentes que não podem ser facilmente criadas usando a usinagem tradicional.

Quais setores podem receber o Metal Injection Molding?

A moldagem por injeção de metal tem ampla aplicação em aplicações automotivas, aeroespaciais, de equipamentos médicos, eletrônicos e de defesa, bem como em equipamentos industriais. Ela seria perfeita para a fabricação de componentes pequenos, complexos e altamente precisos que precisam ter um alto nível de resistência e desempenho.

Quais são os motivos pelos quais a Dong Guan Sincere Tech deve ser selecionada para fornecer serviços MIM?

A Dong Guan Sincere Tech é um dos principais e mais conceituados fabricantes de moldagem por injeção de metal da China. Projetamos e fabricamos produção de alta qualidade, tecnologia, controle de qualidade, preços competitivos e suporte profissional de engenheiros para obter resultados de alta qualidade em qualquer projeto.

Você tem condições de atender a grandes volumes de produção?

Sim, também produzimos tanto em pequenos lotes quanto em grandes escalas. Temos instalações modernas e uma equipe altamente qualificada que nos permite oferecer altos níveis de consistência e eficiência em projetos de produção em massa e, ao mesmo tempo, manter a precisão e a confiabilidade.

Quais são os materiais da moldagem por injeção de metal?

É usada uma variedade muito grande de materiais, como aço inoxidável, titânio, ligas de níquel e metais de desempenho especial. Para garantir o bom desempenho de um produto, cada material é escolhido em termos de força, durabilidade, resistência à corrosão e uso.

Deixe uma resposta

Quer participar da discussão?Sinta-se à vontade para contribuir!