Clear Plastic Injection Molding and Its Applications

The global injection-molded plastic market is rapidly expanding. According to a study, the market was worth USD 387.51 billion in 2023. It is predicted to increase to USD 561.58 billion by 2032. Clear injection molding is a process for producing transparent plastic objects. So we will shed light on the process and advantages of clear plastic injection molding in detail.

What is Clear Plastic Injection Molding?

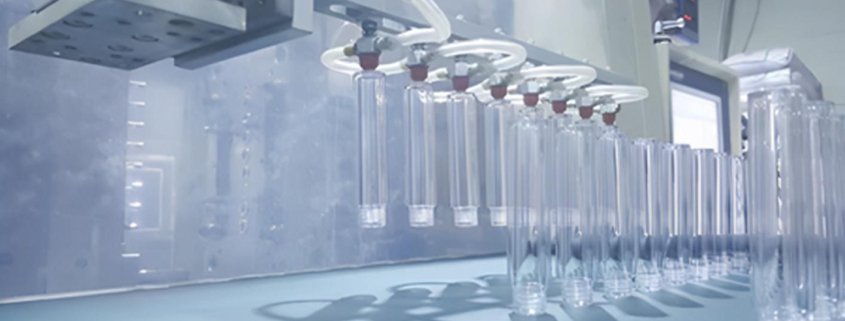

We use many transparent plastic products in our daily lives. These products are lenses, windows helmets, etc. Have you ever wondered how these products are formed? They are performed using a different procedure known as clear injection molding. Different materials are used in this process, such as polycarbonate, polymethyl methacrylate, and high-density polyethylene. You can choose any material that meets the user’s demands. As a result, this process requires careful material selection and specific types of equipment. Furthermore, temperature control is necessary to ensure that products have minimal flaws.

Commonly Used Materials in Clear Plastic Injection Molding:

Different types of materials are used in clear injection molding. Let’s talk about some of the most used materials.

1. Acrylic(PMMA)

Acrylic is another name for polymethyl methacrylate. It is a non-toxic material. It is UV-resistant. Furthermore, it has excellent light transmittance. It has the disadvantage that it is brittle. But we can polish it to lessen the brittleness. Lear more about PMMA injection molding.

2. PolyCarbonate

Polycarbonate is a heat-resistant material. This property makes it ideal for use in heat shields. It is also used to manufacture safety goggles. Moreover, the material is also clear and transparent. But it is a bit of a costly material. Learn more about Polycarbonate injection molding.

3. High-Density Polyethylene

High pressure and high temperatures convert petroleum into high-density polyethylene. It can easily be converted into different shapes. It is used for the mass production of containers and pipes. It is not a toxic material. So it can also manufacture food storage containers.

Step-by-Step Process of Clear Plastic Injection Molding:

Now you have adequate information about injection molding. So let’s discuss the complete step-by-step procedure in detail.

1. Mold Design

The very first stage is to create a mold that is based on the desired plastic part shape and size. So, first, we’ll specify the geometry of the mold, which includes cavities, cores, and runners. The most commonly used materials may include steel and aluminum. On the other hand, processes such as casting, machining, or 3D printing can make the mold. We can also use computer-aided design (CAD) software to design a fully aligned mold.

2. Material Selection

We use different materials in injection molding according to our requirements. Consider properties like strength, flexibility, and melting point before choosing the plastic material. You can purchase the plastic pellets or granules from the supplier. If necessary, you can include additives or colorants in the material. Make sure to dry that material to remove any moisture. You can use a dryer to minimize the moisture content. Drying the material is essential to avoid cracks and small bubbles. This prevents defects in the final parts.

3. Machine Selection

Now you are done with material selection. So, the next step is to choose an injection molding machine. Select the machine according to the part’s size and material. Set up the mold in the machine’s clamp unit. Connect the machine’s hydraulic and electrical systems. You can also set the machine’s temperature and pressure according to your needs.

4. Injecting the Material

Put the plastic material into the machine’s hopper. After that, heat the substance until it melts. Typically, we heat the material using the machine’s barrel and screw. Use the nozzle and runner system to inject molten plastic into the mold cavity. The plastic is injected at a high pressure of around 500–1500 psi. It moves through the runners before entering the mold cavity. As the screw revolves, the plastic material spreads. Plastic melts and mixes under extreme temperatures and pressure. Make sure the mold is filled. This avoids flaws and provides the plastic with uniform qualities.

5. Cooling the Plastic

The molding machines have cooling channels that contain water and oil. They aid in cooling the plastic material within the mold and have a typical cooling time of 10–60 seconds. Besides this, time depends on the material and thickness of the plastic. Proper cooling ensures a uniform plastic structure.

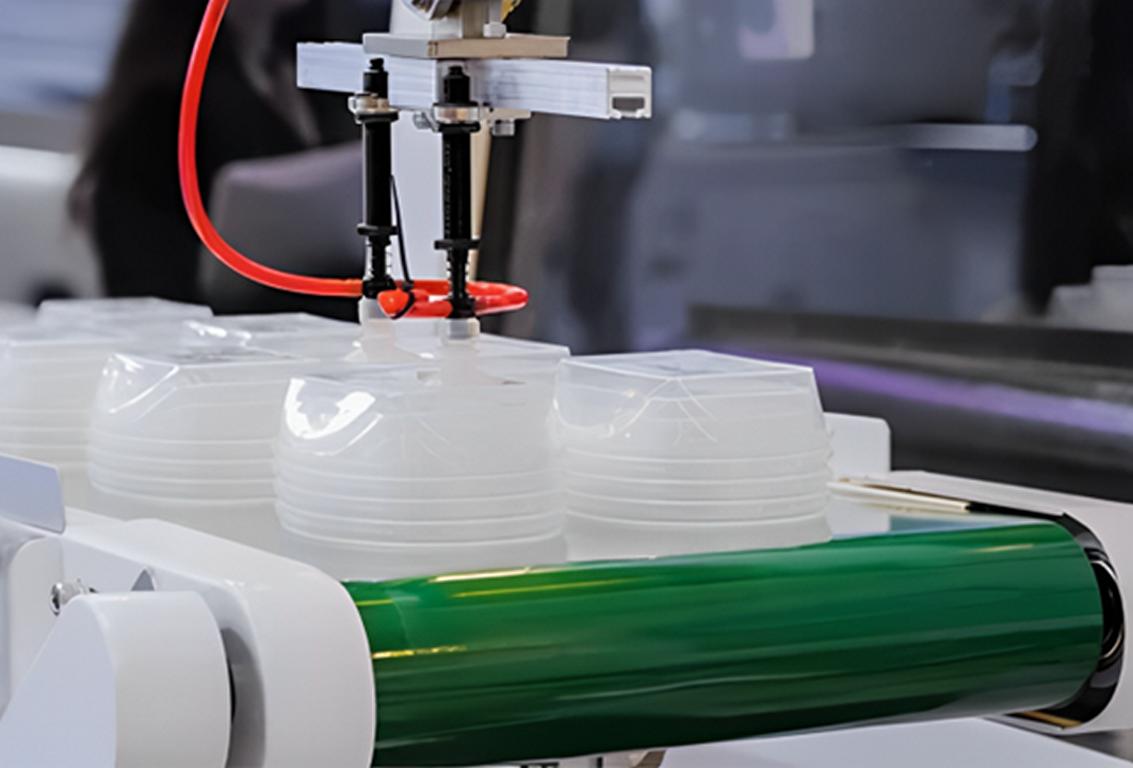

6. Ejecting the Plastic

Finally, the plastic material is cooled. So now you can eject it. Ejector pins force the finished plastic out of the mold as the mold opens. After that, we place the mold on a conveyor belt or storage area.

7. Trimming

We use trimming tools to remove the excess plastic from the finished material. Clean the prepared plastic by using solvents. After that, we dry it with methods like blowing. We then check the part for quality issues. Parts undergo physical and mechanical checks to assure dimensional accuracy. Now it is ready to ship to customers.

Common Defects of Clear Plastic Injection Molding

Here is a brief table for the clear injection molding defects

|

Defect |

Causes |

Potential Solutions |

|

Flow Lines |

Inconsistent flow of molten plastic, mold temperature too low, injection speed too fast |

Increase mold temperature, adjust injection speed, optimize gate location, and design |

|

Weld Lines (Knit Lines) |

The confluence of melt fronts during injection, insufficient pressure, or temperature |

Increase injection pressure, raise mold temperature, and modify part design to minimize weld line occurrence |

|

Sinks (Sink Marks) |

Differential cooling rates and inadequate packing pressure |

Increase packing pressure and time, modify gate location and size, and design thicker cross-sections in critical areas |

|

Bubbles (Air Traps) |

Air entrapment during molding and inadequate venting |

Improve mold venting, optimize injection parameters, and use materials with better flow properties |

|

Cloudiness or Haze |

Poor material drying or contamination, inconsistent melt temperature |

Ensure proper material handling and drying, maintain consistent melt temperature, and use optical-grade materials if required |

|

Streaks or Scratches |

Mold or tooling imperfections, contaminants, or debris in the mold cavity |

Clean and polish molds regularly, inspect and maintain tooling, and use appropriate mold release agents |

|

Warpage |

Non-uniform cooling or shrinkage, improper ejection |

Optimize cooling channels, use uniform wall thickness, adjust ejection parameters and sequence |

|

Dimensional Variations |

Inconsistent cooling rates, improper mold design or maintenance |

Ensure uniform mold temperature, control processing parameters tightly, and regularly inspect and maintain molds |

Advantages of Plastic Injection Molding

Now you are familiar with the complete procedure of the injection molding process. So let’s explain the advantages of this process. Here are a few of its advantages:

1. Accurate Shape

Clear injection molding creates parts with exact shapes and sizes. Moreover, the parts produced are resistant to chemicals and scratches. Additionally, the plastic parts are transparent and clear. So plastic is used in appliances where visibility is important.

2. Cost Effective

It is a budget-friendly process. It produces large plastic parts at an affordable price. So it is an attractive option for people looking for startups and small businesses

3. Low Maintenance

The plastic produced by the injection molding process requires low maintenance. As mentioned above, it produces clear plastics. The clear plastics are lighter than other materials. They are easy to clean, too. Furthermore, clear plastics are good insulators. So, they are suitable for electrical appliances.

4. Wide Range of Material Selection

Plastic injection molding is quite good at handling various materials with different properties. These may include thermoplastics, elastomers, and thermosets. Besides this, it is versatile and allows manufacturers to select materials according to their requirements, i.e. strength, flexibility, heat resistance, and more.

5. Minimal Material Waste and Environmental Impact

This process helps produce minimal scrap material. Its excess plastic can often be reground and then recycled. Modern methods also focus on demand-reducing energy consumption. Besides this, they also work on reducing emissions during production so this process can become a more environmentally friendly option.

Disadvantages of Plastic Injection Molding:

Plastic injection Molding also has some drawbacks. Let’s discuss them here.

1. High Initial Tooling and Equipment Costs

Initial tooling and equipment costs are high for this process as compared to other products. Mold making is the most expensive part of injection molding, where the designer has to spend a lot of money on the first time designing and manufacturing molds and tools. This cost can sometimes be expensive, particularly when there are only a few products to be produced or when there is unused space in the containers.

2. Design Limitations

However, like any type of manufacturing process, injection molding does have limitations on the designs that the mold can produce. For instance, thin walls may be desirable when there is a need to maintain a uniform wall. It will allow a smooth flow of the molten material all around and avoid the formation of defects. When the part geometries are small and intricate, there could also be more undercuts or small detail features in the mold to capture. It adds to its complication and cost.

3. Lead Time for Tooling

The process of design and construction of these forms is usually lengthy, and such a form may take weeks or even months, depending on the intricacy and measure of the form. It may also reduce product customization, response timing to market trends, and overall lead time to the start of production.

4. Material Limitations and Compatibility

The use of injection molding provides a substrate for a large number of material types. However, every material type has its characteristics and deficiencies. The general fabrication of the material may entail several risks, such as warping and degradation, or require special conditions for processing. Selecting the right type of material is very important and influences the production cost and effectiveness.

5. Quality Control Challenges

The quality of the product has to be controlled at the same level throughout the whole process. You can achieve this by controlling parameters like temperature, pressure, and the cooling rate of the material. When there is a change in these parameters, there can be problems such as sink marks, warping, or problems regarding dimensionality.

Challenges of Clear Plastic Injection Mold

As we all know, every process has benefits and challenges. So, let’s talk about its drawbacks

- Flow Lines: Molten plastic moves at different speeds in the mold. So the resin thickens at different rates. As a result, visible lines appear on the surface of a molded part. Their appearance indicates that the injection speed or pressure is low.

- Weld Lines: Weld lines are also known as knit lines. It occurs when two flow fronts merge. It occurs due to an interruption of plastic flow. They mostly occur around holes. Weld lines are more apparent than flow lines.

- Twists in Finished Plastic: Plastic warping means bends and curves that appear in finished plastics. They occur due to improper mold cooling. We can minimize these twists by providing proper cooling time.

- Delamination of Surface: Sometimes, the surface layer is separate from the underlying layers. It occurs due to excessive injection speed or pressure. Contamination and moisture on the mold surface are another cause of delamination. The surface may become rough and blistered due to delamination.

- Sink Marks: The plastic material may shrink as it cools. It occurs because the outer, thicker portion takes a longer time to cool. so the inner portion may contract. As a result, depressions on the finished plastic surface appear. These are called sink marks. They can be minimized by providing adequate cooling time.

- Maintaining Clarity: An optimum temperature is required for clear plastic formation. The extreme temperature may result in discoloration. So, high temperatures induce stress. As a result, it hinders the transparency of the plastic.

Applications of Clear Plastic Injection Molding

Clear Plastic Injection The molding process has many applications. It manufactures clear plastic cups, plates, bowls, and containers. Hence, it plays a role in the food and beverage industry. Similarly, it also makes plastic chairs and ornaments. Additionally, it plays a role in automotive components and electronic components. It is also used in medical devices and consumer goods.

Conclusion

To sum up, clear plastic injection molding creates high-quality plastic. These raw materials may include acrylics, polypropylenes, and polycarbonates. The process consists of choosing the material and injecting it into the machine. After that, the material is injected into the machine. It is ejected after attaining the required shape. Acquiring accurate shape and cost-effectiveness are its major benefits. It also has drawbacks like weld lines and flow lines. Furthermore, it is used in medical, automotive, electronic, and other industries.

Frequently Asked Questions:

Which material is best for clear plastic injection molding?

Different materials are used for clear plastic injection molding. However, acrylic and polycarbonate are mostly used. These substances are resistant to acids and alkalis. So, they are ideal materials for clear plastic molding.

What are the most common issues associated with clear injection plastic mold?

Clear injection-molded plastic has various challenges. Some of them are flow lines, silver lines, and sink lines. Surface delamination, Plastic warping, and thickness stability are also included

What is the average price of a plastic injection mold?

The average cost of clear injection molding ranges from $100 to $1000. It depends on numerous factors. Some key factors are its raw material, desired design, and the complexity of the mold.