Injection molding tool is one of the most significant aspects of present-day manufacturing of a wide range of plastic parts. Besides this, it has several applications on the market. These products can range from car parts to domestic utensils and so on. This article will help you provide a more detailed analysis of injection molding tools. We will focus on different categories, those currently on the market, and the leading manufacturers.

What is injection molding tooling?

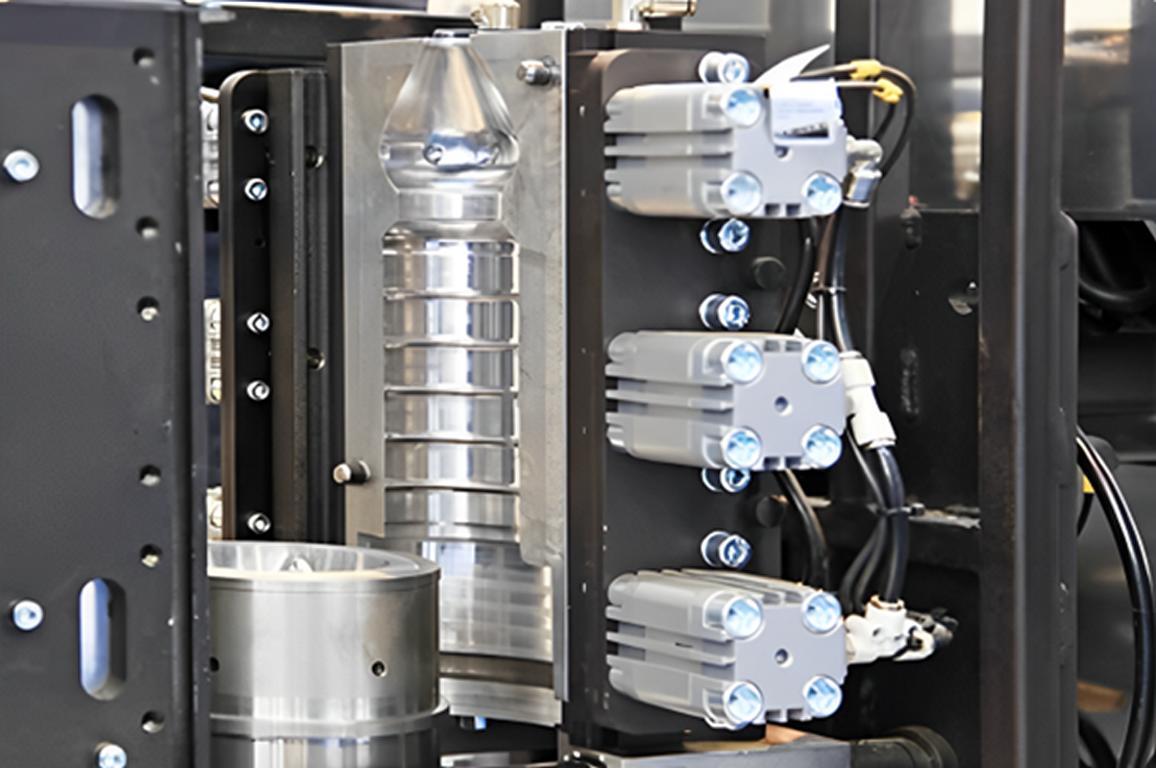

Injection molding tooling can be defined as the equipment and tools that are used in the injection molding process. So, it can help shape molten plastic into finished parts. Besides this, this process is very important in mass-producing complex plastic items, and it offers high precision and efficiency. This may include molding the plastic using a variety of component designs. Moreover, the injection molding tooling setup consists of a mold base, its core, cooling channels, and a cavity plate. So, this whole setup assures that the molten plastic will accurately shape, then cool and eject from the mold.

How are injection molding tools made? A Complete Process

Here is a proper, detailed process for how injection molding tools form.

1. Design Phase

● Conceptual Design: It starts with the engineers and designers making the conceptual mold design according to the product specification. These specs can be part geometry, flow media, or cool media.

● CAD Modeling: Then the CAD tool is employed to build a precise 3D model of the mold that has to be produced. Major components include the component layout, the drafting, the gating, and the cooling system.

● Design Review: Once it is done and reviewed, it is again checked to guarantee that it serves functional and manufacturing requirements. So, this may consist of a prediction of how metal flows within a mold, how the mold cools, or where and how parts are ejected.

2. Prototyping

Here, the prototype mold is often made using a less expensive material, aluminum. This prototype mold is generally used to test the design and confirm the functionality of the mold. So, this step usually helps identify potential issues and make adjustments before final production.

3. Tooling Manufacturing

● Material Selection: Once you finalize the design and its specifications, the next step is selecting the appropriate tooling material. So, the common materials may include tool steel (such as P20, H13), stainless steel, or aluminum. Their selection depends on factors like production volume, part complexity, and cost considerations.

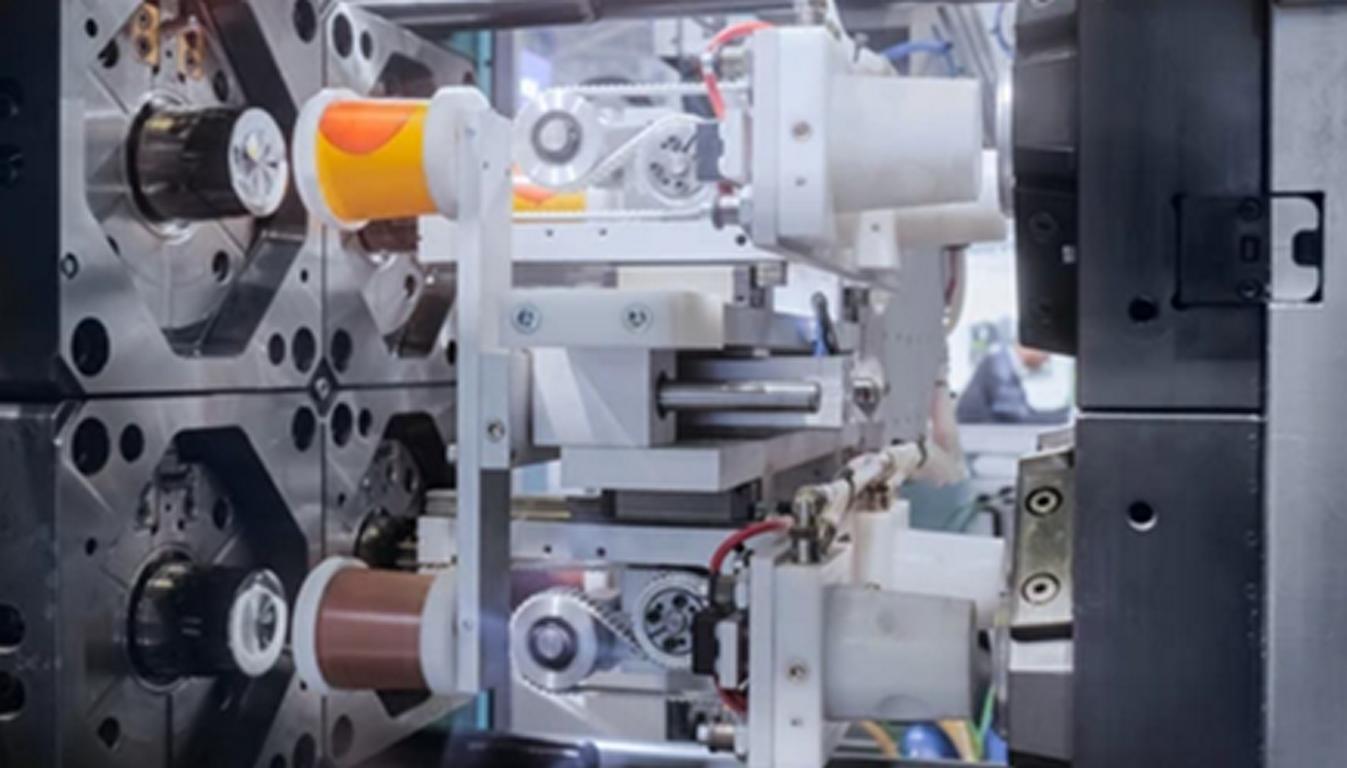

● Machining: CNC machining processes are then used to cut and shape the molded components from the selected material. These processes are usually milling, drilling, and precision grinding. So, they can achieve the required dimensions and surface finishes.

● Heat Treatment: After that, some tooling materials pass through heat treatment processes, i.e., hardening and tempering. They help optimize their mechanical properties, like hardness and toughness.

4. Assembly

● Mold Base: Just after manufacturing, the mold base, cavity, and other components are assembled. So, it primarily includes mounting inserts, slides, and any necessary mechanisms to carry out part ejection and cooling processes.

● Fitting and Alignment: Here, the components are carefully fitted and aligned. So, they can help carry out precise operations during injection molding.

5. Surface Treatment

Here, the critical surfaces of the mold, i.e., the cavity and core, pass through surface finishing processes. So, they can get the required smoothness and texture. So, this may include polishing, EDM (Electrical Discharge Machining), or texturing processes. These all help impart specific surface characteristics to the molded parts.

6. Testing and Validation

● Trial Runs: Once the mold is prepared completely, it experiences the trial runs. These are done using the target injection molding machine and material under production conditions. So, this phase proves mold functionality, part quality, and performance.

● Adjustments: If there is any issue with mold or surfacing, necessary adjustments can be made to cooling, gating, or ejection systems. So, they can help optimize part quality and cycle times.

Types of Injection Molding Tools

Let’s take a look at the different types of injection molding tools available.

1. Single Cavity Molds

Single-cavity molds can form one part at a time in a single shot. These molds are used when there is short-run production or when there is a need to produce prototyping parts. Due to their basic structure, single-cavity molds are comparatively cheaper and easier to construct than multi-cavity molds. Still, they work slowly because they create the part only once, in a single cycle. They are typically used where there is a need for tight tolerance or where the part may have a designation that is difficult to create in a multi-cavity mold.

2. Multi-Cavity Molds

Multi-cavity molds have multiple cavities within the same mold that provide various identical parts in each injection cycle. So, it helps increase production efficiency and also makes multi-cavity molds suitable for high-volume manufacturing. Besides this, these molds are more complex and expensive to make and design as compared to single-cavity molds. However, they help increase production and reduce per-part costs. So, it can justify the initial investment when it comes to mass production scenarios.

3. Family Molds

Family molds create several cavities that produce a variety of parts at the same time in one cycle. This means that each cavity of the mold forms a part, and this may be ideal for assembly environments where numerous parts are most often needed all at once. Family molds are often used for molding parts belonging to a specific group. Because they enable the simultaneous molding of members of this group, which reduces time. However, they must be very well designed in terms of filling and cooling time for all cavities in the mold. This condition can make them more difficult to produce and sustain than single- or multiple-cavity molds.

4. Two-Shot Molds

Two-shot molds or multi-material or multi-colored molds, let two different materials or colors be molded in one cycle. This technique is best for many cases, like gears requiring the incorporation of various colors or materials. So, they can come up with parts with handles or multi-hued areas. The process involves two separate injection cycles: the first material is injected, then it is partially cooled. Secondly, the material is injected over or around the first material. The function and appearance of the parts can be improved through the two-shot molding method. However, this process demands exclusive equipment and accurate designs of the molds.

5. Hot Runner Molds

These molds use a heating system so they can keep the plastic in a molten state as it flows through the runner system to the mold cavities. This approach of as-cast copying diminishes the magnitude of plastic scrap as there are no longer runners to be unfastened and recycled. Hot-runner systems can reduce cycle times and enhance the quality of the part as they help maintain the continuity of the molten plastic, thereby improving the poor surface finish warrants. Cold-runner systems are easier to design than hot-runner molds, but the latter is relatively expensive in both design and manufacturing and in maintenance as well.

6. Cold Runner Molds

Cold-runner molds have channels through which plastic melt flows before it gets into the cavities. Cold runner systems, in contrast, have the runner blocks solidify with the part and need to be removed and frequently recycled or dispensed with. These molds are generally easier and cheaper than hot-runner molds. Therefore, they are suitable for widespread use. Thus, they produce more scrap and the cycle time may be longer because of the necessity to remelt and handle the solidified runners.

Different key parameters and values associated with injection molding tooling

Here are certain key parameters and values that are generally associated with injection molding tooling.

Parameter | Description | Typical Values/Ranges |

Tooling Material | The material used to construct the mold | Steel, Aluminum, and Copper |

Cavity Count | Number of cavities in the mold | Single, Multi (2-16+ cavities) |

Cycle Time | Time for one injection cycle | 10-60 seconds |

Clamping Force | Force to keep the mold closed | 50-4,000+ tons |

Injection Pressure | Pressure to inject plastic | 10,000-30,000 psi |

Cooling Time | Time for the part to cool | 5-30 seconds |

Ejection System | Mechanism to eject part | Ejector pins, stripper plates, and air |

Runner System | Methods of delivering plastic | Hot runner, Cold runner |

Gate Type | The entry point of plastic into the mold | Direct, Pin, Submarine, and Edge |

Surface Finish | Quality of part surface | SPI grades (A1, A2, B1, B2, C1, C2) |

Tolerances | Dimensional deviations | ±0.001-0.005 inches |

Mold Life | Lifespan of the mold | 100,000-1,000,000+ cycles |

Lead Time for Tooling | Time to design and manufacture mold | 4-16 weeks |

Tool Maintenance | Maintenance frequency | Regular cleaning and inspection |

Material Compatibility | Types of plastics used | Thermoplastics, Thermosets, and Elastomers |

Cooling System | Methods to cool mold and parts | Water channels, Conformal cooling |

Part Complexity | The detail level of the molded part | From simple to highly complex |

Shrinkage Rate | Part shrinkage upon cooling | 0.1-2.5% |

Mold Cost | The initial cost to design and manufacture the mold | $5,000-$100,000+ |

What are the Advantages of Injection Mold Tooling?

● High Efficiency: It can, however, be noted that once the molds have been designed and constructed, the actual process of injecting the material into the mold is highly efficient, resulting in the creation of many parts within a short span.

● Consistency and Precision: Injection molding also results in an accurate and even mold release, thus providing similar tolerances for the large run of the same part.

● Complex Geometries: The process enables the designers to come up with multifaceted and elaborate designs on the parts. Something that would not be possible with other techniques.

● Molds, Variety: Both thermoplastic and thermosetting polymers, as well as elastomers, are preferred as most of the materials. Because they exhibit flexibility in their selection.

● Low Waste: Injection molding is eco-friendly today, mainly due to the hot runner systems. Besides this, it does not allow material waste.

● Strength and Durability: It enables the incorporation of the fillers in the injected material to improve the strength and endurance of the parts.

● Automation: Injection molding can involve a high level of automation; this tends to have an impact on lowering labor expenses as well as increasing productivity.

What are the disadvantages of injection mold tooling?

Here are some drawbacks and limitations of injection mold tooling.

● High Initial Tooling Cost: Mold creation and development involve a lot of costs since the designs could be complex, often leading to very high costs.

● Long Lead Times: From design to production, it may take a long time; that is, truth be told, time-consuming where projects with tight schedules are concerned.

● Design Limitations: Changing molds is costly, and at times, it calls for getting new molds altogether.

● Machine; it has constraints: It is not possible to use all the materials when it comes to injection molding, which narrows down the type of material to be used.

● Part Size Limitations: Production is constrained by the size of the mold and the machine; it is difficult for large parts.

● Complex Maintenance: On the other hand, molds need periodic maintenance so they can guarantee productivity and durability.

● Quality Control Challenges: It can be challenging to maintain, especially with the many production runs in the current world markets.

● Environmental Impact: As a manufacturing process, injection molding can produce plastics and hence create plastic waste, hence requiring waste disposal measures.

Conclusion

In conclusion, injection molding tools have a very significant place in modern manufacturing. It provides versatility and efficiency in producing plastic parts. So, it is very important to understand the different types of tools and the factors in choosing the right manufacturer. Besides this, quality and precision, customer support, cost, and turnaround time are also very important considerations when selecting a manufacturer. Additionally, this field of injection molding is continuously evolving and achieving optimal performance and sustainability in manufacturing operations.

Frequently Asked Questions

Q1. How long does it take to manufacture injection molding tooling?

Lead time is the time taken to manufacture the product. So, this can take a few weeks to several months, depending on the design complexity. Besides this, it can change over time.

Q2. What factors should be considered when choosing a tooling manufacturer?

This factor can be experience, quality, customer service, price, time, and the ability to process certain materials. Besides this, intricate parts should also be taken into consideration.

Q3. What are common issues in injection molding tooling?

Such problems include part defects, i.e., warping or sink marks, quality variations, and the localization’s requirement for stringent control of injection factors.