The Swedish manufacturing industry is best known for being innovative, precise, and sustainable, and it is well-developed in Sweden. Injection molding also serves the interest of this sector through the availability of many facets of plastic products used across many industries such as automotive, medical, electronics, and consumer. Currently, the injection molding industry in Sweden is favorably affected by the nation’s power in engineering, advanced technology, and environmentally friendly development. These assist companies in Sweden in sustaining their competitiveness in renderings of the worldwide market with high-quality production. Unfortunately, the injection molding method is extremely flexible and effective in generating simple to complex plastic parts in mass at high quality.

Swedish companies involved in injection molding have procured a strategic market for high-precision components throughout the world, locally as well as in the global market. The success factors for Swedish companies in injection molding include innovation, automation, and material sophistication in delivering solution-based injection molding for client-specific applications. Moreover, many of these companies have adopted corporate environmentalism, recycling plastics, and other technological advancements in producing green products to meet the green shift. Sweden’s highest players in injection molding have embraced adopting modern technology through robotics, digitalization, and automation, which have enhanced production. These firms also strive to provide solutions-based services like designing, prototype development, tooling, and after-sales service.

Below is a list of the five leading injection molding companies in Sweden based on their innovation, experience, and competence as manufacturers of quality, environmentally friendly products. The following companies have worked hard and deserve to be in this industry. This also shows their strict compliance with manufacturing industries while displaying new trends in the molding of plastics.

1. AMB Industry AB

Year of establishment: 1946

Number of employees: 200-250

Business type: As a leading packaging materials supply company, AMB Dairy is experienced in offering proficient and enduring packaging materials intended for the food and medical industries.

Website and Contact

Website: https://amb.se/

Email: info@amb.se

Phone: +46 471 485 00

Address: Kvarnvägen 26, Broakulla, Sweden

Company Profile

AMB Industry AB was founded in the 1950s and is a Sweden-based company specializing in injection molding and surface treatment of high-performance plastics for medical technology applications. An innovative company, it has expanded from its core business of designing and manufacturing medical instruments to various services, including tool designing, tool manufacturing, tool assembling, and tool sterile packing. These enhancements made in the recent past comprise a 5,500 sq.m expansion and a solar park that generates 2 GWh per year—certified to ISO 13485:2016 standards present AMB to function in MedTech, Electronics, and Industrial industries. Ambient provides learning through such programs as the AMB Academy and stresses innovation, making it among the industry’s best companies.

Services

- Project management

- Design & construction

- Mold filling simulation

- Tool making

- Quality assurance

- Validation & documentation

- Measurement and testing

- Packaging & logistics

Pros

1. Sustainability Focus – AMB helps clients understand the necessity of green and recyclable packaging materials – the circle economy.

2. Sectorial specialization – Deals with food and medical packing, hence meeting high requirements fundamental to the sectors.

3. New Concept & Development and Design and Production – Provides concepts and designs along with state-of-art manufacturing technologies to create quality packaging solutions.

Cons

1. Industry-based – Mainly developed for food and medical businesses, which may not be comfortable for other enterprises.

2. Grab and Go Approach – The sustainability initiative’s ability depends greatly on the working of the recycling systems.

3. Cost implication–Using high-quality, durable materials and eco-friendly activities is costlier than standard packaging mechanisms.

Contact AMB Industri AB for reliable and innovative solutions if you are looking for injection molding services in Sweden.

2. Formteknik i Gislaved AB

Year of establishment: 1972

Number of employees: 300-399

Business type: FTEknik is an automation solutions provider that provides advanced engineering, production, and system integration solutions around the world.

Website and Contact

Website: https://www.fteknik.se/

Email: info@fteknik.se

Address: Verkstadsgatan 7, 332 35 Gislaved

Phone: 0371-58 67 70

Company Profile

Formteknik I Gislaved AB, situated in Gislaved, Swede,n is a company explicitly offering services in injection molds and the manufacturing of plastic components with a design and development unit. Their services include product development for mold creation, mold manufacturing and injection molding services with clean room facilities. It is unclear when the company was started and by whom, but Formteknik is defined by quality and has an enviable sustainability standard, bearing an ISO 14001 certificate. They deal with environmental issues and educate employees concerning them. Their key services include development, design, tooling, and injection molding, which are delivered according to the client’s requirements. Formtek’s value proposition is the flexibility of a production partner with innovative solutions that meet environmental standards.

Services

- Development/Construction

- Injection molding

- Forming tool

- Maintenance Services

Pros

1. Every standard operating procedure has its automation solutions that increase its efficiency and output.

2. Advanced Technology Integration – Empowers present-day control frameworks for executing precise operations.

3. Full Services Offered¬ – Offer design, installation, maintenance, and improvement throughout the continual utilization of the client’s systems.

Cons

1. Limited scope of applicability – Services can be effective only for the business of industrial automation and machinery industries.

2. Jimenez-Castillo et al. (2014) identified some automation process limitations: the high initial costs of automation systems and special-purpose machines.

3. Reliance on technology – In this system of work, there are always areas that require more tuning, and the system will, therefore, require more upgrades to ensure that there is no breakdown and that productivity is at its best.

If you are searching for injection molding services in Sweden, Formteknik I Gislaved AB offers you innovative and quality services.

3. Pdat Sweden Ab

Year of establishment: 2009

No. or employees: 50

Business type: PDAT Group offer services in areas of product design, tooling, rapid prototyping, injection molding and die casting services, PDAT international.

Website and contact

Website: https://www.pdatgroup.com/

Phone: (+46) 730 785700

Email: joacim.dahlberg@pdat.se

Address: Metangatan 1P, 431 53 Mölndal, Sverige

Company Profile

Pdat Group is a family company from Finland and produces main production tools for manufacturing industries. With nearly 30 years in business, they have prototyping, molding, and die-casting facilities and work with all plastics, rubber and metal specializing in aluminium and zinc. Both of them are located in Finland and China, and they marry the finesse usually associated with Finnish products with the working productivity of the Chinese labour force. Services offered cover design, rapid prototyping, tooling, and contract manufacturing, and it is an ISO 9001, 14001, and 13485 company. They have overseas centres in Finland, Estonia, Sweden, the United Kingdom, and Hong Kong, which offer reasonable customer service. Pdat Group relies on quality innovation, sustainability, and reliable manufacturing partners.

Services

- Product design services

- Prototypes

- Tooling

- Life cycle services

- Die casting service

- Injection molding service

Pros

1. Global Presence: PDAT Group has international markets, thus ensuring it has a large service consumer base and a baseball team of patrons.

2. Innovative Solutions: The firm offers solutions that address industry niches’ needs by providing products based on the latest technologies.

3. Customer-Centric Approach: Specifically focused on dealing with facets that have something to do with offering personal services and systems.

Cons

1. Costly for Small Enterprises: As specialized comprehensive solutions can be the best in technology and even efficient, they can be expensive to small businesses.

2. Regional Challenges: The maintenance of constant service delivery in diverse settings could be huge.

3. Complex Implementation: Complex technologies may take time and much effort to be integrated into an organization

To source reliable injection molding services in Sweden with acute accuracy, Pdat Sweden AB is a manufacturing company you could consider.

4 . Nolato Plastteknik AB

Year of Establishment: 1938

Number of employees: More than 5700

Business type: Nolato is a multi-industry organization of international operations for the design development, manufacture and supply of high-tech polymer products for Medical and Industrial applications as well as Consumer products.

Website and contact

Website: https://www.nolato.com/en/

Email: info@nolato.com

Phone: +46 431 44 22 90

Address: Nolatovägen 32, 269 78 Torekov, Sweden

Company Profile

Nolato is a Swedish company founded in 1938 by Nordiska Latexfabriken i Torekov that deals in polymer product solutions. Originally established in Torekov, Sweden, and renamed Nolato in 1982, the company has evolved through organic and acquired growth to become a world group. Although the founder’s identity still redirects the inquiries to the company communications, Nolato has grown its presence within Europe, Asia, and America and has been providing plastic manufacturing and injection molding services for a diverse range of industries with its specialties in plastics, silicone, TPE materials, and much more.

Initially, the company’s operations were conducted globally from Torekov. ISO certifications are followed at Nolato, and the company is committed to quality, sustainability, and improvement. Specializing in development through high-volume production, Nolato establishes itself as a strategic supplier of advanced polymer solutions for premier global manufacturers.

Services

- Virtual prototyping

- Injection molding of plastics

- Injection molding of silicone

- Dip molding

- Extrusion

- Decoration technologies

- Micro molding

- Compression molding

- Die-cutting technologies

Pros

1. Innovative Solutions: Amongst Nolato’s strengths is designing polymers and silicone that offer superior solutions for various sectors.

2. Customer-Centric Approach: Develop integrated technical production models, thus guaranteeing the right developmental models that mirror the clients’ needs.

3. Vertical Integration: Offers complete solutions, including designing and implementing prototypes right through to large-scale production, optimizing performance and quality assurance.

Cons

1. Dependency on Key Markets: A significant concentration on sectors such as medical and auto subjects it to fluctuations within the sectors.

2. High Operating Costs: The use of advanced manufacturing technologies, as well as increased efforts to embrace sustainable manufacturing, leads to increased operation costs.

3. Global Supply Chain Risks: Doing business operations in the international markets makes the company vulnerable to the fluctuations that emanate from geopolitical and economic instabilities.

For high-quality and innovative injection molding services in Sweden, connect with Nolato Plastteknik AB for tailored solutions.

5. DONGGUAN SINCERE TECH CO.LTD

Year of establishment: 2005

Number of employees:70-100

Business type: It delivers precision plastic injection molding services for various industries and improves the manufacturing industry all over the world by providing accurate service.

Website and contact

Website: https://plas.co/

Email: sales@cnm-mold.com

Phone: +86 (0)769-3388 9978

Fax: +86 (0)769-3388 9978

Address: 2nd industry area, TianTou Cun,HengLi Town,DongGuan City,GuanDong Province,China,523460

Company Profile

Plas.co is a reliable source of state-of-the-art plastic injection molding solutions for industries across the globe. Our core business is the manufacture of highly accurate plastic parts that are designed to deliver superior performance. Plas.co is a modern platform that uses the latest technologies and focuses on customers to help businesses improve their production processes effectively and safely. We have a broad range of services that can be adapted to suit the particular requirements of a given operation. Our focus at Plas.co is on sustainable solutions and meeting and exceeding customer expectations. Through technical knowledge and professionalism, we assist organizations to meet their objectives in the current global economy.

Services

- Product design and manufacturing

- Prototyping and testing

- Plastic mold design and manufacturing

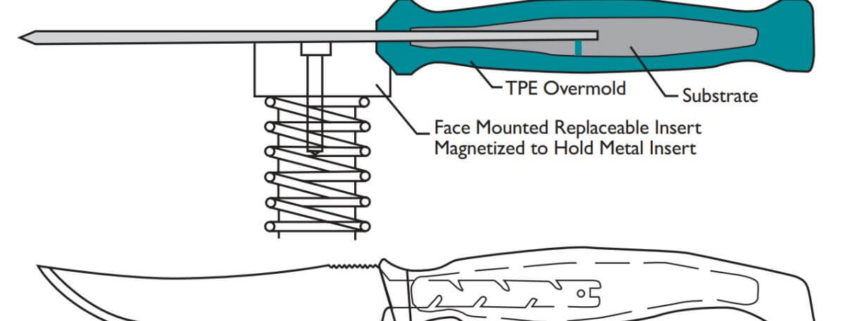

- 2K molding and overmolding

- PCB design and die-casting tooling

- CNC machining

- Certification services

- Mass production and assembly

- Inspection and packing solutions

Pros

1. Precision and Quality: Plas.co has precise plastic injection molding, which guarantees that parts’ dimensions are perfect and match industry standards.

2. Global Reach: Products and services can be customized to specific types of industries necessary to go through production processes around the globe that makes Plas.co a good business partner in the global market.

3. Innovation and Sustainability: The firm uses IT and employs sustainable work methods to meet the world’s contemporary sustainable standards.

Cons

1. Cost Considerations: The techniques like precision molding, the use of latest technologies may result in expensive products which may be bearish on small firms.

2. Specialization Needs: Specific or very specific requirements of a business may require further work and, consequently, more time.

3. Dependency on Technology: The heavy dependence on modern machinery might cause delay in the eventuality of mechanical breakdown.

When you need full service plastic injection molding, prototype development and finishing, and assembly, go with Plas.co.