Today’s injection molding industry in the United States has dramatically developed into a highly competitive and innovative manufacturing sector. As a key technology for converting plastic materials, injection molding is close to being a generic process that can effectively produce intricate parts economically. Injection molding is utilized in multiple industries, which include the automotive and aerospace industries, medical industries, and packaging industries to name but a few; injection molding is vital in industries where manufacturing includes large production of car parts, aerospace parts, and even the production of devices such as syringes and packaging materials. The United States houses some of the best and most efficient injection molding companies that provide advanced technologies, environmentally friendly methods, and virtually endless expansion of services.

In the following companies, the skills in mold design, parts prototyping, CNC machining, and final assembly are integrated to provide high-quality parts and products. They employ automation, robotics, and CAD to reduce time, improve efficiency on the production line, and improve quality. Also, today’s leaders are determined to achieve sustainability by promoting environmentally friendly materials and energy conservation even in the production line. Here are many options for prototype and machining manufacturers, first or second-tier suppliers, full-service high-volume production manufacturers, or custom parts manufacturers.

In this article, you will read about the 10 injection molding companies in the USA, their specialization, services, and roles in the industry.

1. Murray Plastics

Year of establishment: 1998

Number of employees: 250-299

Business type: Plastic Injection Molding Services, Parts, and Mold Manufacturing Company.

Address: 1922 Old Candler Rd, Gainesville, GA, United States, Georgia

Website and Contact

Website: MurrayPlastics.com

Email: bill@murrayplastics.com

Phone: +1 770-297-7000

Company Profile

Murray Plastics is a manufacturer from the USA that has been dealing in injection molding and mold building services since it was established in 1998. Founded in Gainesville, Georgia, the company deals with the electronics and packaging sectors, including design engineering, tooling, and production. Specializing in thermoplastics and polyurethane, they provide excellent parts with a state-of-the-art molding process. Proudly supporting local manufacturers, Murray Plastics offers practical solutions at a superior value, including transport and timely delivery across various sectors.

Services

· Plastic Mold Design and Engineering

· Plastic Injection Molding

· Injection Mold Building

· Prototype Development

· Quality Control and Testing

Pros

1. Energy Saving – The product reduces energy consumption when manufacturing plastic components.

2. Custom Solutions – Prescribes unique designs and choices of materials that would fit different uses.

3. U.S.-Based Manufacturing – Provides for faster production and delivery with a local support guarantee.

Cons

1. Fixed Cost – Creating a tool and mold may initially sound pricey.

2. Mechanical Limitations – Cannot be used with materials that have crystalline structures.

3. Volume Dependency – It is not that cheap at low volumes.

2. MSI Mold

Year of establishment: 2005

Number of employees: 51-200

Business type: MSI Mold company provides plastic injection molding services, CNC machining service, mold making service, prototype service and custom plastic parts service.

Website and Contact

Website: www.msi-mold.com

Email: sales@msi-mold.com

Address: 2045 S. Almont Ave, Imlay City, MI 48444

Phone: (248) 870-3039

Company Profile

MSI Molding is a high-quality plastic injection molding company specializing in offering company-specific applications in the automotive, electronics, and medical device industries. The company now works with modern technology and sophisticated equipment to facilitate engineering processes. Like most injection molding processes, plastic is advantageous in terms of high production volume and efficiency, material flexibility, and cost-effectiveness in generating intricate prototypes, short-run manufacturing of complex designs, and varied uses across industries.

Services

- Plastic injection molds

- Custom injection molding

- Prototype injection molding

- Design and engineering

- Assembly and extras

Pros

1. The best choice for intricate designs for the highest levels of accuracy.

2. Cost-effective, mainly when used to produce many products, thereby maintaining standardization.

3. Multi-functional, accommodative to various materials and uses.

Cons

1. A high initial cost of creating the mold.

2. Are typically confined to particular kinds of materials.

3. Higher minimum number of parts per batch that it can manufacture and a longer setup time for small production runs.

If you require plastic injection molding services in the USA, please call MSI Molding now.

3. UNIVERSAL PLASTIC MOLD

Year of establishment: 1972

Number of employees: 200-300

Address: Office Address: 13245 Los Angeles St, Baldwin Park, CA, United States, California

Business Type: Universal Plastic Mold (UPM) is in large-part plastic injection molding, plastic molding tools, assembly, and supply or transportation, mold maintenance etc.

Website and contact

Website: https://www.upminc.com

Phone: 1-888-893-1587

Phone: +1 626-962-4001

Email: sales@upminc.com

Company Profile

Universal Plastic Mold (UPM) is a California-based company ranked among the top leaders in plastic injection molding. It has been in the industry for over five decades and has acquired an ISO certification. UPM runs all year, performing different functions like prototyping, designing tools, assembling, and delivery. The finishing process manufacturer of automotive, medical, packaging, and solar implements, UPM features versatile capabilities. They are family-owned with a focus on quality and efficiency whilst offering over 80 products successfully launched in the market.

Services

- Tooling and plastic fabrication

- Plastic custom injection molding

- Assembly services

- Water injection

- Program Management

- Plastic Mold Repair Maintenance

Pros

1. 51-plus years of experience providing unique custom plastic injection molding.

2. Full-scope services provide within-house solutions to reduce the production and supply cycle.

3. Round-the-clock services and state-of-the-art equipment for multiple sectors.

Cons

1. Specializing in medium and large part molding, with reduced capacity for small molding works.

2. If machinery is highly dependent on then there might be a rise in maintenance costs.

3. Like any other established plastic manufacturer, there is competition in the market.

If you are searching for plastic injection molding manufacturing in the USA, please visit Universal Plastic Mold.

4. The Rodon Group

Year of establishment: 1956

No or employees: 100-150

Business type: Sophisticated production, molds making, corporate responsibility, quality assurance, affordability, and polymers industry specialization.

Website and contact

Website: https://www.rodongroup.com

Phone: +1 215-822-5544

Email: sales@rodongroup.com

Address: 2800 Sterling Dr, Hatfield, PA, United States, Pennsylvania

Company Profile

The Rodon Group was established in 1956 in Hatfield, Pennsylvania, and is a family business specializing in plastic vertical injection molding and operating a 125,000-square-foot ISO 9001: This 2015 certified landfill-free facility contains over 125 runs, producing billions of parts yearly. Operating in mold design and manufacturing, tool making, and short-run, high-volume production for industries like Medical and Consumer Products, they focus on customers’ sustainable advantage, leveraging precise, cost-effective, and environmentally sound solutions for various manufacturing requirements.

Services

- Plastic injection molding

- Manufacturing

- Tool making

- Material selection

- Large-scale production of lightweight plastic components

- Production involves custom plastic injection molding

- Little or no usage of landfill for disposal

Pros

1. ISO 9001: Maron is also 2015 certified, thus passing high quality standards of the company.

2. Operations free from using landfills, focusing on environmentally friendly processes.

3. The level of competition in the domestic markets removes the essence of sourcing products from other countries.

Cons

1. It is restricted only to large-scale production and avoids small-scale production.

2. Tooling and mold design costs are among the highest for green electronics at the beginning of implementation.

3. This is various because it is confined to industries that fit the injection molding methods.

If you need plastic injection molding services in the USA, visit The Rodon Group!

5. Plastimold Products

Year of Establishment: 1998

Number of employees:50-100

Business type: Specializing in providing building injection molding services, product design, prototype, mold manufacturing, mechanical assembly, and material sourcing.

Website and contact

Website: https://plastimoldproducts.com

Email: hello@plastimoldproducts.com

Phone: +1 561-869-0183

Address: 250 N Congress Ave, Delray Beach, FL, United States, FL

Company Profile

Plastimold Products is a company engaged in plastic injection molding founded in Delray Beach, Florida, U.S.A, in 1998. The company offers design services, such as creating molds, prototyping, and assembly. They run a hi-tech, ISO-compliant factory day and night for their production, which is focused and environmentally friendly. Plastimold produces for industries such as medical, aerospace, and consumer goods to provide dependable value-for-money solutions and be a reliable manufacturing partner in the global market.

Services

- Plastic injection molding

- Plastic product design

- Inert molding

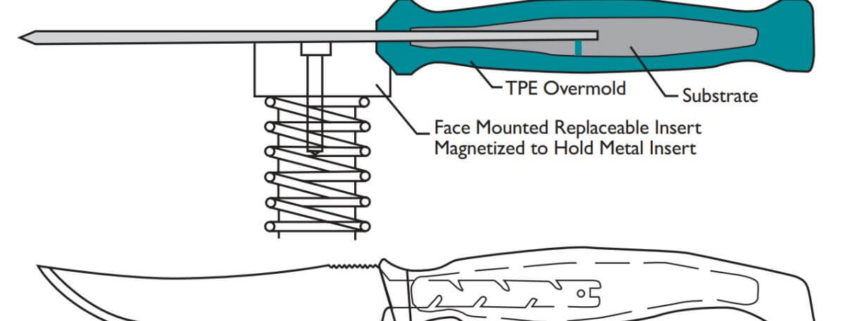

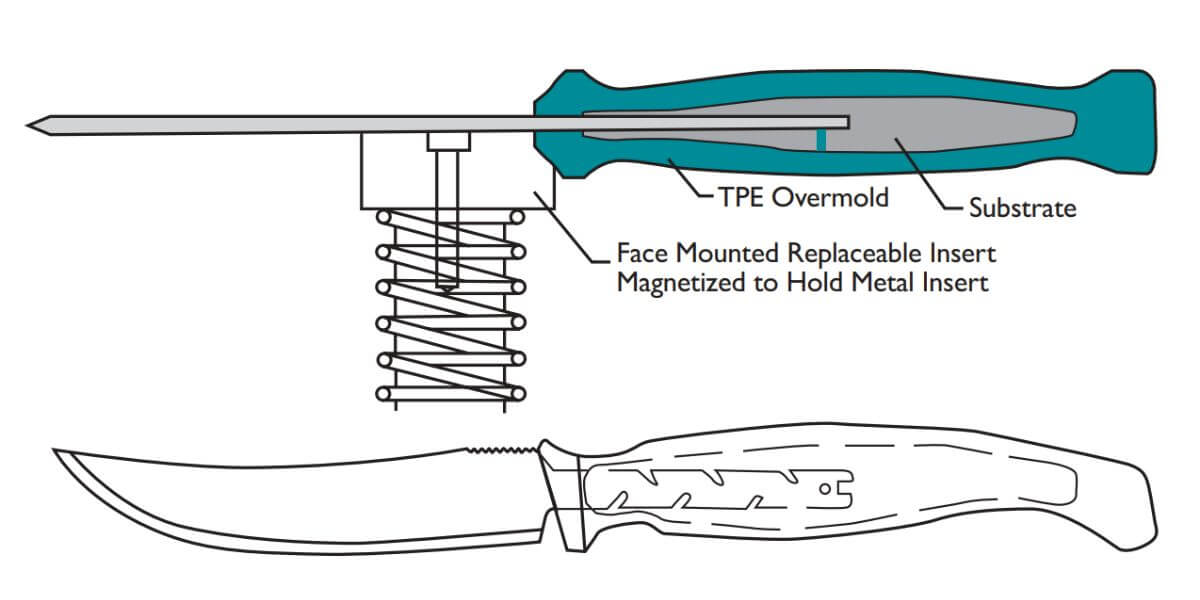

- It is also called over molding injection molding

- Mold transfer management

- Prototyping

- Assembling

Pros

1. An authorized production center provides good quality and accuracy as it complies with the requirements of ISO standards.

2. The fact that automated processes run around the clock makes them more productive and less expensive.

3. A wide range of industries specializing in services that require complex mechanics, such as health, aviation, and manufacturing industries, with manufactured products that include consumer goods.

Cons

1. This suggests that high-volume production is not ideal for small-demand situations.

2. It is also important to note that while setting up a mold project, an individual might incur vast sums to create it.

3. Well-suited operations may not necessarily provide services for other manufacturing that is non-plastic.

To get the best services in plastic injection molding, contact Plastimold Products!

6. Hi-Tech Mold & Engineering, Inc.

Year of Establishment: 1982

Number of employees: 300-400

Business type: This company provides plastics and tooling services throughout the mold design, machining, molding, and assembly processes.

Website and contact

Website: https://www.hitechmold.com

Email: employment@hitechmold.com

Phone: +1 248-852-6600

Address: 2775 Commerce Dr, Rochester Hills, MI, United States, Michigan

Company Profile

Hi-Tech Mold & Engineering, founded in 1982 in Rochester Hills, Michigan, supplies products and services for the plastics and tooling industries. Operating in mold design and manufacturing, CNC turning and milling, 3D printing, injection molding, and assembling, the company works with the automotive, aerospace, and medical industries. Certified to IATF 16949 and ISO 9001: In 2015, Hi-Tech set strategic goals focusing on innovation, quality, and improvement to provide the highest quality solutions developed in the technologically advanced center.

Services

- CNC Machining

- Additive Manufacturing

- Plastic parts through Injection Molding

- Value-added assembly

- Product design and development

Pros

1. Certified to IATF 16949 and ISO 9001: In 2015, achieving the highest quality of services became the foremost priority.

2. Provides coverage from mold design to added-value assembly services.

3. It involves various sectors, such as the automobile, aviation, and healthcare industries.

Cons

1. Specialization tends to bar more fantastic applications to other areas or organizations.

2. High initial costs of creating molds for creating the molded articles.

3. Not cost-effective or efficient for companies with low volume demands for their product.

Are you seeking new plastics and mold tooling ideas? Hi-Tech Mold is the right company you need to contact.

7. Bennett Plastics

Year of Establishment: 1982

Number of employees: 80-200

Business type: Specializing in designing, manufacturing, molding and assembling, injection molding plastic products and packaging.

Website and contact

Website: https://www.bennettplastics.com

Email: info@bennettplastics.com

Phone: +1 973 684 1501

Address: 22 Kentucky Avenue, Paterson, New Jersey 07503

Company Profile

Bennett Plastics, which started in 1982 in Paterson, New Jersey, offers plastic injection molding services. The company has more than 40 years of experience and specializes in product design, engineering, mold making, and assembling designed products. Using the state-of-the-art equipment, they offer services ranging from 75-500 tones and assure quality and accuracy. Reporting to consumer goods, electronics, and medical devices, Bennett Plastics focuses on sustainability, customer services, cost-effectiveness, and quality in manufacturing its custom-designed, value-added plastic parts.

Services

- Specialty Plastic/Medical and Orthopedic / Injection Molding

- Both Product Design and Engineering

- Mold Making and Maintenance

- Assembly and Packaging

- Further Processing Services/Services after Labeling

Pros

1. Practical experience in injection molding processes of over 40 years.

2. Sophisticated tools make the work as accurate as possible and the products as high quality as possible.

3. Full service from architecture to packs from one umbrella.

Cons

1. Small to medium-scale projects may not be an issue, but massive projects may be hampered by limited machine capacity (75-500 tons).

2. Concentration on plastics eliminates other manufacturing materials.

3. The necessity of the investments when creating individual molds.

If you need sound plastic injection molding services, visit Bennett Plastics now.

8. PlastiCert, Inc.

Year of Establishment: 1981

Number of employees: 50-100

Business type: Custom plastic injection molded providing services in the design & manufacturing of molds, over-molding, and added services.

Website and contact

Phone: +1 507-523-2300

Website: https://www.plasticert.com

Email: lewiston@plasticert.com

Address: 300 Wilson St N, Lewiston, M, N United States, Minnesota

Company Profile

PlastiCert Inc., founded in 1981 and located in Lewiston, Minnesota, offers custom plastic injection molding services. Having capabilities in mold design, insert molding, over molding, and secondary operations/plastics assembly, PlastiCert serves sectors such as aviation, telecommunications, and heating/ventilation/air conditioning (HVAC). ISO 9001: Incorporated in 2015 and UL registered, the company values quality and creativity. PlastiCert has been in the business of providing OEMs with reliable plastic molding services for over 40 years.

Services

- Plastic Injection Mold, Special Plastic Injection Mold

- Mold Design and Development

- Insert Molding

- Over molding

- Decoration and Electro-Mechanical Assembly as Value Added Services

Pros

1. More than 40 years of experience in plastic injection molding.

2. ISO 9001:It has been certified since 2015 to verify the company’s quality standards.

3. Manufacturing services: facilities ranging from simple mold design to over molding and other additional assembly services.

Cons

1. Designed for moderate and low production capacities, which prevents the company from handling large scales.

2. Mentioned to focus predominantly on particular sectors, which minimizes the field of its use.

3. The options often come with higher initial costs in the tooling and design of the parts.

If you need the best and most affordable plastic injection molding service, PlastiCert is the right choice!

9. LS Hardware Tech Co., Ltd

Year of establishment: 2008

Number of employees: 200-300

Business type: International manufacturer of prototypes and Precision parts through milling services and injection molding.

Website and contact

Website: https://www.lsrpf.com

Email: info@longshengmfg.com

Phone: +15168866992

Address: USA

Company Profile

Located in Shenzhen, China, with an operation center in California, USA, Longsheng Manufacturing (LS) specializes in prototype and short-run production. Operating 3D printing, CNC machining, metal fabrication, and injection molding services, LS caters to the automotive, aerospace, and medical device manufacturing industries. Certified with ISO 9001:ISO 13485:2015, ISO 13485:2015, AS9100D, LS leverages innovative technology, rapid turnaround, and worldwide presence to provide accurate, affordable manufacturing services accompanied by outstanding customer service.

Services

- CNC machining

- Injection molding

- Metal casting

- 3D printing

- Rapid prototyping

- Surface finishing

Pros

1. Source of production in China and availability of local support in the USA.

2. Relatively a short lead time with the possibility of starting production from one business day.

3. Computer-controlled machining methods, additive manufacturing technologies, and injection molding.

Cons

1. Its methods of managing international operations can bring some complexity to supply chains.

2. It may, however, reduce its appeal, especially with small or niche firms.

3. Costs may be higher when a solution has been tailored and made.

If you want consistent injection molding solutions, Longsheng Manufacturing is the right solution provider globally.

10. Sincere Tech

Year of establishment: 2005

Number of employees: 50-200

Business type: Commercial plastic injection mold maker, die-cast mold maker, mold maker for RTV silicone rubber, product assembly services, prototype maker, and manufacturer.

Website and contact

Website: www.plasticmold.net/

Email: info@plasticmold.net

Phone: +86 135 30801277

Address: ChangPing, Dongguan City, Guangdong Province, China

Company Profile

Sincere Tech, located in Dongguan City, Guangdong Province, China, specializes in producing plastic injection mold, die casting mold, and silicone rubber mold for the electronics manufacturing industry since 2005, established by Mr. Wang Lei. The company’s manufacturing specializations are mold design, prototype manufacturing, and assembly. Certified in ISO 9001: Environmental Endorsement Standards: 2015; Sincere Tech Standard: ISO 14001, New Car QC Standard: ISO 14001:2015, Automotive Industry Technical Standard: IATF 16949, Sincere Tech Business scopes involve automotive, medical, and electronic industries to bring innovation, high quality, and customer-oriented service to the global market.

Services

- Plastic Injection Molded Products

- Die Casting Molds

- Silicone Rubber Molding

- Prototyping Service

- Full Product Assembly

- Mold Design and Manufacturing

- Product Packaging

- Secondary operations include painting, printing, and welding, among others

Pros

1. The top-notch tier of custom mold products made from state-of-the-art technology with an emphasis on workmanship.

2. Certifications like ISO 9001:2015, ISO 14001:2015, and IATF 16949 in 2016 guarantee quality and compliance.

3. Designing the mold, producing the required parts, and assembling a complete product.

Cons

1. There is a risk of business with an extended delivery lead time for international clients since most manufacturing facilities are in China.

2. One disadvantage of establishing a form is that there are usually enormous fixed costs associated with constructing custom molds for large projects because of their size.

3. Most branches Lack direct client servicing outbound from the region.

So, if you want authentic custom mold manufacturing and assembling solutions, visit Sincere Tech.