Why TPU Injection Molding Is Ideal for Soft Parts?

Why TPU injection molding is ideal for soft parts? As this blog shows, TPU has few peers when it comes to the advantages it offers. TPU has the advantages of flexibility, heat resistance, and chemical incombustibility. This is due to the fact that injection molding allows accurate production to be made.

Now let’s discuss the properties that give an advantage to TPU.

What Are the Unique Properties of TPU That Make It Suitable for Soft Parts?

Flexibility

Shear modulus around 1000 psi is advantageous in the formation of soft parts. Injection pressure is used to properly align molecular chains. TPU’s Shore hardness varies between 60A and 98A.

This range enables creation of various soft parts. Molding precision is affected by tensile strength. This property is useful for automotive and consumer goods.

Modulus flexibility is well applicable for ergonomic designs. Flexural strength helps dynamic components. Mold temperature affects the flexibility of the final part. Injection speed determines the flow characteristics of the polymer.

Elasticity

Tensile elastic modulus defines stretch as well as recovery properties of a material. Dynamic application requires high strain capacity. TPU’s elongation at break is more than 500. This parameter guarantees reliability in parts. Low compression set enhances performance as it can withstand stress.

The injection parameters determine mechanical properties. Elasticity is useful for seals, gaskets, and flexible tubing. Young’s modulus informs design requirements.

Elasticity is achieved when the mold temperature is correctly regulated. The characteristics of the final product depend on the conditions under which it is processed.

Durability

In Taber test abrasion resistance is more than 200 cycles. Injection molding parameters improve surface hardness. Tensile strength is an essential factor for durable parts in TPU.

Flexural fatigue endurance provides durability for applications that involve rotational or bending movements. They vary from 85A to 95A. This range gives support to structures.

Impact resistance at low temperature provides more durability. Mold design determines the extent to which the final product shall be durable. TPU’s resistance to mechanical wear makes it suitable for use in industrial parts.

Chemical Resistance

Thus, the resistance to hydrocarbons provides stable characteristics of material properties in extreme conditions. It retains the part integrity as water absorption is kept to a minimum. TPU exhibits good resistance to oils and fuels. Chemical resistance properties depend on injection conditions.

This feature is valuable for high-performance applications. Components such as hoses and seals require chemical compatibility. This trait is provided by TPU’s molecular structure.

Processing control is relevant to sustainable resistance. TPU’s resistance to swell under solvents adds to its durability. Injection speed and temperature are among the factors that affect resistance.

Temperature Adaptability

Thermal stability varies between – 40 and 100. Injection process retains this flexibility. Glass transition temperature of TPU affects its performance. It is advantageous in a broad range of applications across climate zones. The processing parameters have been reported to affect the thermal properties.

Stability of performance under a varying temperature is important. This is used in automotive and aerospace industries. Temperature control of the mould is very important.

TPU’s versatility contributes towards product longevity. Thermal stability is achieved through accurate processing.

How Does TPU Injection Molding Differ from Other Types of Plastic Molding?

Thermoplastic Comparison

TPU plastic injection molding has a processing temperature of between 190 and 230. This is lower than for many thermoplastics. The low shear viscosity of TPU benefits the molding of complex parts. Other thermoplastics, such as PP, require higher pressures.

The melt flow index of TPU leads to ease in injection. TPU has a better elongation than PET. Injection speeds differ due to TPU’s relatively different rheology. TPU has a much slower rate of thermal dissipation compared to ABS.

Specific Challenges

Moisture control in material handling should be below 0.03. The mold design is made difficult due to high sensitivity to processing parameters.

At processing temperatures TPU has a lower viscosity compared to PVC. Another factor that has to be closely monitored is the rates of cooling as this affects the stability of dimensions. High mold shrinkage of TPU must be taken into consideration on the tooling side.

The demolding process requires close control of temperature. Screws used for processing TPU require specific designs. The low melt strength of TPU is a problem at TPU. Changes in injection pressure have an impact on the quality of the parts produced.

TPU Injection Molding Advantages

Due to the high flexibility, TPU injection molding is suitable for application in dynamic parts. Recall the principle of elasticity, which guarantees the ability to withstand the load continuously and for a long time.

High wear resistance is ideal for industrial use. The ability to cover a large hardness range improves versatility at TPU. Another advantage of chemical resistance is for the automotive parts. Due to the low-temperature performance of TPU, its application expands.

High transparency options are suitable in the consumer goods sector. Good adhesion makes overmolding possible. The biocompatibility of TPU allows its use in the field of medicine. Mandatory control of mechanical properties leads to the high quality of final products.

Why Is TPU Preferred Over Other Materials for Flexible and Durable Parts?

Performance Characteristics

High tensile strength is beneficial in making TPU injection molding parts more durable. High elongation at break suggests that the material is flexible. Low compression set helps retain the shape of the material under stress.

TPU’s abrasion resistance also increases durability. High tear strength provides for high performance usage. Elastic modulus determines both flexibility and rigidity.

Shore hardness range makes it possible to use it in different ways. TPU’s chemical resistance means stability. Flexibility at low temperatures is adapted for various conditions. Injection parameters allow for enhancing performance characteristics.

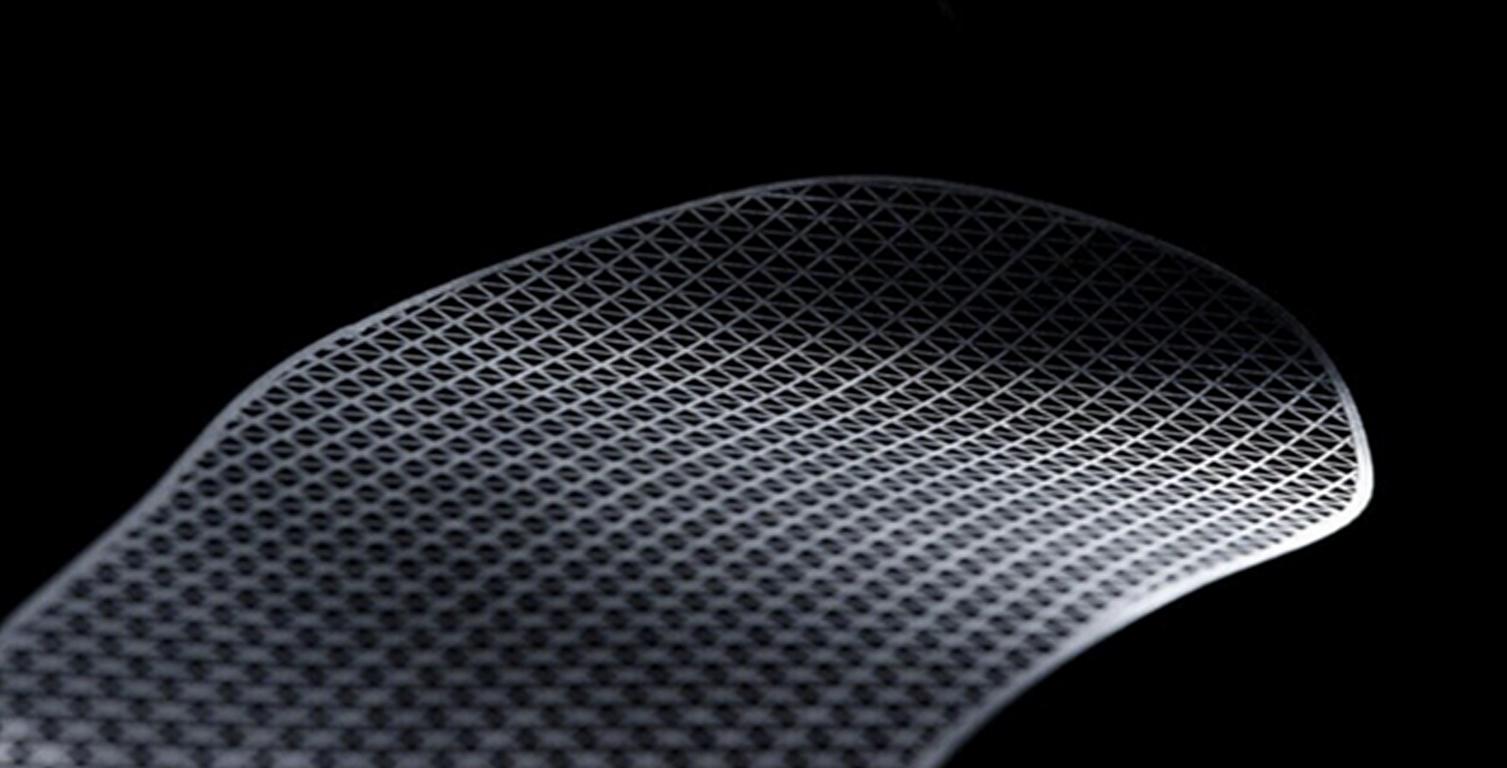

Superior Flexibility

The value of the elastic modulus allows for higher flexibility of the components made of TPU. High elongation at break indicates that the material is stretchable. Tpu has good resiliency for dynamic applications. The compression set at low levels keeps flexibility of the material under stress.

Good rebound characteristics contribute to improved performance levels. The existence of shore hardness range shows that the flexibility range is variable.

Flexural strength helps in making soft and flexible parts. Due to TPU’s molecular structure, flexibility is maintained throughout the product. Control processing makes materials highly flexible. Due to its flexibility, TPU is equally advantageous in design versatility.

Long-term Benefits

Abrosion resistance guarantees the long-term use of injection molding TPU parts. Chemical stability is the ability to sustain its performance level throughout the usage period. The low temperature impact resistance also increases product life. High tear strength contributes to the increased durability of products.

TPU’s resistance helps alleviate material fatigue. High elasticity ensures increased flexibility in the longer run. Low moisture absorption is another factor that favors its durability.

Reliability is therefore defined as the ability to perform under different conditions in a consistent manner. Thus, the stability of TPU’s environment minimizes degradation. Durability saves costs in the long-term since TPU is highly efficient.

Material Resilience

The fabric’s tear strength increases due to the incorporation of TPU in the material. Outstanding wear characteristics make the product suitable for demanding uses.

The measure known as elastic modulus defines strength and flexibility in balance. Low compression set does not allow the structure to maintain its shape. Chemical resistance of TPU allows maintaining stability of the material. The ability to withstand low temperatures eliminates the risk of being brittle.

TPU’s flexibility decreases the chances of material stress. High impact strength provides lasting components. This is because consistency over a period of time increases reliability. TPU’s versatility makes it appropriate for various uses.

What Are the Key Considerations in Designing for TPU Injection Molding?

Wall Thickness

Wall thickness plays a critical role in TPU plastic injection molding part functionality. Thin walls minimize the amount of material used in construction. Uniform thickness prevents warping. Proper thickness ensures strength.

Wall formation depends on injection pressure. Flexibility of TPU means that some specific dimensions of the walls are needed. Thickness variations also affect cooling rates.

Lightweight designs are favored by thin walls. For thicker sections, reinforcement may be required. More thickness leads to longer and stronger walls.

Draft Angles

Coordinates help in the proper ejection. It is also found that TPU injection moulding parts require sufficient draft for the demolding process. Incorrect angles cause defects. Due to its high elasticity, TPU injection molding can be used in the production of elements with lower draft angles. Proper draft averts uneven surface.

High draft angles minimize stresses in the material as well. Mold design must also consider the flexibility of TPU. Draft optimization makes sure that the quality that is produced is uniform throughout the production process. The ejection force is directly proportional to the draft angles. Higher accuracy of the draft angles decreases the cycle time.

Rib Placement

Ribs help in improving the strength of TPU plastic injection molding part. Appropriate rib construction reduces twisting. Thickness of ribs should be less than that of the walls. Placement affects material flow.

Minimize the sharp corners when designing ribs. Increased rib spacing optimizes flexibility in TPU. TPU injection mold should correspond to stress lines. Excessive ribs can lead to formation of sink marks.

Equal distribution of ribs increases load bearing capacity. It is also important to note that the shape of ribs significantly affects the cooling process.

Material Flow

Material flow impacts on the quality of the TPU injection molded part. The first one is on flow rules where proper flow eliminates formation of voids and defects. The low viscosity of TPU contributes to flow.

Location of gates affects the flow. The balanced flow of materials and components helps in the reduction of internal stresses. Flow rate affects the final part characteristics.

Due to the high flexibility, the flow in TPU has to be managed properly. Computational fluid dynamics application enhances the mold design. Proper flow also plays an important role in providing a right pattern of material flow. Flow channels need to take into account the nature of TPU.

Cooling Considerations

Therefore, rate of cooling has implications on TPU injectino molding part quality. Another disadvantage of adopting this method is that such a rate of cooling is likely to lead to warping. Uniform cooling preserves dimensions to prevent warping. Due to its low coefficient of thermal conductivity, there are certain cooling methods for TPU injection mold. One of the factors affecting the cooling rate is the mold temperature.

Cooling channels have to be well designed. Optimal cooling improves the mechanical characteristics of TPU. Stress can occur due to uneven cooling. This is because TPU’s flexibility is enhanced by controlled cooling. This means that cooling time has a direct impact on the specific manufacturing cycle.

How Does the TPU Injection Molding Process Work?

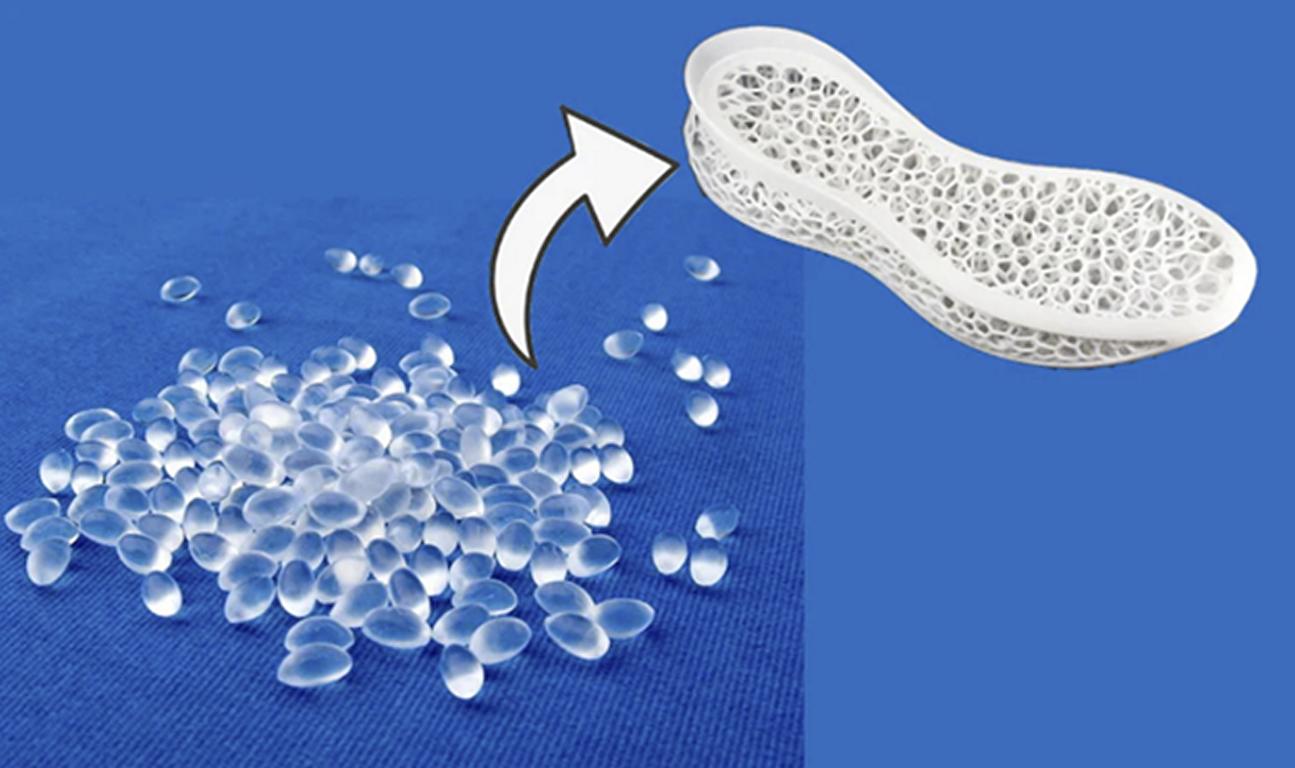

Process Overview

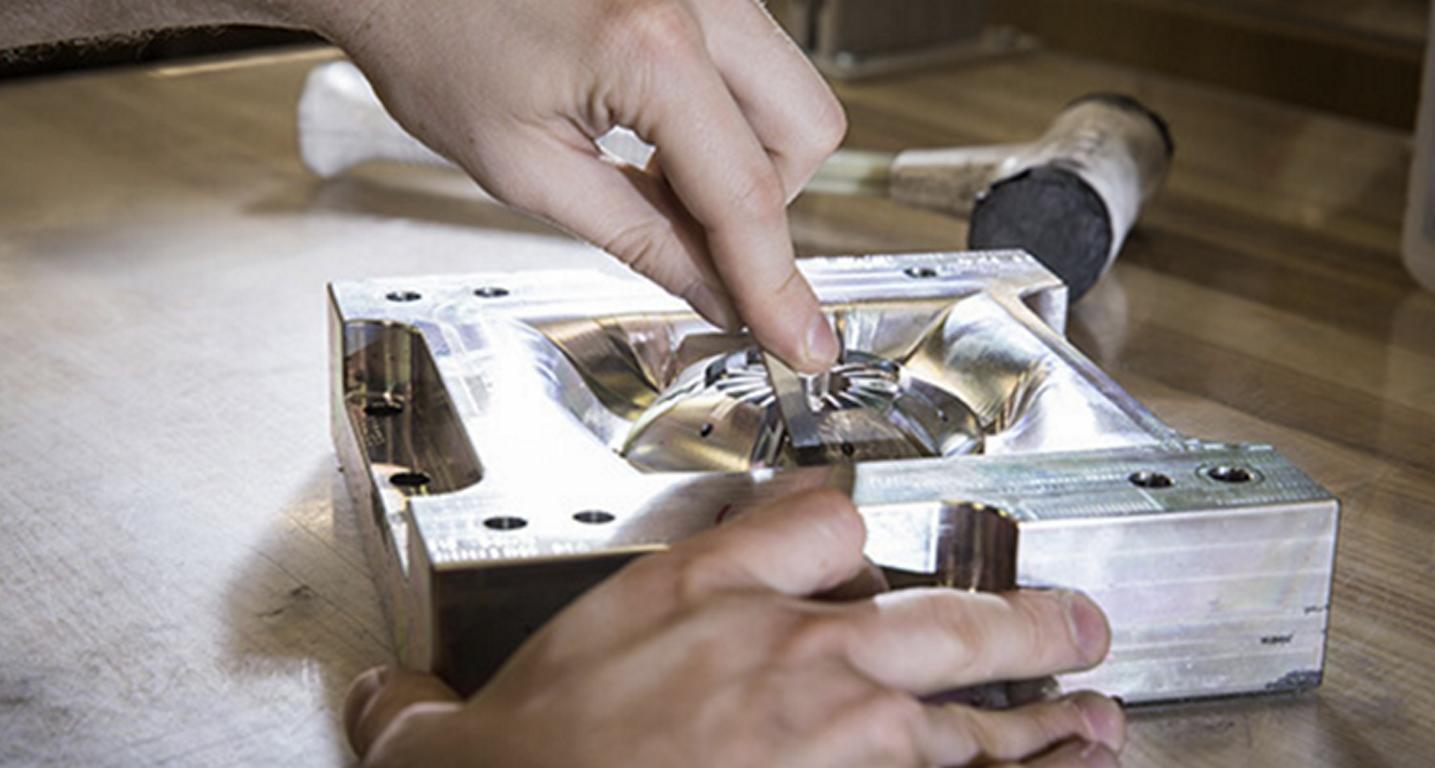

TPU granules melt in the injection unit. TPU is injected in a mold cavity in its molten state. Injection pressure and speed control the mold filling process. The TPU hardens to the desired shape through the process of cooling. Ejection system helps in the removal of the molded part.

TPU has a low viscosity hence it can easily flow and be processed. Thus, mold temperature plays an important role in avoiding defects. Cyclic injection time affects production rate. Mold design determines the quality of the final part.

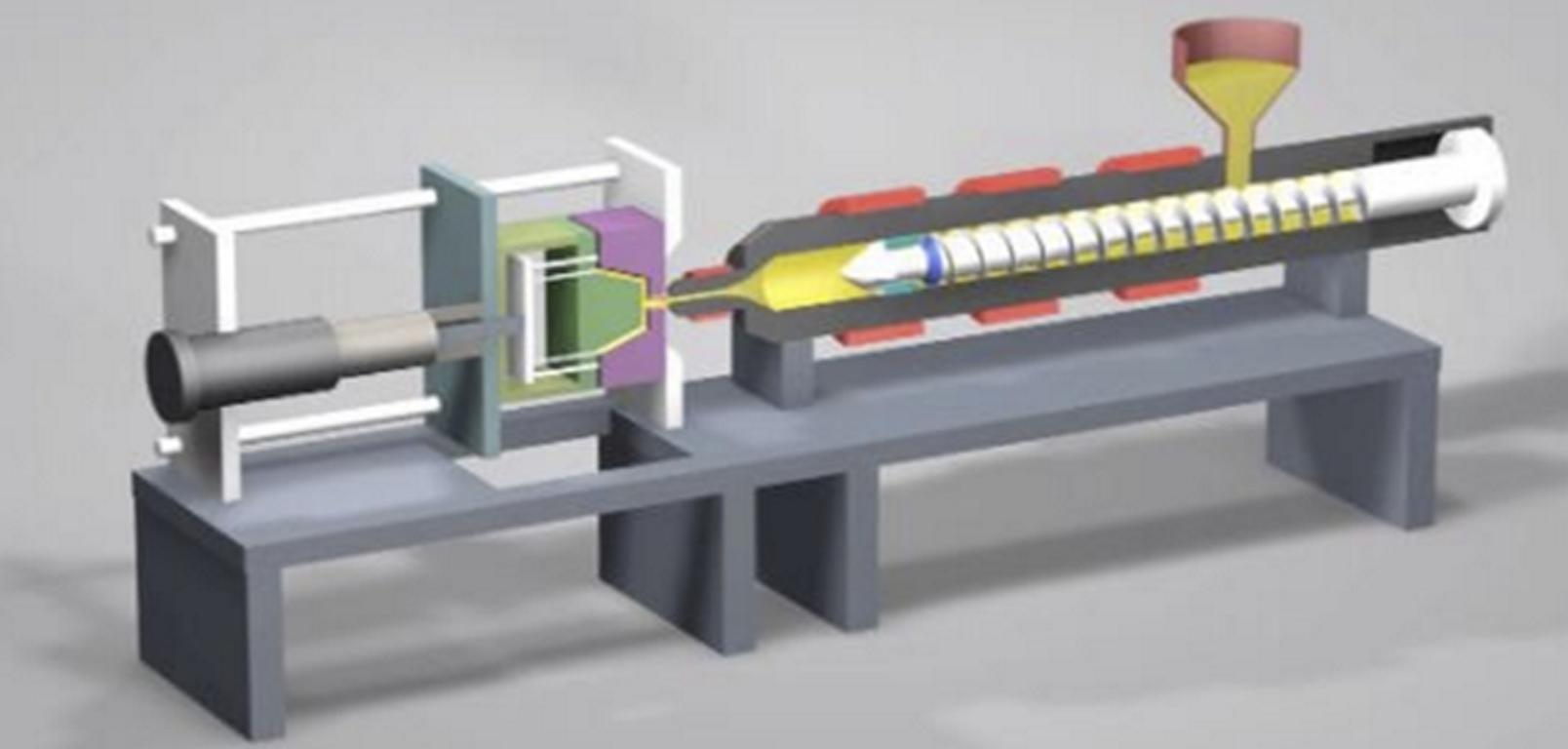

Specific Machinery

The injection molding machines employ a reciprocating screw. The barrel melts TPU granules through heating. The clamping unit is responsible for securely holding the mold in position.

Temperature management helps TPU maintain its uniformity. The TPU is injected into the mold under high pressure. Most of the machinery is hydraulically or electrically powered.

Control of solidification is achieved through mold cooling systems. Part removal may be assisted by robotic arms. Sensors monitor injection parameters. The low shear viscosity of TPU makes these machines suitable for its use.

Quality Control

Verification of dimensional accuracy is done after molding. Surface finish inspection proves that the product does not have any defects. Tensile strength tests are important since they confirm the quality of materials. Overall, hardness testing also supports the TPU’s specifications.

It is important to keep the machinery on a regular calibration schedule to ensure its optimal performance. Temperature of the mold is monitored to avoid variation. Production quality is monitored through data logging in real-time. Visibility inspections detect surface defects.

For dimensional stability, shrinkage is also measured. As a result of standardized quality assurance, TPU injection molding parts are dependable.

Testing Procedures

To determine the tensile strength of TPU, tensile tests are conducted. Thus, hardness tests help to determine material characteristics and confirm its properties. Elongation tests assess flexibility. Wear properties are determined by Abrasion resistance tests.

Chemical resistance tests are aimed at checking stability. Toughness of TPU is determined through impact tests. Dimensional checks confirm the accuracy of the mold. Thermal analysis checks temperature characteristics. Carbon dioxide emission tests show impact on environment.

This confirms that TPU meets set specifications by conducting testing on a regular basis.

What Are the Post-Molding Processes for TPU Parts?

Finishing Techniques

Trimming allows cutting the unnecessary portions of TPU material. Polishing enhances surface smoothness. Painting provides colors and surface polish. Laser marking gives detailed information in a precise manner. Ultrasonic welding is used to join TPU parts.

Buffing removes minor imperfections. Solvent wiping removes the debris from the surface. Heat staking secures components. Pad printing involves applying graphics or text. Each technique helps to achieve a high-quality final TPU product.

Deburring

Manual deburring takes off sharp edges. Tumbling cleans and deburrs parts. Automated systems enhance efficiency. Precision tools ensure accuracy.

Deburring prevents part defects. TPU’s properties are preserved by appropriate technique. Small burrs are removed by rotary brushes. Deburring is crucial for safety. Each method helps to ensure that the parts produced by injection molding tpu meet the necessary requirements.

Surface Treatments

Plasma treatment enhances the TPU adhesion. Coatings enhance chemical resistance. UV curing is used to solidify surface coatings. Etching provides texture. Anti-static treatments minimize dust accumulation. Surface sealing enhances durability. These treatments apply to TPU parts.

Chemical treatments enhance the surface characteristics of the material. Corona treatment alters the surface energy. All of them adapt the TPU surfaces for certain purposes.

Consideration | Description | Ideal Values/Guidelines | Impact on Quality |

Wall Thickness | Uniformity, strength, flow | 0.5-3.0 mm | Consistency, strength |

Draft Angles | Ejection ease, mold life | 1-3° per side | Mold release, durability |

Rib Placement | Reinforcement, stiffness | 50-60% of wall thickness | Structural integrity |

Material Flow | Consistency, complete filling | Proper gating, venting | Surface finish, strength |

Cooling Considerations | Cycle time, dimensional accuracy | Uniform cooling channels | Reduced cycle time |

Table on the Key Considerations in Designing for TPU Injection Molding!

Conclusion

Thus, TPU plastic injection molding is best suitable for soft parts. It should be noted that TPU is suitable for various industries and guarantees high-quality work. Visit plas.co for expert insights.