PMMA injection molding

Polymethyl methacrylate (PMMA), which is also known as “acrylic,” is a clear thermoplastic material that is famous for being very strong, very clear and very resistant to weather. This article dives into the world of PMMA injection molding talking about its pros, cons and important factors for picking reputable PMMA injection molding companies.

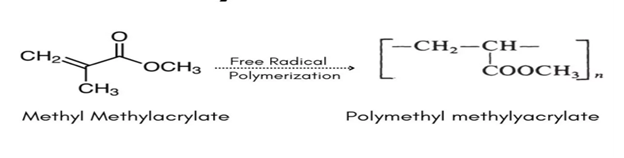

How PMMA is made:

Acrylic is a synthetic material made of repeating units of the monomer methyl methacrylate. It is also commonly referred to as polymethyl methacrylate (PMMA). PMMA is made up of several chains of methyl methacrylate molecules joined at the molecular level by a methyl acrylate group. Because there is little to no distortion of light as it goes through the material, this optical structure enhances its transparency. Under certain circumstances, PMMA’s exceptional optical transparency can even outperform that of glass. Fiber is a top choice for transparent goods and applications due to its lightweight and optical qualities.

Different Kinds of Acrylic?

There are different types of acrylic materials for PMMA injection molding and each has advantages and disadvantages.

1. Polymethyl Methacrylate (PMMA):

Polymethyl methacrylate (PMMA) is also known as acrylic or Plexiglas and is the most common type of acrylic. Excellent weather resistance, impact resistance and optical quality are some of its qualities.

2. Poly (methyl methacrylate-co-methyl acrylate) (PMMA-MA) :

It consists of methyl methacrylate and methyl acrylate in the copolymer composition. It also has the characteristics of PMMA, in addition to increased flexibility and impact resistance.

3. PMMA-EA:

It is one of the copolymers that introduces the ethyl acrylate monomer, which is very similar to PMMA-MA. It is known as a greater degree of flexibility plus impact endurance.

4. PMMA-BA (poly ethyl methyl methacrylate-co-butyl acrylate):

It is a copolymer that combines PMMA advantages with improved flexibility, impact resistance, and chemical resistance since these monomers contain butyl acrylate.

What is the color of PMMA?

It is a copolymer that combines PMMA advantages with improved flexibility, impact resistance, and chemical resistance since these monomers contain butyl acrylate.

What Does PMMA Look Like?

The name “PMMA” stands for polymethyl methacrylate, which is a clear and colorless substance. However, paints or dyes can be added at any point in the production process to change the color. Because of this PMMA comes in many colors such as clear white, black and many shades of colors that are both see-through and opaque.

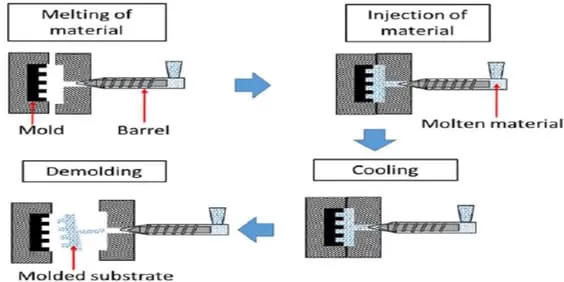

PMMA Injection Molding

PMMA Molding is a very flexible way to make things. In the injection molding process, materials are first melted at high temperatures until they are liquid or molten form. The molten form is then poured into metal molds while being under a lot of pressure and then the mold is left to cool down. After a while it gives you the part of the form you wanted. One popular and effective way to make high-quality plastic parts and samples is through injection molding PMMA.

Advantages of PMMA Molding

PMMA injection molding has a lot of significant advantages over other ways of making things. Here are the most important benefits:

Unmatched Optical Clarity:

PMMA is the most clear of all the thermoplastics that are commonly used. Because it is so easy to see, it is great for places where visibility is important, like in eyeglass lenses, car control panels and digital device screens.

Superior Chemical Resistance:

The chemical resistance of PMMA is very high. It is very resistant to acids, alkalis and alcohols. Because of this property it can be used for things that will be introduced to different chemicals like medical tools and lab equipment.

Exceptional Weatherability:

PMMA injection molding is very resistant to UV rays and bad weather like snow, rain and high temperatures. As a result, it is a great choice for outdoor uses like signs and building parts.

Lightweight and Strong:

The weight-to-strength ratio of PMMA is good. In this way it gives the object the strength it needs without making it too heavy. This type of quality is very important for the aerospace and automotive businesses.

Comparatively Low Processing Temperatures:

PMMA can be made at low temperatures when compared to other thermoplastics. Which reduces the amount of energy needed for production and makes it a more environmentally friendly option.

Versatility in Design and Color Options:

PMMA can be shaped and arranged in a lot of different ways to meet different design needs. It also comes in a huge range of colors which means that the style can be changed a lot for different uses.

Ease of Machining and Finishing:

It will be easy to shape and polish PMMA parts to get the floor finish and functionality you want. This feature lets you make more changes, so it’s worth adding after the first shaping process.

Applications of PMMA Injection Molded Products

Automotive Industry:

Tail lights, control panels, headlight and taillight lenses and many other transparent parts for car interiors.

Lighting Industry:

Diffusers for consistent light spread, lenses for different lighting requirements, and lightweight information plates for eco-friendly light transmission.

Medical Industry:

These include diagnostic tools, medical tool housings and parts that need to be readable and resistant to chemicals.

Consumer Goods:

Displays for digital devices, electronic casings and many clear parts for home appliances.

In Architecture:

It can be used for door and light covers that block out noise, windows, phone booths, and more.

In transportation application:

PMMA is used in cars, trains and doors and windows for other cars.

Choosing the Right PMMA Injection Molding Partner

It is very important to choose the right PMMA injection molding company if you want to get good products and finish the job successfully. When you make your choice, here are some important things to keep in mind:

Expertise with PMMA Molding:

Choose a company with good experience in PMMA molding. They’ll know how to handle the material and optimize the molding process for the best results.

Quality Control Measures:

Look for a company with a strong quality control system. This ensures consistent quality throughout production, reducing the risk of defects and ensuring your final products meet high standards.

Design Help and Prototyping Capabilities:

It is wonderful to have a partner who can assist with planning and creating prototypes. They assist you to make sure that your products design is compatible with the PMMA injection casting process. This will ultimately save you both time and money.

Competitive Pricing and Delivery Times:

It is important to find a balance between cost, quality and delivery time. You should find a trusted partner to keep your project on track who can meet your needs and offer competitive prices without sacrificing quality.

Dedication to Buyer Service:

The key to a good partnership is being able to talk to each other and work together. When looking for PMMA injection molding companies make sure they value open communication, are flexible and are committed to giving you great customer service throughout the project.

Additional Concerns for PMMA Injection Molding

While injection molding PMMA has many advantages here are some more things you might want to think about:

Part Thickness:

PMMA’s resistance decreases with increasing thickness. It is important to work together with your PMMA injection molding companies to achieve the best design for both energy and performance, keeping into consideration the required wall thickness.

Surface Finish:

PMMA can get great floor finishes but to get a high-gloss finish. You might need to do more post-processing steps like grinding. Meet with your partner to talk about possible floor end options and figure out the best way to handle your application.

Material Choice:

PMMA is a flexible material. However types of thermoplastics might work better for different uses that have different needs. If other materials are better for your project, your PMMA injection molding partner should be able to suggest them.

Sustainable Considerations:

PMMA is strong and lasts long so it might be a good choice. PMMA items that are made well can last for years, so you won’t have to replace them as often. As we already said, the fact that PMMA can be worked with at relatively low temperatures also helps to cut down on the energy needed for production.

Partnering with Plasticmold.net for Your PMMA Molding Needs

Are you looking for PMMA injection molding companies? Plasticmold.net is a top-notch PMMA molding product. We have a lot of experience working with PMMA and knowledge to use its unique properties to get unique results. Our hardworking team of professionals will be with you every step of the way, from coming up with the first design ideas to making sure everything is perfect.

This is what units Plasticmold.net aside:

Strong Dedication to Quality:

Quality control is very important to us at every stage of the manufacturing process. This is how we make sure that your PMMA injection-molded parts meet the highest quality standards.

Expertise and Cutting-Edge Technology:

We use state-of-the-art tools and have the knowledge to make PMMA injection molding work best for your needs.

Design and Prototyping Help:

Our team can help you improve the design of your product and make samples so that it is easy to move to production.

Competitive Prices and On-Time Delivery:

We have reasonable prices and work hard to meet your requested response time.

Excellent Customer Service:

It is important for us to have good connections with our customers during your job. We offer helpful customer service and open communication.

Conclusion:

PMMA plastic injection molding offers the best clarity, chemical resistance, weather resistance and design flexibility. This makes it great for many businesses. Partnering with Plasticmold.net gives businesses access to skilled, reliable companies that can help them bring their ideas to life. These companies can get help with design and prototyping, as well as competitive prices and excellent customer service. You can get custom choices from Plasticmold.net for any project, whether you’re making signs, medical devices, auto parts or shopping items. PMMA casting gives you the clarity and quality you need to succeed in today’s tough market.

Ready to Leverage PMMA Injection Molding for Your Business?

We recommend Plasticmold.net if you need a reliable and skilled PMMA molding company. Your project needs will be discussed and the best PMMA choices and the whole process information will be given to you . Allow us to show you how to bring your PMMA-based product ideas to life.

FAQs:

Q. How does Plasticmold.net ensure high quality in PMMA molding?

Ans. Plasticmold.net ensures high quality by strict high-quality management measures at each stage of the manufacturing process, together with materials choice, molding parameters optimization and inspection protocols.

Q. What are the benefits of partnering with Plasticmold.net for PMMA injection molds?

Ans. Partnering with Plasticmold.net presents advantages equivalent to intensive expertise, superior expertise, design and prototyping assistance, aggressive pricing, well-timed supply and distinctive customer support.

Q. How can I get started with Plasticmold.net for my PMMA

Ans. To start with Plasticmold.net, you need to talk about the needs of your project, get professional advice, and work with their team from the first design ideas to the final production.

Q. What are the limitations of PMMA Molds?

Ans. PMMA injection molding could have limitations by way of affect resistance, particularly in thicker sections. Cautious design concerns and materials choice are essential to optimize energy and performance.

Q. What industries generally use PMMA injection molded products?

Ans. Industries like automotive, lighting, medical, shopper items and signage generally use PMMA injection molded products because of its distinctive readability, energy and weatherability.

Q. What are the environmental benefits of PMMA injection molding?

Ans. PMMA molding offers environment benefits like durability, long life and lower energy use during production. Which helps with sustainability by reducing trash and resource use.

Leave a Reply

Want to join the discussion?Feel free to contribute!