INTRO: The World of Collapsible Core Injection Molding

In the world of manufacturing, there exists a fascinating realm where creativity meets precision—the world of injection molding. Among the many techniques that have emerged to meet the diverse needs of modern manufacturing, collapsible core injection molding stands out as a particularly ingenious method. Imagine creating complex hollow parts with undercuts that would make even the most skilled magician raise an eyebrow. This is the kind of magic that collapsible core injection molding brings to the table.

This article dives into the depths of this remarkable technology, which plays a crucial role in producing products that require intricate detail and precision. From automotive components to household items, the applications are as varied as they are interesting. By the end of this article, you’ll not only understand how collapsible core injection molding works but also appreciate its cleverness and utility in manufacturing.

We’ll explore the mechanics behind this technique, the significant advantages it offers, and even sprinkle in some historical context to show how this method has evolved over time. Through examples and expert insights, we’ll illuminate why collapsible core injection molding is a go-to choice for complex mold designs. So, whether you’re a seasoned professional in the field, a budding engineer, or simply a curious mind, prepare to be entertained and informed as we unravel the magic of collapsible core wizardry.

When Molds Take a Bow: The Art of Collapsing

Understanding the Basics

Collapsible core injection molding is a technique that solves the conundrum of creating parts with intricate internal geometries. At its heart, this method involves using a core that can “collapse” or retract, allowing for the easy removal of the finished part from the mold. Imagine needing to remove a ship from a bottle—you can’t just take it out the way it came in without breaking the bottle. Similarly, with traditional injection molding, removing parts with undercuts without damaging them is nearly impossible. Enter the collapsible core, with its ability to fold in on itself, making the impossible quite possible.

This method is especially useful in industries where precision and complexity are non-negotiable. For instance, the automotive industry frequently needs parts with threads, side openings, or other complex features that are best achieved with collapsible cores. By using collapsible cores, manufacturers can achieve complex designs without having to resort to multiple parts or additional assembly processes, which saves both time and money.

Over the years, the development of collapsible core technology has seen significant advancements. Initially, the focus was on simple single-action collapsible cores, which were limited in their capabilities. However, with technological progress, we now have multi-stage collapsible cores that can handle even more complex geometries. This evolution has been driven by the need for more sophisticated products in the market, pushing engineers to innovate and improve collapsible core design continually.

The Mechanics of Collapsible Core Molding

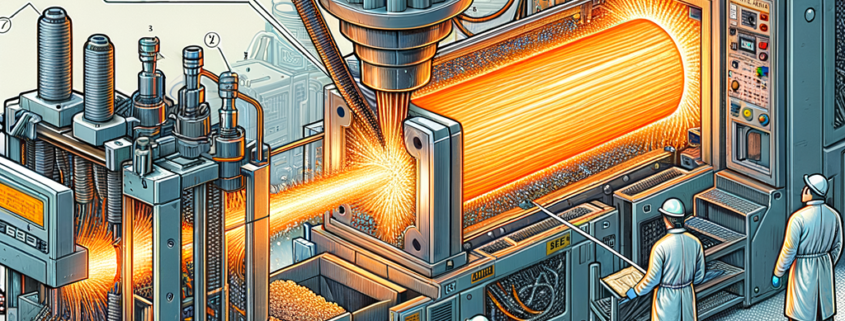

To truly appreciate the magic of collapsible core injection molding, one must delve into its mechanics. The process begins with the design of the core itself, which is typically composed of segments or petals that can contract upon themselves. During the injection phase, the core is fully extended, and molten plastic is injected into the mold cavity that surrounds it. Once the plastic cools and solidifies, the magic happens—the core collapses, releasing the internal features of the molded part without causing any damage.

This collapsing action is achieved through a series of mechanical linkages, springs, or hydraulic systems, depending on the complexity and size of the part. The design of these systems requires a keen understanding of mechanical engineering principles and often involves intricate calculations and simulations. Engineers have to ensure that the core retracts smoothly and that the molded part retains its desired shape and features.

The complexity of collapsible core molding doesn’t end with the core’s design. Selecting the right materials is also crucial. The core must withstand high temperatures and pressures during the molding process, often necessitating the use of specialized alloys or coatings. The art of collapsible core molding lies in balancing these factors to achieve the desired outcome—a beautifully crafted part with intricate internal details.

From Concept to Creation: Crafting with Collapsible Cores

Bringing a design to life with collapsible core injection molding is not just about technical prowess; it’s also an art form. The journey from concept to creation involves several stages, each requiring careful planning and execution. It begins with understanding the product requirements, which inform the design of the collapsible core. Engineers must consider the part’s geometry, material, and the desired production volume to create an efficient and effective mold design.

Once the design is finalized, the focus shifts to tooling—the process of creating the actual collapsible core mold. This involves precision machining and manufacturing techniques to ensure that the core fits perfectly within the mold cavity. Any errors at this stage can lead to defects in the final product, so attention to detail is paramount.

Finally, the actual injection molding process takes place. Here, the magic of collapsible cores is truly on display as the core expands and collapses to release the molded part with ease. Quality control measures are essential at this stage to ensure that each part meets the required specifications. By the end of this process, a once complex and seemingly impossible design has been transformed into a tangible product, thanks to the art and science of collapsible core injection molding.

Applications and Advantages: The Rise of Collapsible Core Molding

Industry Applications: Where Collapsible Cores Shine

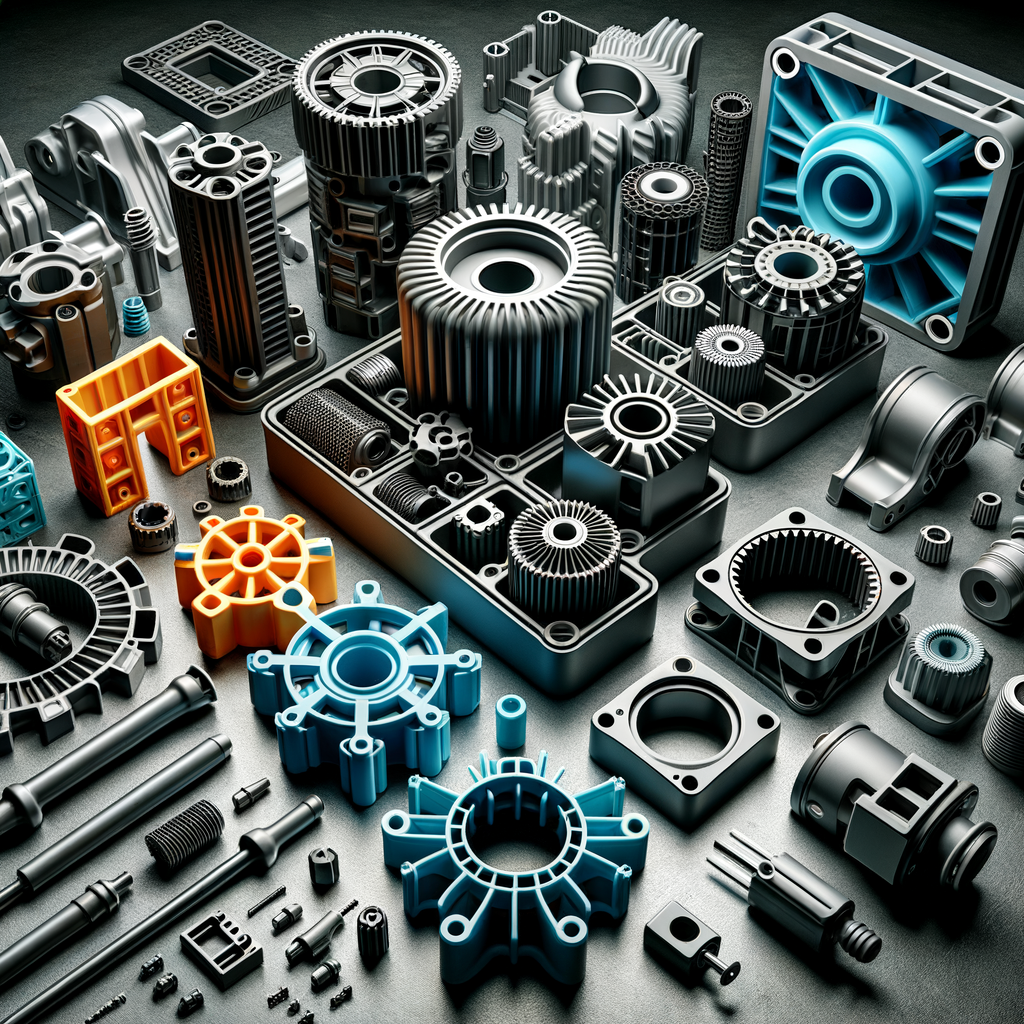

Collapsible core injection molding has found its niche in several industries that demand precision and complexity. One of the primary beneficiaries of this technology is the automotive industry. Here, collapsible cores are used to manufacture components such as air ducts, coolant connectors, and other parts that feature complex internal geometries. These components are integral to modern vehicles and require precise manufacturing to ensure optimal performance.

The medical industry also leverages collapsible core technology for producing parts with intricate shapes and features. Items such as syringe bodies, medical device housings, and other equipment benefit from the precision and reliability that collapsible core molding provides. The ability to create detailed internal threads and undercuts without sacrificing structural integrity is invaluable in medical applications.

Beyond these industries, consumer products also benefit from collapsible core technology. Household items like bottles, caps, and containers often require complex shapes that can be efficiently manufactured using collapsible cores. This method allows designers to push the boundaries of creativity, resulting in products that are both functional and aesthetically pleasing.

Advantages of Collapsible Core Molding: A Game Changer

The rise in popularity of collapsible core injection molding is largely due to the numerous advantages it offers. One of the most significant benefits is the ability to produce parts with complex internal geometries in a single molding process. This capability eliminates the need for secondary machining operations or additional assembly, reducing overall production time and costs.

Another advantage of collapsible core molding is its ability to maintain high precision and consistency across production runs. The collapsing mechanism ensures that each part is molded accurately, with minimal risk of defects. This consistency is crucial in industries such as automotive and medical, where even minor deviations can have serious consequences.

Collapsible core technology also offers flexibility in design. Engineers can create parts with features that would be challenging or impossible to achieve with traditional molding methods. This opens up new possibilities for innovation and allows manufacturers to meet the ever-evolving demands of the market. Ultimately, collapsible core injection molding is a game-changer that has redefined what is possible in the world of manufacturing.

The Art of Problem-Solving: Overcoming Challenges

While collapsible core injection molding offers numerous advantages, it is not without its challenges. Designing and manufacturing collapsible cores requires a deep understanding of mechanics and materials, and any misstep can lead to issues such as core misalignment or part deformation. Engineers must carefully consider factors such as core retraction mechanisms, material selection, and cooling rates to avoid potential pitfalls.

One common challenge in collapsible core molding is ensuring smooth and reliable core collapse. The core must retract seamlessly to avoid damaging the molded part, and achieving this requires precision engineering and high-quality materials. Regular maintenance and inspection of molds are essential to detect wear and tear that could compromise the core’s performance.

Despite these challenges, the potential rewards of collapsible core injection molding make it a worthwhile endeavor. By addressing these issues through careful planning and execution, manufacturers can unlock the full potential of this technology. The result is a manufacturing process that combines creativity, precision, and efficiency to produce complex and innovative products.

The Future of Collapsible Core Injection Molding

Trends and Innovations: What’s Next?

As technology continues to advance, so too does the field of collapsible core injection molding. One of the most exciting trends is the integration of automation and digitalization into the molding process. Automated systems can enhance precision and efficiency, reducing the potential for human error and allowing for greater consistency in production. Digital tools also enable engineers to simulate and optimize core designs, accelerating the development process and reducing costs.

Another area of innovation is the development of new materials and coatings for collapsible cores. Advances in material science are leading to the creation of more durable and heat-resistant materials, which can withstand the harsh conditions of the molding process. These materials not only improve the longevity of collapsible cores but also enable the production of parts with even more intricate features.

Sustainability is also a growing focus in the industry. Manufacturers are exploring ways to reduce waste and energy consumption in the molding process, including the use of recyclable and biodegradable materials. As environmental concerns continue to rise, collapsible core injection molding has the potential to become a key player in creating eco-friendly products.

The Road Ahead: Opportunities and Challenges

As we look to the future, the potential for collapsible core injection molding is vast. The increasing demand for customized and complex products presents opportunities for manufacturers to leverage this technology to meet market needs. By adopting collapsible core techniques, companies can differentiate themselves in a competitive landscape and offer unique solutions to their customers.

However, with these opportunities come challenges. The complexity of collapsible core molding requires skilled engineers and technicians, and there is a continual need for education and training in this specialized field. Additionally, as the technology becomes more widespread, manufacturers must navigate intellectual property considerations and ensure compliance with industry standards and regulations.

Despite these challenges, the future of collapsible core injection molding is bright. Continued investment in research and development will drive further innovation and unlock new possibilities for the technology. As it evolves, collapsible core molding will continue to be a cornerstone of modern manufacturing, enabling the creation of products that push the boundaries of design and functionality.

Embracing the Magic: A Call to Action

The magic of collapsible core injection molding lies in its ability to turn complex ideas into reality. As we embrace the future, it is essential for manufacturers, engineers, and innovators to recognize the potential of this technology and harness its power to drive progress. By investing in education, research, and collaboration, we can unlock new opportunities and overcome the challenges that lie ahead.

For those in the manufacturing industry, now is the time to explore the possibilities of collapsible core injection molding. Whether you are looking to optimize existing processes, innovate new products, or reduce environmental impact, collapsible core technology offers a path forward. By embracing this magic, we can create a more efficient, sustainable, and innovative future for the world of manufacturing.

OUTRO: The Magic Continues

In the world of manufacturing, collapsible core injection molding stands as a testament to human ingenuity and creativity. This remarkable technology has transformed the way we approach complex designs, offering a solution that combines precision, efficiency, and artistry. Through the magic of collapsible cores, manufacturers can bring even the most intricate ideas to life, paving the way for innovation and progress.

As we have explored in this article, the journey of collapsible core injection molding is one of continuous evolution. From its early beginnings to its current state, this technology has adapted and grown, driven by the demands of an ever-changing market. The possibilities it offers are vast, and its applications are as diverse as the industries it serves. Whether in automotive, medical, consumer products, or beyond, collapsible core molding has proven itself as an invaluable tool in the arsenal of modern manufacturing.

The future holds even more promise for collapsible core injection molding. As new materials, technologies, and methodologies emerge, the potential for this technology to revolutionize industries is immense. By embracing the challenges and opportunities ahead, we can unlock new levels of creativity and innovation, shaping a future where the magic of collapsible cores continues to inspire and amaze.

In conclusion, collapsible core injection molding is more than just a manufacturing technique; it is a journey of exploration and discovery. As we continue to unfold the magic of collapsible core wizardry, let us celebrate the artistry, precision, and ingenuity that define this remarkable process. Whether you are a seasoned professional or a curious enthusiast, the world of collapsible core injection molding invites you to join in the adventure and contribute to the magic that shapes our world.