Insert molding

What is Insert Molding

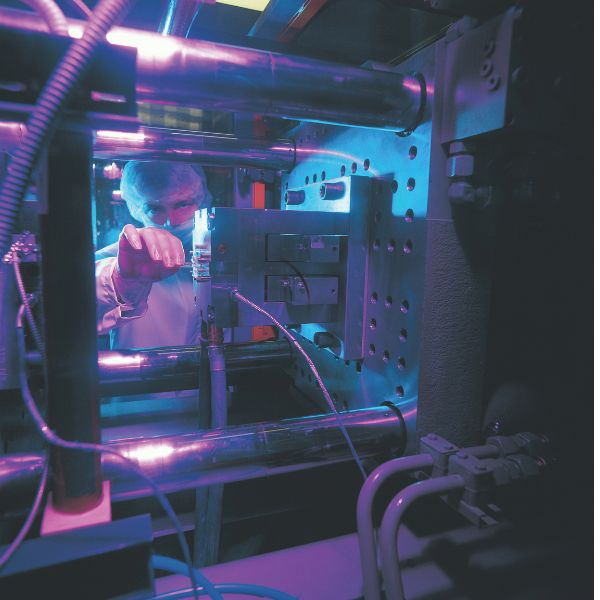

Insert molding, also called insert injection molding, or overmolding, involves placing a pre-formed object in a mold and covering it with plastic or another material to create a finished product. This method produces auto parts, medical devices, and consumer goods.

We will discuss insert injection molding’s benefits, materials, steps, applications, manufacturer issues, and future.

Advantages of Insert Molding

Insert molding has manufacturing benefits worth considering. This is one of its best features because it reduces assembly costs. Manufacturers can reduce assembly steps by combining two or more parts into one. This eliminates extra work and assembly errors.

Insert molding improves product reliability. The insert is enclosed in plastic or another material, making it less likely to fall out or be damaged. Better, the item may last longer and have fewer warranty claims.

Finally, insert injection molding allows more design options. Designers can create more complex shapes and features by combining multiple materials and parts into a component. Some think this will inspire more creative and attractive products.

Different Types of Inserts for Injection Molding

The form and material composition of inserts used in insert injection molding can differ. Materials including metal, ceramic, composite, and plastic are frequently used. Ceramic inserts give resilience to extreme temperatures, while metal inserts offer remarkable strength and endurance. Plastic inserts can be utilized for applications that require low weight and cost whereas composite inserts blend various materials to attain certain qualities.

The final part’s intended performance qualities, budgetary constraints, and compatibility with the plastic material all play a role in the insert selection process. Manufacturers have to consider these aspects carefully in order to select the best inserts for their particular use.

Benefits and Uses of Injection Molding Inserts

Compared to conventional injection molding methods, insert injection molding has a number of benefits. Parts can be made stronger and more capable of withstanding greater loads and strains by adding inserts. This creates options for smaller walls and lightweight designs, which lower total costs and material consumption.

Moreover, insert injection molding provides more design freedom by facilitating the integration of intricate geometries like internal features and undercuts. Multiple materials and components can be combined into a single part to streamline assembly procedures and enhance overall product functionality.

Insert injection molding is very beneficial to the automotive sector. Manufacturers are able to develop lightweight components with superior structural integrity by combini

ng plastic overmolding with metal inserts. The aerospace, consumer goods, medical, and electronics sectors all use insert injection molding to produce complex parts with higher performance and dependability.

Issues & Things to Think About for Insert Injection Molding

Even while insert injection molding has many benefits, there are certain particular difficulties. The mold’s design is one important factor to take into account. An effective flow of molten plastic around the inserts is ensured by a well-designed mold, preventing problems such as inadequate encapsulation or air entrapment.

Another important consideration is choosing appropriate materials for the plastic overmolding and inserts. It is necessary to guarantee the two materials’ compatibility in order to create a solid bond and avoid delamination. Using specific materials made for insert molding or applying surface treatments can help reduce adhesion and bonding problems.

Insert injection molding is a process where quality control is essential. Inspection methods guarantee that the finished components fulfill strict quality requirements. Examples of these methods include visual inspection, dimensional checks, and non-destructive testing. In order to ensure consistency and dependability in their products, manufacturers need to put strong quality control procedures in place.

Prospective Developments and Advancements in Insert Injection Molding

Further breakthroughs in insert injection molding are anticipated as technology progresses. Modern simulation tools and additive manufacturing techniques are being included into mold design and manufacturing processes. These developments save lead times and enhance part quality by enabling more accurate and effective mold designs.

Robotics and automation are also becoming more and more important in insert injection molding. Insert insertion can be handled by automated systems, which minimizes manual effort and increases production efficiency. Robotics can help with the exact placement of inserts inside the mold, guaranteeing best alignment and lowering the possibility of mistakes.

Another area of interest for insert injection molding is material innovation. Researchers are creating new materials with enhanced adhesive qualities that will enable inserts and plastic components to adhere more firmly and consistently. Furthermore, developments in composite materials present the chance to achieve even greater strength-to-weight ratios and personalized characteristics.

New sectors and applications are realizing insert injection molding’s potential. Industries including robotics, telecommunications, and renewable energy are using this technology to develop customized parts that fit their specific needs. More industries are likely to investigate insert injection molding’s advantages and incorporate it into their manufacturing processes as knowledge of the technology grows.

Presenting PlasticMold.net, the best answer to all of your plastic molding requirements! A Chinese mold manufacturer called Sincere Tech provides a large selection of excellent plastic molds that are ideal for all of your manufacturing needs. We have established ourselves as a dependable and trustworthy source for all your plastic molding needs thanks to our years of experience in the field.

With the help of our user-friendly interface, you can quickly peruse our wide selection of plastic mold from our China mold manufacturer. We have a mold for any need, from household goods to vehicle parts. Our team of professionals works nonstop to ensure that you always have access to the greatest products available by updating our inventory with the newest and most cutting-edge designs.

At PlasticMold.net, we’re dedicated to giving our clients the best possible support and products. Since every customer has different demands, we provide a variety of customization choices to make sure you get exactly what you need. You can always count on our team of experts to help you choose the ideal mold for your unique needs.

We not only provide excellent products and services, but we also have affordable prices and quick delivery. Since we are aware that production takes time, we put forth great effort to guarantee that your orders are delivered on schedule and in flawless shape.

Why then wait? Get the best plastic molding solutions by contacting us right now if you need mold suppliers for insert injection molding or any other custom molding project. We are certain that you will find everything you need to advance your production with our wide range of premium molds, first-rate customer support, and affordable prices.

Challenges in Insert Molding

Insert molding has many benefits, but manufacturers must overcome some issues before using it. One of the hardest problems to solve is part design concerns. The insert’s design must be carefully considered to ensure proper placement, shape, performance, and appearance.

Material selection causes other issues. Consider how well the material will work, how much it will cost, and how well it will work with the other components when choosing it.

Another issue with insert molding is that inserts must be placed and oriented. Proper positioning and orientation are needed to fully encase the insert in plastic or other material and make it work properly.

Lastly, insert plastic molding tools and molds are difficult to maintain. Complex molds are used in this process and must be regularly checked and repaired to ensure high-quality parts.

Future of Insert Molding

All the new technologies and materials coming out soon make insert molding look promising. New materials that work better and are greener are a priority.

Another focus is insert molding automation and robotics. This will increase production speed, quality, and consistency.

Finally, the manufacturing industry is becoming more environmentally conscious. Insert injection molding reduces waste and extends product life. Consolidating several parts into one reduces assembly steps and materials.

Insert molding also benefits designers and manufacturers during the manufacturing process. Insert molding increases design flexibility, lowers assembly costs, and improves product reliability. Put different materials and parts into one segment.

Materials, technology, and sustainability are improving, so insert molding has a bright future. Manufacturers face challenges when using insert molding, but it has a bright future. Insert molding will remain important in manufacturing for many years for these reasons.

Contact us if you need mold suppliers for your insert molding project.

In summary

By fusing the advantages of conventional injection molding with the incorporation of pre-placed inserts, insert injection molding is completely changing the manufacturing industry. Many benefits come with the procedure, such as increased usefulness, flexible design, and stronger parts. Insert injection molding is already beneficial to the automobile, electronics, medical device, and aerospace industries.

To guarantee a successful deployment, however, issues including material selection, quality control, and mold design factors must be properly addressed. Insert injection molding is well-positioned to continue developing and pushing the limits of what is feasible in contemporary production thanks to developments in material science, automation, mold design, and growing applications.

It’s evident that insert injection molding will continue to lead the way in innovation going forward, giving producers the ability to enhance their goods’ performance, efficiency, and competitive edge. Businesses may stay ahead of the curve and provide intricate, high-quality parts that satisfy the needs of various markets and industries by adopting this cutting-edge technology.

Leave a Reply

Want to join the discussion?Feel free to contribute!