Glass-filled nylon Injection molding is a very important process in present-day manufacturing. The process is an integration of the plastics that are flexible and strong like glass fibres, giving rise to lightweight, strong, and accurate parts. High-stress and high-temperature components. A considerable number of industries can utilize glass-filled nylon injection molding to produce high-stress and high-temperature components with a consistent quality.

Manufacturers use this material since it enables them to produce in large volumes without compromising on performance. In the modern day, automotive, electronics, and industrial processes require this process to give them strong, reliable, and cost-effective components.

What is Glass Filled Nylon?

Polyamide reinforced material is glass-filled nylon. Nylon is mixed with small glass fibres to transform it into one with improved mechanical properties. The injection moulding of glass-filled nylon is used, which creates a part that would be harder, stronger and heat resistant as compared to plain nylon.

The inclusion of the glass fibres reduces the warping and shrinkage of the cooling process. It ensures the final product is of the right size, and this is vital in the fields of industry and automobiles.

The principal properties of the glass-filled nylon are:

- High tensile strength

- High levels of dimensional stability.

- Hemolytic and chemolithic resistance.

- Light in weight compared to metals.

The production of glass-filled nylon injection moulding guarantees not only the durability of the parts but also makes them cost-effective when it comes to mass production.

Physical, Chemical, and Mechanical Properties

The article titled Injection moulding glass-filled nylon is a mixture of nylon that has a high degree of flexibility and glass fibres, which have high strength and endow unique characteristics. Knowledge of these assists in creating credible components.

Physical Properties

- Density: 1.2 -1.35 g/cm 3, which is slightly heavier than unfilled nylon.

- Water Absorption: 1-1.5% (30% glass-filled) falls as the content of fibres is raised.

- Thermal Expansion: Low dimensional stability coefficient (1535 µm/m -C)

Chemical Properties

- Resistance: High towards fuels, oils and most of the chemicals.

- Flammability: A V-2 to V-0, depending on grade.

- Corrosion: Not corrodible like metals, perfect in unfavorable environments.

Mechanical Properties

- Tensile Strength: 120-180 Mpa and it depends on the fibre content.

- Flexural Strength: 180–250 MPa.

- Impact Resistance: Medium, and reducing with an increase in fibre content.

- Stiffness: Stiffness is high (5 8Gpa), which offers stiff load-bearing components.

- Wear Resistance: It is superior in gears, bearings and moving elements.

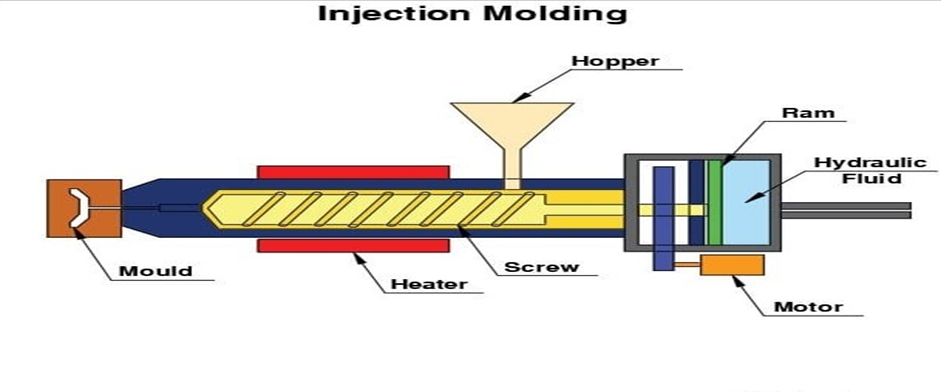

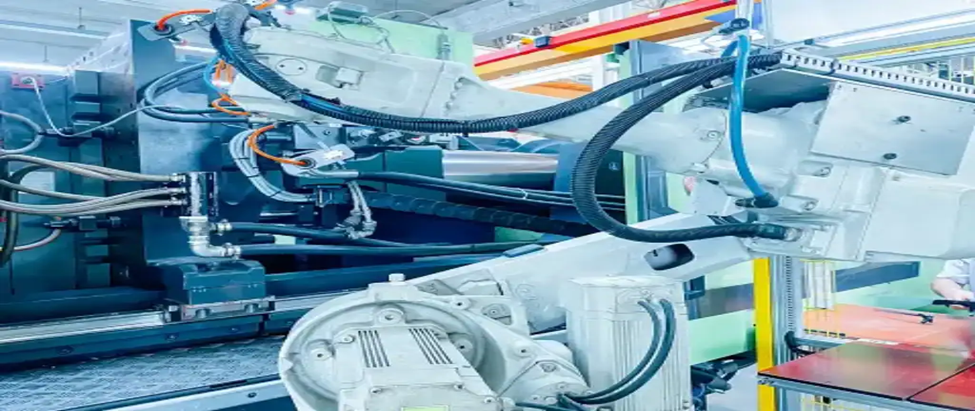

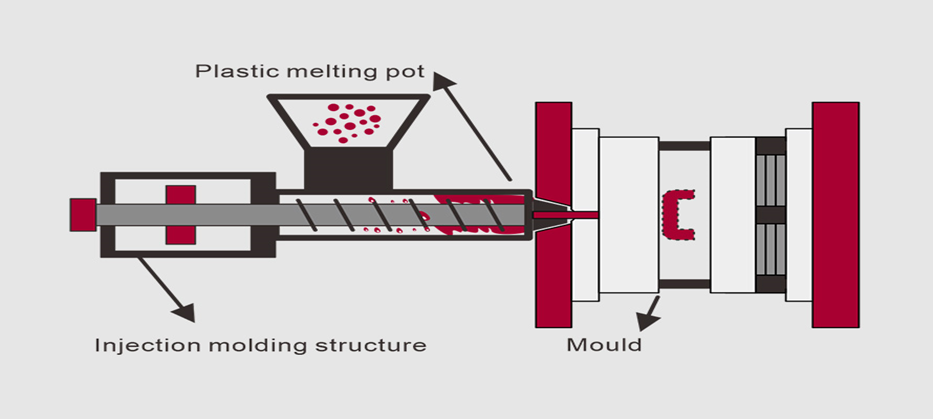

The Injection Molding Process

Glass-filled nylon injection moulding is done by melting the composite material and then injecting it under high pressure into a mould. The procedure is divisible into several steps:

- Preparation of the material: The composition of the proper quantity of glass fibre and Nylon pellets is mixed.

- Melting and injection: The material is heated until melted, then it is forced through a mold.

- Cooling: This is a solidification process whereby the fibres are fixed.

- Ejection and finishing: The rudiment of the solid is taken out of the mould and is likely to be trimmed or polished.

The glass fibres in the injection molding glass filled nylon assist the part not to lose its shape and strength once it is cooled down. This is particularly needed in tightly toleranced and very complex designs.

Advantages of Utilizing Glass-Filled Nylon

The material glass-filled nylon injection molding offers several benefits in comparison to a conventional material:

- Strength and durability: Tensile and flexural strength are achieved with the use of glass fibre.

- Heat resistance: This implies that the components can resist the high temperatures without deforming.

- Dimensional accuracy: The lesser shrinkage is an assurance of the resemblance of different batches.

- Lightweight: The material is strong, but upon being made lightweight, it becomes more efficient in automotive and aerospace uses.

- Cost efficiency: Shorter production time and reduced waste would lower the costs.

On the whole, the term injection moulding glass-filled nylon enables makers of high-performance parts to create their parts efficiently and address the needs of the modern industry.

Glass Filled Nylon Processing Tips

When injecting glass-filled nylon, it is important to pay attention to the behavior of the material and the settings of the machine. Flow, cooling and thermal properties are altered by the presence of glass fibers. When the correct instructions are followed, the glass-filled nylon injection molding could result in robust, accurat,e and flawless components.

Material Preparation

Glass-filled nylon is easily used as a moisture-absorbing material. Wet material may lead to bubbles, voids and bad surface finish. Dry the material at 80–100 °C in 46 hours. Make sure that the glass fibres are not clumped together in the nylon in order to achieve uniform strength.

Melt Temperature

Keep recommended nylon grade melt temperature:

- PA6: 250–270°C

- PA66: 280–300°C

Excessive temperature may ruin the nylon and spoil fibers whereas excessively low temperature causes poor flow and inadequate filling in injection moulding glass-filled nylon.

Injection Pressure and Speed

Moderate injection rate and pressure: 70 -120 Mpa is normal. Quick injection can deform fibres and cause stress within fibres. Appropriate speed not only allows smooth flow but also produces consistent fibre orientation, leading to stronger parts.

Mold Temperature

Surface finish and dimensional accuracy depend on the temperature of the mould. Maintain 80–100°C. The low temperatures of the mould can produce warping and sink marks, whereas high temperatures enhance the flow and reduce the cycle time.

Cooling Time

Wall thickness should be equal to the cooling time. Makes it too short and it warps, too long and it makes it less efficient. Proper cooling channels assist in ensuring that there is uniform cooling and accurate dimensions in the glass-filled nylon injection moulding.

This is what happens to it upon being ejected and post-processing

Use 1 -2 degrees draft angles to achieve smooth ejection. It is important to avoid too much force of ejection capable of pulling fibres or snapping part. After processing, there could be trimming, polishing or annealing to resolve internal stress.

Fiber Content Consideration

The content of glass fiber is usually 30 50% in weight. An increase in fiber content enhances strength, stiffness and heat tolerance, but decreases impact toughness. Control parameters of processing to avoid defects by adjusting to fiber content.

Potential Glass-Filled Nylon Substitutes

Though, the glass-filled nylon with an injection moulding is strong and durable, sometimes there are better materials to use in certain requirements.

- Unfilled Nylon (PA6/PA66): Nylon is lightweight, cheaper and simpler to work with, and it is recommended in low-stress work, but is not as stiff as glass-filled nylon.

- Polycarbonate (PC): Impact strength and heat resistance are high, and stiffness is less than that of glass-filled nylon injection molding.

- Polyphenylene Sulfide (PPS): This is very strong in both chemical and heat resistance and can be used in high temperature applications at the expense of.

- Acetal (POM): Dimensional stability, low friction and weak in heat resistance and stiffness.

- Fiber-Reinforced Composites: Carbon or aramid reinforcing fibres are stronger, stiffer, more complicated and costly to process.

Glass Filled Nylon Properties

The glass-filled nylon in the form of injection molding is preferred due to the good mechanical and thermal properties it has, which qualify it to withstand the demanding nature of the applications. The addition of nylon with glass fibres increases the strength, rigidity, and dimensional stability of the material. Here are the main properties:

High Tensile Strength

Nylon-containing glasses are resistant to high pulling and stretching forces. This renders glass-filled nylon injection moulding suitable for structural components in automotive and industrial applications.

Excellent Heat Resistance

Glass fibers enhance thermal stability so that parts can be strong at high temperatures. This is crucial to the elements that are exposed to engine heat or electronic equipment.

Dimensional Stability

The glass fibers minimize the contraction and deformation during cooling. The process of Injection molding glass-filled nylon creates the parts that do not lose their shape and accurate measurements even in complex designs.

Improved Stiffness

Glass-filled nylon is stiffer than normal nylon and is not likely to bend when under pressure. This suits it with gears, brackets and mechanical housings.

Fashion and Friction Resistance

Glass fibers also increase the abrasion resistance, thus decreasing wear on the moving parts. The service life of components is prolonged by using the glass-filled nylon injection molding which is especially applicable in high-friction environments.

Lightweight

Though it is powerful, glass-filled nylon is significantly lighter than metal products, hence it is used in automotive components, aerospace, and electronic products where weight reduction is important.

Chemical Resistance

Nylon is glass-filled and can withstand oils, fuels and most chemicals and is thus appropriate in harsh environments. This will guarantee durability in industry or automotive parts.

Types of Glass-Filled Nylon

Glass filled nylon has several types each intended to be used in a particular manner in injection molding glass filled nylon and glass filled nylon injection molding.

PA6 with Glass Fill

Nylon 6 (PA6) that is reinforced with glass fibers is strong and stiff with wear resistance. It is mostly applied in industrial and car parts.

PA66 with Glass Fill

PA66 (Nylon 66) is more heat-resistant and has slightly better mechanical properties than PA6. It will be perfect in high-temperature applications such as engine components or electric housings.

PA6/PA66 Blends with Glass Fill

Blends combine the hardness of PA6 and the heat defiance of PA6,6, which gives a balance between strength, stiffness and dimensional stability.

Specialized Grades

Glass-filled nylons sometimes contain lubricants, flame-resistant materials or UV stabilizers to be used in electronics, outdoor parts, or safety gear.

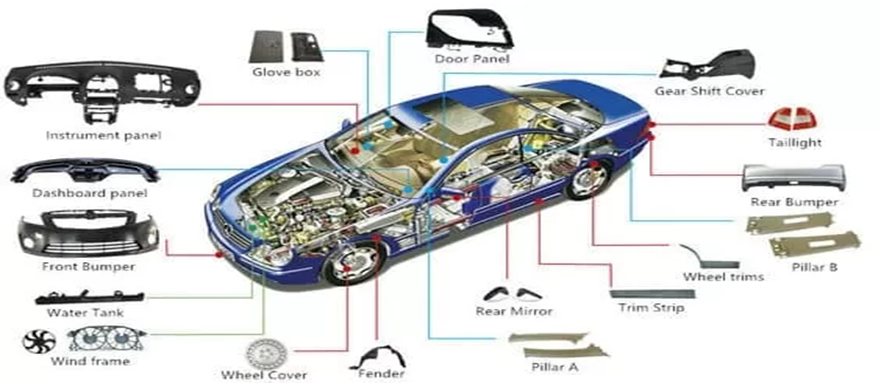

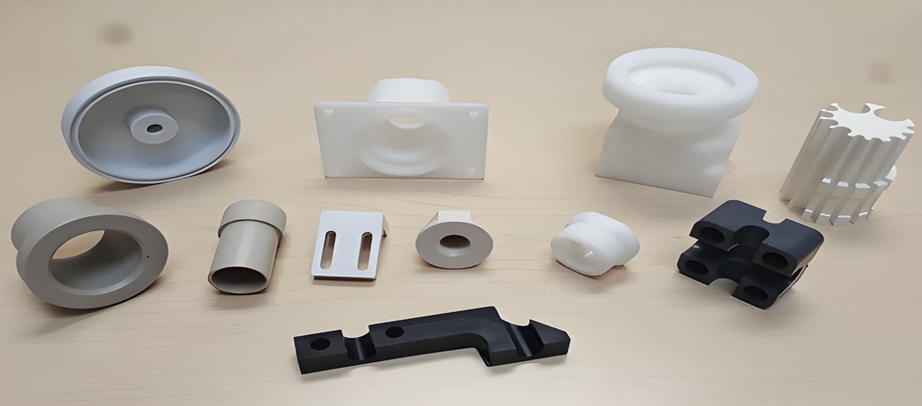

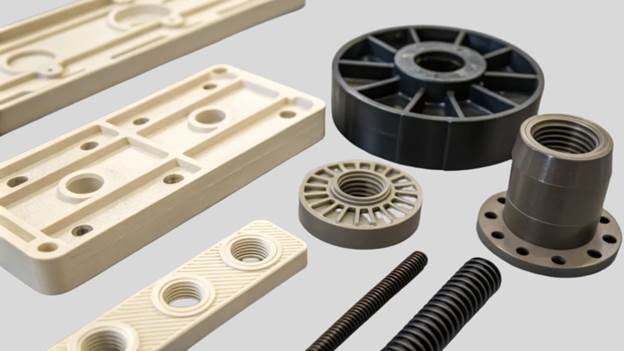

Glass-Filled Nylon Injection Molding Uses

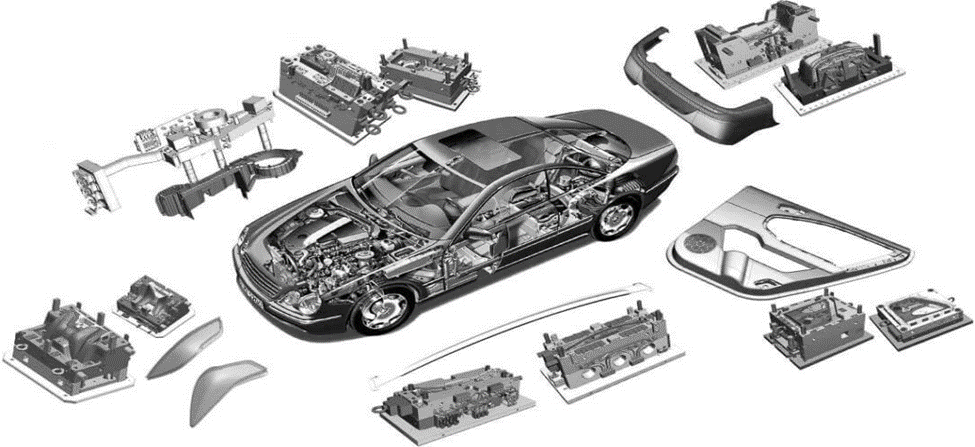

Glass-filled nylon injection molding is finding a lot of applications in a wide range of industries because of its strength, heat resistance and accuracy. Examples of its common uses are:

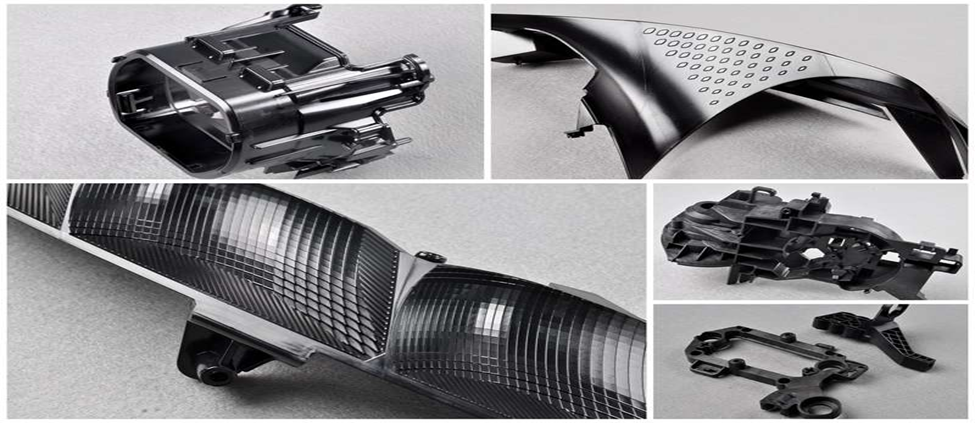

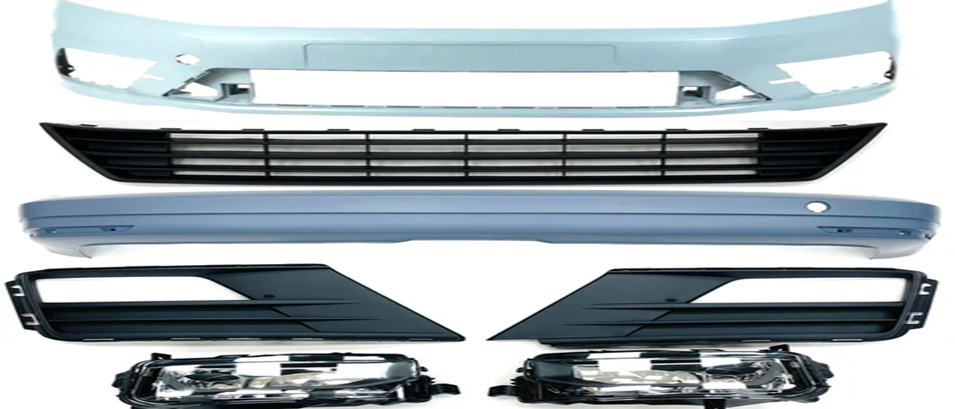

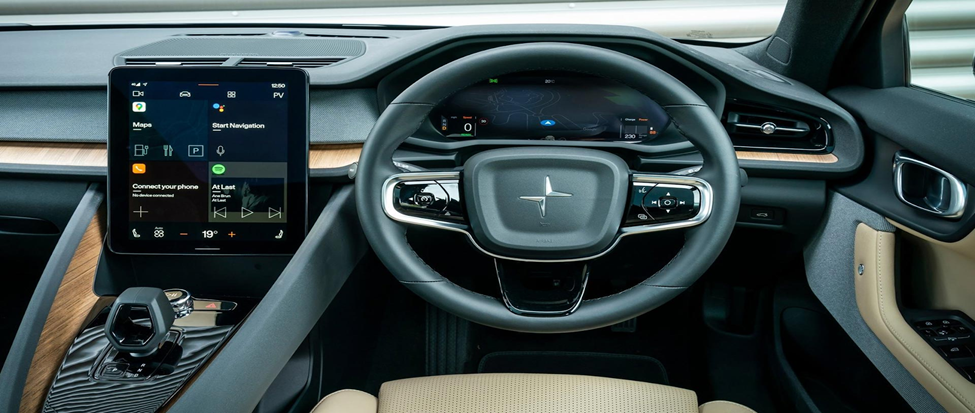

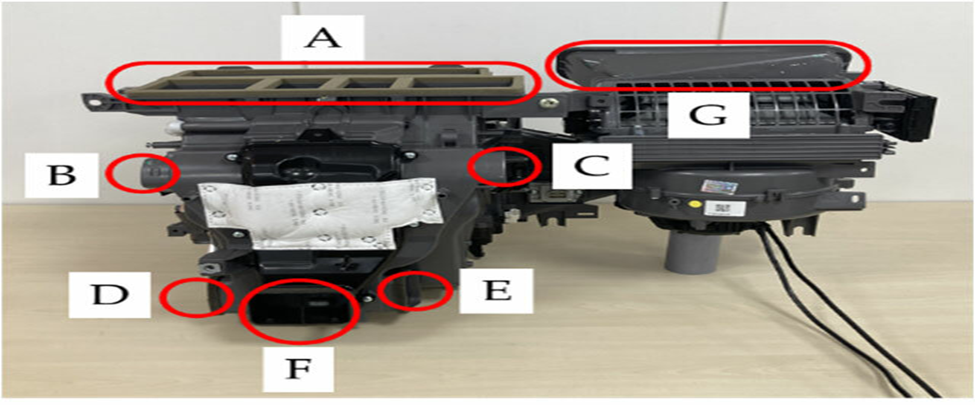

Automotive

- Gears and bushings

- Brackets and housings

- Clips and fasteners

Electronics

- Electrical connectors

- Switch housings

- Insulating components

Industrial Machinery

- Wear-resistant parts

- Machinery functional parts.

Consumer Products

- Appliance components

- Sporting equipment

- Durable casings

Applying nylon filled with glass in injection molding in these applications will guarantee good long and reliable work even in difficult conditions.

Glass Filled Nylon Injection Molding Design Guidelines

Components meant to be used in a glass filled nylon injection molding have to be designed with much care to ensure that the components are as strong as possible, precise and at the same time durable.

Wall Thickness

- Havea similar wall thickness to avoid sinking and warping.

- Most glass-filled nylon parts should be recommended with a thickness of 2-5 m, depending on the load requirement.

Very fine sections should be avoided as they can lead to weakening of the fiber structure and thick sections should be avoided as they can lead to uneven cooling and internal stresses.

Corner Radii

- Sharp corners should be replaced by rounded ones.

- Stress concentration is minimized with a radius of between 0.5 and 1.5 times the wall thickness.

- Injection molding glass filled nylon has sharp edges that may cause fiber breakages or cracks.

Rib Design

- Ribs do not add material, and they make the product stiffer.

- Maintenance of ribs 50 to 60% of the adjacent wall.

- The height of the ribs must not be more than 3 times the thickness of the wall; otherwise, sink marks and warpage will occur.

Correct rib design enhances strength and dimensional stability in nylon injection molding that is filled with glass.

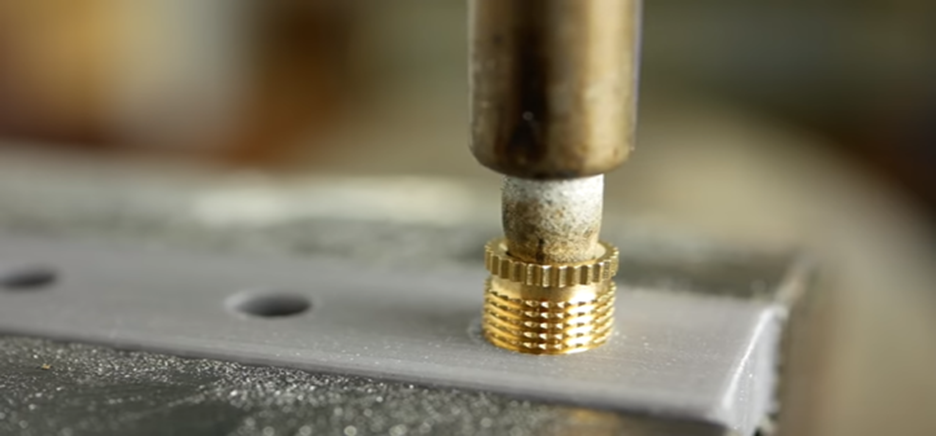

Boss Design

- The screw attachments are done with bosses.

- Have a ratio of thickness 1:1 of the wall and fillets on the bottom.

Long thin bosses are to be avoided because they can become warped during curing with glasses filled nylon injection moulding.

Draft Angles

- Never leave out a draft angle so that they can easily be ejected from the mould.

- Vertical walls should have a minimum draft of 1-2 degrees on each side.

Scratches, deformation, of fiber pull-out during demolding can be avoided in the process of proper drafting.

Orientation of Fiber Flexibility.

- The glass fibers in injection molding glass filled nylon are so oriented that they move down the direction of the flow when injecting.

- Get design details such that the paths of stress are parallel and normal to the fiber to achieve maximum strength.

Features leading to fibers bunching or misaligning should be avoided as they may result in a decrease in mechanical performance.

Shrinkage and Warping

Glass-filled nylon also shrinks less compared with unfilled nylon, yet unequal thickness of the wall may lead to warping.

Varying wall thickness, ribs, and inadequate cooling channels should be used to ensure minimum dimensional variation.

Surface Finish

- This may cause the surface to be a little bit rougher because of the presence of glass fibers.

- Apply polished molds or post-processing in case a smooth finish is very important.

- Do not polish too much, so as not to disorient fibers in glass filled nylon injection molding.

Popular Complications and Remedies

Although the injection molded glass filled nylon is effective, it presents some challenges:

- Fiber rupture: happens when shearing is excessive in mixing.

- Remedy: Adjust mixing time and speed of the solution screws.

- Distortion of parts: parts can be distorted due to uneven cooling.

- Remedy: Fine-tune the temperature of the mould, and mould design.

- Roughness of surfaces: fibres can provide uneven finishes.

- Solution: Polish moulds and processes.

- Water intake: nylon is a water absorber, and this influences the quality.

- Solution: Before molding, the materials should be pre-dried.

The manufacturers would be capable of exploiting the maximum of glass-filled nylon by addressing these issues.

Considerations of the Environment and Cost

In certain instances, where metals are used, glass filled nylon injection moulding is more environmentally friendly:

- Less energy use: lighter materials will minimize energy use in manufacturing.

- Less material waste: scrap is minimized by accurate moulding.

- Extended product life: durable parts require fewer replacements hence low environmental impact.

There is also the advantage of lowering costs through increased speed and decreased wastes, which means that injection molding glass filled nylon will be favorable choice in the large-scale production.

Best Practices by the Manufacturers

The best practices to make the use of glass filled nylon injection molding successful include:

- Wipe off the pre-dry materials to avoid moisture-related defects of moisture.

- Even fiber distribution Use appropriate screw design.

- Maximize the temperature of moulds and injection rate.

- Check the cooling of the monitor to ensure there is no warping.

- Surfaces of high-quality moulds should be used.

It is by following these practices that high-quality and consistent parts with excellent performance will be achieved.

Future Trends

The application of glass filled nylon injection moulding is increasing because of:

- More need for automotive lightweight parts.

- Consumer electronics are of high-performance. Heat-resistant components that are used in industrial automation.

It is still being researched to be able to align the fiber better, lower the cycle time, and increase the time in which this material can be recycled, thus it can be even more beneficial in the future.

About Sincere Tech

Website: https://plas.co

Sincere Tech is a reputable firm that offers services of plastic injection moulding. We are specialized in glass filled nylon injection molding.

What We Do

Our strong and accurate parts are used in automotive, electronic, and industrial applications. Each element is inspected to comply with the standards of high quality.

Why Choose Us

- We produce long-lasting and high-quality parts.

- Our personnel are highly qualified and professional.

- We offer cost-effective and quick solutions.

- We have given attention to customer satisfaction.

At Sincere Tech, we will provide quality products that satisfy you.

Conclusion

Glass-filled nylon injection molding and injection molding glass filled nylon injection moulding are crucial processes in present-day manufacturing. These are strong, heat-resistant, dimensionally stable and cost-effective. Inan automobile, electronic or industrial machine, glass-filled nylon can be used to ensure high-performing, durable and reliable components. Manufacturers have been able to deliver high-quality and consistent results by using best practices, design, and process control. Glass-filled nylon injection molding has been one of the most viable and effective solutions to industry in terms of strength, lightweight and low cost.