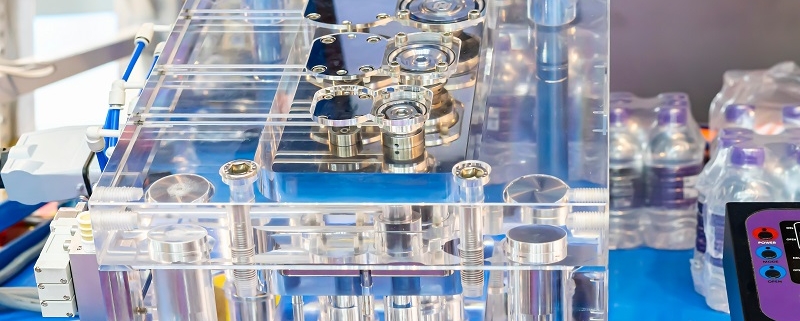

Today, time is of the essence in the fast-paced manufacturing world, acrylic injection molding provides precision, durability, and efficiency at the highest level possible. As the common name suggests, acrylic (or polymethyl methacrylate (PMMA)) is highly valued for its outstanding transparency, strength, and toughness, and it has become a staple material in use by the automotive, aerospace, medical, and consumer electronics industries. With acrylic injection molding, superior optical properties, weather resistance, and mechanical strength of high precision components can be molded consistently. From automotive light covers and medical enclosures right down to high-end optical lenses and even custom signage, molded acrylic products are changing modern innovation. Yet, the process can be mastered only with experience dealing with material behaviour, mold design, and process optimization, since the process has challenges that must be worked out such as brittleness, shrinkage, and cooling time.

In this article, we will discuss the intricacies of the acrylic injection molding process, with its process, application, design principles, advantages and also the future trends. The application of AI driven molding as well as the use of sustainable materials and 3D printing molds is rapidly shaping the future of acrylic manufacturing to new areas of application when it comes to high performance plastic solutions.

Understanding Acrylic Injection Molding

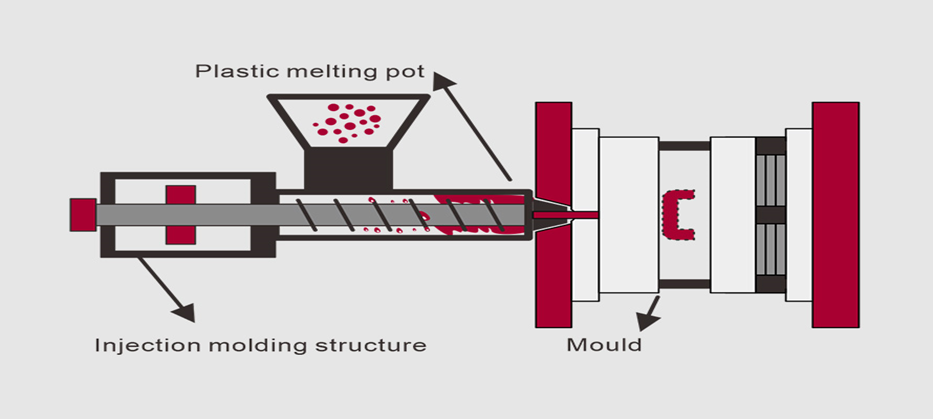

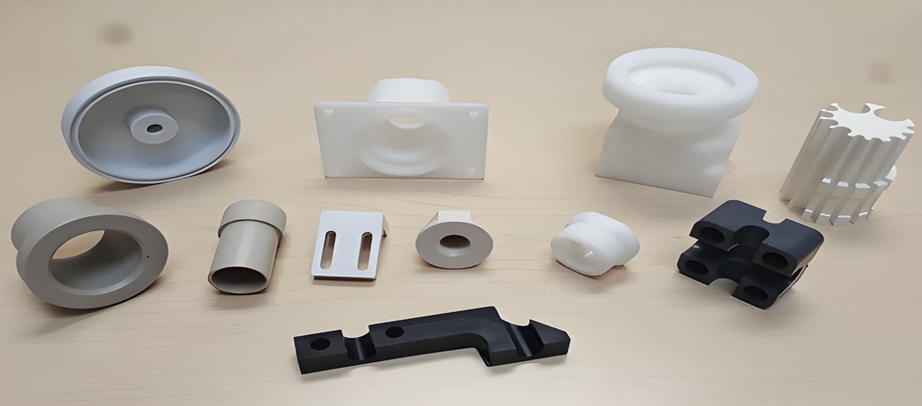

Acrylic injection molding is the process of heating acrylic resin to a molten state using heat, and then under high pressure injecting it into a mold making the parts. For high volume production, the process is widely used for achieved consistency of design, accuracy and quality.

Key Stages of Acrylic Molding

Material Preparation: The moisture in acrylic pellets is removed so that the pellets dry out and can have defect-free molding.

Melting and Injection: In the second case, the pellets are introduced into a mold cavity where they are heated to 200–250°C.

Cooling and Solidification: Once the acrylic has taken shape, the mold is cooled.

Ejection of the Product: The mold is opened and the finished part is released.

Post-Processing: It is not the shape of the product but rather surface finishing, polishing, or coating that improves the appearance and functionality of the product.

Various Properties of Acrylic

We mentioned some important characteristics of acrylic include abrasion resistance and impact strength previously. In this part, we’ll delve into its properties so that their nature is not a puzzler for a person who is interested in getting to know why acrylic is so useful in manufacturing.

General Properties of Acrylic

Density: 1.19 g/cm³

Rockwell Hardness: M 102

Water Absorption: 0.2%

Flammability Rating: UL94 HB, Class 3 (BS 476 Part 7)

This acrylic is lightweight but it is a very strong plastic. Good impact resistance over traditional glass allows it to be less likely to shatter. Furthermore, acrylic is a poor thermal conductor material, thus it can be used as an excellent thermal insulator material. Acrylic is not only heat resistant but has protection against UV rays, which means that it would be an appropriate choice for application outdoors where one is subject to exposure to sunlight.

Optical Properties of Acrylic

Light Transmission: Over 92%

Refractive Index: 1.49

Acrylic’s clarity is one of the primary reasons why it is used so widely in optical applications. In terms of transparency to light, it transmits over 92 percent of visible light, which matches that of excellent glass. Used in mechanical or vapor polishing techniques, it becomes polished like crystals and becomes a good pick for the lens, light guide, display panel. High clarity acrylics are the popular acrylic brands like Perspex, Rohm Plexiglas, etc.

Mechanical Properties of Acrylic

Tensile Strength: Approximately 8,000 psi

Tensile Modulus: 350,000 – 500,000 psi

Flexural Modulus: Similar to the tensile modulus

Acrylic is also a strong and rigid thermoplastic that can hold a great amount of mechanical stress. Its tensile strength is about 8,000 psi, so it would take 8,000 pounds per square inch to crack the material. Further value of its high modulus values also indicates that acrylic can still be structurally stable under bending and stretching forces. It is also water resistant and UV resistant and this makes it a better choice for outdoor signs, protective shields, and automotive components.

Thermal Properties of Acrylic

Minimum Service Temperature: -40°C

Maximum Service Temperature: 80°C

Softening Point: Above 110°C

Linear Expansion Rate: 7.7 × 10⁻⁵

Acrylic has a melting point from 130° C to 140° C is its maximum operating temperature from 65° C to 93° C. Thus, it can endure moderately high temperatures but deformation or softening will occur when subjected to excessive heat. Due to its low heat conductivity, acrylic functions as an efficient thermal insulator. It is also easily moldable when hot and used as a thermoformed material, as well as an injection molding, and fabrication process material.

Applications of Acrylic Injection Molding

Acrylic injection molding is a familiar manufacturing method of producing fine, durable, and high quality components in various industries. Manufacturers inject molten acrylic into a mold to create parts that are both highly clear and strong, as well as resistant to the weather. Some key applications of acrylic molding are given below.

1. Optical Components

Since acrylic has high light transmission and optical clarity, it is useful in manufacturing of lenses, optical filters and light covers. This represents a low cost alternative to glass and is durable as well as impacting resistant in a variety of optical applications.

2. Signage & Displays

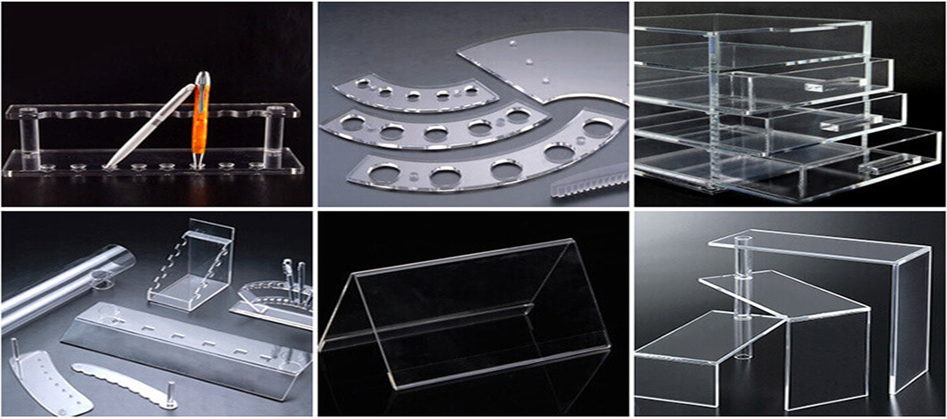

Acrylic molding is the type of plastic used in a lot of advertising and display manufacturing. Due to its capability to form out complex shapes and transfer light, they are commonly used in illuminated signs, display panels and bits of adornment signage.

3. Consumer Products

Acrylic injection molding is applied a lot for everyday things such as household accessories, decorative objects and toys. From a durability, aesthetic appeal and wear resistance point of view, it is a preferred material in the consumer goods industry.

4. Automotive Components

In the automotive industry, the internal fit and trim part for the interior trim, dashboard panels, light covers, and exterior accents is done by acrylic injection molding. It is a wonderful material to work with due to its ability to resist heat, UV exposure, and impact and is an ideal functional and design material.

5. Medical Equipment

Medical enclosures, diagnostic equipment, and protective covers can all be provided by acrylic because of its clarity, biocompatibility, and resistance to chemical attack. In medical applications, where strength and transparency coexist, it is used.

Acrylic injection molding still remains an important process because of the versatility, the cost and the precision that it offers.

Temperature Management in Acrylic Injection Molding

- Coating variation in acrylic injection molding is dependent on proper temperature management. Acrylic has a melting range of 130-140°C and can work in short stays of temperature from 65-93°C. As an insulator, it is known for easy heat-based molding and low thermal conductivity.

- Another important point is about drying of the material before processing. The water absorption rate for acrylic is 0.3-0.4% and excess moisture can create bubbles, gas lines and reduced clarity in a final product. Then, acrylic is dried to keep the humidity level way under 0.1 or better yet under 0.04%.

- Product quality and cycle time are highly dependent on the melt temperature. Acrylic, like other thermoplastics, melts in the 130–140°C range and the exact temperature should be closely controlled to stay on the proper side of molding efficiency versus matrix part durability.

Furthermore, the dimensional stability and surface quality of the finished product depends on the mold temperature as well. The following three best practices for optimum mold temperature are the case.

Use a Temperature Control System: The mold receives a precise control system that assures constant heat distribution to the whole mold.

Monitor Temperature Regularly: It helps with warping, shrinkage, or surface imperfections, by checking and adjusting the mold temperature.

Optimize Cooling Channels: With properly designed cooling channels, high heat capacities are available for removing heat, reducing cycle times, and also providing uniform cooling.

Additional Considerations in Acrylic Molding

In addition to temperature control, heat deflection temperature, ultrasonic welding, and mold cost should be taken into account to further enhance the product quality and production efficiency.

Heat Deflection Temperature (HDT)

The HDT of acrylic is in the range of 80 to 100°C, indicating the deform begins at this temperature point but under load. However, the laws of heat transfer limit the maximum allowable processing temperatures below HDT to obtain dimensional accuracy and optical clarity.

Ultrasonic Welding

Ultrasonic welding is a reliable process with multiple acrylic parts. To create heat, this process employs high-frequency sound waves to fuse components, with little or no visible marks on them, making it ideal to use on LFT parts.

Mold Cost

Acrylic injection molds are expensive due to complexity, material selection and design requirements. Harmonizing this general objective is reducing costs that manufacturers can achieve by designing or selecting part designs that are simplified, using mold components more than once, and utilizing appropriate mold materials.

Environmental & Health Considerations

Modern injection molding machines with 20 to 50 percent less electric use than older machines are energy efficient but electricity consumption is still a concern for the environment. Acrylic molding can produce dangerous fumes if not managed properly, and it does not finish in a cabinet, when not flushed out and the back cut thus the dust particles could potentially be pushed into your lungs. Ventilation systems, fume control measures and adequate safety were also supposed to be in place to ensure worker safety in manufacturing facilities.

Alternative Materials in Injection Molding

Acrylic is one of the materials that are commonly used for optical clarity and durability, but it is not the only material.

Polycarbonate (PC)

More impact-resistant than acrylic, making it ideal for safety equipment and automotive parts. It is however not transparent as acrylic.

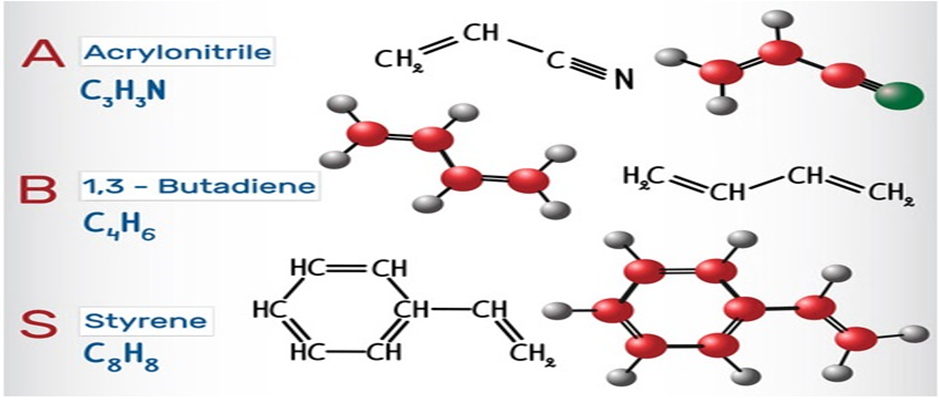

ABS (Acrylonitrile Butadiene Styrene)

A plastic with good strength and moldability but which has poor high optical clarity that is both cheap and easy to process. Common in automotive parts, toys, and appliances.

Polypropylene (PP)

Chemical resistant and flexible, it is a popular option for packaging and consumer goods applications. Secondly, however, it is not transparent like acrylic.

ASA (Acrylonitrile Styrene Acrylate)

UV resistance and weather ability provide it with outdoor application ability.

COC (Cyclic Olefin Copolymer)

Low water absorption; chemical resistant; known for medical and optical applications.

PCT (Polycyclohexylenedimethylene Terephthalate

It offers high heat resistance and optical clarity; which is commonly used in automotive lighting.

Each of these materials has unique strength, transparency and environmental factors of interest and the right selection depends on which is to be used for the intended application.

Acrylic Injection Molding Design Guidelines

Nonetheless, when designing with acrylic, it is important to observe standard design principles to avoid defects in your acrylic parts and to achieve maximum manufacturing efficiency. High quality durable components rely on proper wall thickness, radii, draft angles and tolerances. A number of key design considerations of acrylic molding is given below.

Wall Thickness

Acrylic part wall thickness should be between 0.025 inches (0.635 mm) and 0.150 inches (3.81 mm), according to recommendations. There is no tolerance for inconsistency in wall thickness since change (whether sudden or gradual) can produce defects such as warping, sink marks or internal stress.

Radii and Corners

A quick look at acrylic will show you that the acrylic is prone to stress concentrations at sharp corners. Corners with a minimum radius 25% of the wall thickness should be used to improve moldability and structural integrity. The best radius for increased strength is 60% of the wall thickness.

Draft Angles

The draft between 0.5° and 1° is necessary to create a smooth ejection out of the mold. If the part has polished or optically clear surfaces, then you may need a greater draft angle to maintain the quality.

Part Tolerances

Acrylic injection molding tolerances for part size and precision requirements are as follows:

- For parts up to 160 mm, Commercial Tolerances are 0.1 mm to 0.325 mm.

- Fine Tolerances: 0.045 mm to 0.145 mm for parts 100 mm or smaller.

By following these design principles, precision, durability, and optimal performance for its mold are assured in acrylic plastic molding.

Types of Acrylic Molds and Their Significance

Single-Cavity vs. Multi-Cavity Molds

Single-Cavity Molds: A low-volume production is suitable for good precision and customizability.

Multi-Cavity Molds: To meet the requirement of mass production with less time and less cost for each unit produced.

Hot Runner vs. Cold Runner Molds

Hot Runner Molds: Minimize waste and improve efficiency by keeping the acrylic molten inside the system.

Cold Runner Molds: More cost-effective but excessive material production, thereby requiring trimming and recycling.

Custom Acrylic Molds for Specialized Manufacturing

However, manufacturers can use custom molds to produce complex designs with tight tolerances, guaranteeing that acrylic components are manufactured to the certain specifications demanded in the aerospace and medical technology sectors.

Advantages and Challenges of Acrylic Plastic Molding

Advantages of Acrylic Molding

Exceptional Clarity: An outstanding substitute for glass is acrylic featuring up to 92 percent transparency.

Lightweight & Strong: Glass is twice heavier than acrylic but it is still very durable.

Weather & UV Resistance: Although some plastics grow yellow or degrade, acrylic does not.

Customizable Properties: Besides, acrylic can be dyed, coated,d, or modified for various applications.

Challenges in Molding Acrylic

Brittle Compared to Polycarbonate: While PC is less impact-resistant as acrylic, it will withstand much more pressure before cracking.

Shrinkage Control: Warpages and defects may occur if temperature management is not very precise.

Longer Cooling Time: Acrylic’s relatively low thermal conductivity leads to longer cycle times and hence reduces efficiency and production output.

Acrylic Molding vs. Other Plastic Molding Processes

| Property | Acrylic (PMMA) | Polycarbonate (PC) | ABS Plastic |

| Transparency | 92% clarity (glass-like) | 85% clarity | Poor |

| Impact Resistance | Moderate | High | High |

| Heat Resistance | Moderate (80-100°C) | Excellent (120-140°C) | Good |

| Scratch Resistance | High | Moderate | Low |

| Cost | Affordable | Expensive | Cheap |

Polycarbonate is best with regard to impact resistance while acrylic is chosen for their optical properties. In low cost applications if this flexibility and toughness is the priority then you can use ABS.

Future Trends in Molding Acrylic for Industrial Applications

- Acrylic molding is becoming the next big thing and driving the future in the following aspects:

- 3D printed acrylic molds can, on one hand, improve the prototyping speed and save the money for fabricating the mold.

- Manufacturers are tapping into recyclable & Eco-Friendly Acrylic to reduce waste.

- Integration of AI and IoT is making manufacturing process control and quality assurance smarter, thus optimizing the Smart Injection Molding Machines.

- Nano-Coated Acrylic – Enhancing scratch resistance and UV protection for long-term durability.

Sincere Tech – Trusted Acrylic Injection Molding Services

Sincere Tech is proficient in Plastic injection molding and acrylic injection molding with high quality that’s suitable for automotive, medical and electronics industries. With technology advanced and skilled engineers around, they create very clarity and durable precision acrylic parts.

With its custom mold design and manufacturing expertise, it provides cost-effective solutions both for prototyping and mass production. Sincere Tech uses high-grade material to make our high UV-resistant, high impact-resistant, high optical clear acrylic components.

Sincere Tech is the cheap acrylic molding provider for its reputation for quality, efficiency and innovation. For the tailored plastic molding services at the highest precision today, contact them!

Conclusion

Acrylic injection molding allows strong, lightweight and optically clear components to be produced. With brittleness and shrinkage control yet to be solved, it has nonetheless proved itself to be an inexpensive replacement for glass when precision and durability are required. In line with the change in manufacturing, smart molding technologies, automation, and sustainable acrylic solutions will also lead the way. Nevertheless, this material will definitely continue to find its place in the modern applications of industry since the growing demand for customized, high performance acrylic products guarantees that this material will continue to serve as a solution both for mass production and specialized manufacturing purposes.

FAQs

1. Why does one make use of acrylic in injection molding?

Acrylic provides high clarity (92%), UV resistance, longevity, and affordable price, while being a suitable choice for transparent and weather-resistant items.

2. Where can acrylic molding be utilized?

Acrylic is common in automotive, medical, consumer goods and signage because of its strength, clarity and versatility.

3. Why is molding acrylic challenging?

It can be brittle, can warp, and requires very tight temperature control in order for defects to not form.

What are the differences in acrylic as compared to polycarbonate and ABS?

Acrylic is less clear, but more scratch-resistant compared to PC, while cheaper ABS does not transparent.