The current fast world revolves around innovation. The companies and inventors must be in a position to transform ideas into concrete products within a short time. This is where rapid prototyping service comes in; through rapid prototyping, the designer and the engineers can create a real-life model of their idea before they fully commit to production. It is time-saving, cost-reducing, and improves the quality of products.

Among the elements of this process, the use of rapid prototype services is one of them. These services facilitate the conversion of web designs into actual products. These services are required for an entrepreneur or a company. Quick prototyping allows the development of prototypes that can also be used to test the design and identify defects and correct them within a minimal time.

What is Rapid Prototyping?

Rapid prototyping is a technology that allows designers to develop a physical model of a digital design within a short period. Ideas can be translated into actual items through a rapid prototyping service in order to be tested and refined. With the services of rapid prototyping, companies can see the picture of how a product will look and function even before full production. Quality and precision are ensured through the application of professional rapid prototyping services and the capacity to produce strong and quality parts through using rapid prototyping machining services. The rapid prototyping service makes innovation fast, safe, and more cost-effective.

Rapid Prototyping Services Definitions

Rapid prototyping is the technology that is applied to create 3D models with the help of Computer-Aided Design (CAD) files very quickly. In the design process, a rapid prototyping service is required. It helps in improving the innovation, product designs, and the reduction of lead times.

All the rapid prototype services may be of different types. These include tooling and fixturing, low-volume production parts, among others. Three-D printing of Lost Wax Prototyping (LW) is a technology that can be used in prototyping.

An example would be a prototype of a new defense equipment by an engineering company, which can be a prototype that is manufactured through a so-called rapid prototyping service. They give the provider a specifications file that is comprehensive in the form of a CAD file. FDM can be used to develop a prototype in just a couple of hours or days. This is much faster than the traditional production that could take weeks.

Professional rapid prototyping services can be used by companies to gain access to high-quality prototypes that can be utilized in testing and visualization. Rapid prototyping machining services can also be used in cases of precision and strength. They can be found applicable in cases where the inventors, artists, engineers, and contractors in the defense industry need models that function or rapid visual aids.

Rapid prototyping Process

Rapid prototyping will help to convert ideas into actual and experiment able models in a very short duration. To be precise and effective, a rapid prototyping service has a set of steps that are adhered to.

Designing the Model

The first one is the creation of a digital design through the assistance of CAD software. This is the file, which is a prototype blueprint for the one prototype with the rapid prototype services. The model that is developed will be able to provide precise results because of the appropriate design.

Selecting Materials

It is significant to choose the right material. The use of so-called professional rapid prototyping services is based on the selection of plastics, metals, composites, or ceramics, depending on the needs of the project.

Building the Prototype

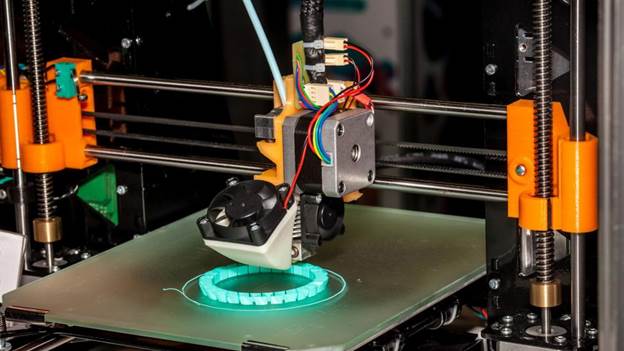

With the aid of relevant methods, the prototype is developed. The rest of these use 3D printing, and some can be manufactured with the assistance of the rapid prototyping machining services, where the parts are accurate or solid.

Testing and Evaluation

The prototype is tested on functionality, fit, and strength after construction. One of the services is rapid prototyping, which would help make quick adjustments towards better design.

Finalization and Refinement

The prototype is reduced to specifications once it has been tested. The final model production or presentation needs to be made ready with professional rapid prototyping services.

The so-called rapid prototyping services allow saving time, reducing costs, and putting ideas into practice with minimal effort after such a process.

Application Design innovation reflects the continuous progress of any product or service

In the design innovation, rapid prototyping plays a significant role. The latter is the so-called rapid prototyping service that allows the designers to create the models in a very short time and test the novel ideas within a short time frame. This helps in reducing errors and improving the quality of products.

Testing New Concepts

The so-called rapid prototype services also enable designers to transform ideas into real-life models. This allows the teams to see, feel, and experiment with ideas till full production.

Improving Product Design

Professional rapid prototyping services are applied to perfect the design on a testing and feedback ground. Assuming small modifications, it is possible to implement them within a rather short time to save time and costs.

Accelerating Development

Rapid prototyping machining services are also faster than conventional ones in making complex parts and even functional prototypes. This makes the innovation process easier.

Creative Exploration: Support

It is a service that will allow inventors, engineers, and artists to test multiple ideas by developing a rapid prototyping service. This flexibility encourages the capacity to produce new solutions and high-quality end products.

The companies can be more innovative, less risky, and produce the products to meet the requirements of the market through rapid prototype services.

A technical table of the different rapid prototyping methods

| Prototyping Method | Material Type | Layer Resolution (mm) | Build Speed (cm³/hr) | Typical Cost per Part ($) | Strength (% of Final Product) |

| Fused Deposition Modeling (FDM) | ABS, PLA | 0.1 – 0.3 | 15 – 25 | 50 – 200 | 60 – 70 |

| Stereolithography (SLA) | Photopolymer Resin | 0.025 – 0.1 | 8 – 15 | 80 – 300 | 50 – 65 |

| Selective Laser Sintering (SLS) | Nylon, PA12 | 0.05 – 0.15 | 10 – 20 | 100 – 400 | 80 – 90 |

| Multi-Jet Modeling (MJM) | Resin | 0.016 – 0.03 | 5 – 10 | 150 – 500 | 55 – 70 |

| Laminated Object Manufacturing (LOM) | Paper, Plastic, Metal | 0.1 – 0.3 | 20 – 40 | 60 – 250 | 40 – 60 |

| CNC Machining | Aluminum, Stainless Steel | 0.01 – 0.05 | 5 – 15 | 200 – 1000 | 90 – 100 |

Notes:

Layer resolution: A minimum thickness of a feature that can be reliably printed/machined.

Build speed: the volume of material (approximately) that is printed per hour

Strength: percentage that is near the end product part.

The Ideal Customers of Rapid Prototyping Services

Rapid prototyping can be of assistance to many professionals. Rapid prototyping service can also help everybody in situations where there is a need to realize the ideas in actual, testable models in a short duration.

Inventors and Businessmen

The rapid prototype services are beneficial to start-ups and inventors because they do not need to incur a lot of cost in production to create such prototypes. This helps in experimenting and attracting investors.

Engineers and Designers

Professional rapid prototyping services: They are the services that help the engineers and the product designers to develop correct and working prototypes. This helps in improving designs and reducing mistakes in production.

Imaginative Professionals and Artists

It is possible with the help of a so-called rapid prototyping service, which enables artists or other individuals in the creative business to make their ideas come to life. Prototypes provide a visual representation that can be applied in planning, presentations, or displays.

Contractors in Industry and Defense

Machining services o5f the rapid prototyping services are highly demanded by industrial or military companies to provide high-quality components that are durable, more accurate, and functional. This increases the rate of development and testing.

Educational Institutions

The services of rapid prototyping are applied in schools and universities to teach the students how design, engineering, and manufacturing processes are brought about. It makes it possible to provide practical education with real models.

These users will have the ability to save time, save money, and improve the overall quality of their projects by incorporating a rapid prototyping service.

Professional-level Rapid Prototyping Services

Quality is an aspect of selecting a service provider. A professional rapid prototyping services ensure that your model is faultless and effective. These services have high technology like 3D printing, CNC machining, and laser cutting. Materials, tolerances, and design complexities are better known to professionals. You will even be certain that your product will be as high-quality as possible with the assistance of the so-called free rapid prototyping services offered by professionals.

The input of Rapid Prototyping Machining Services

Other designs are not something that can be simply 3D printed. With this comes the rapid prototyping machining services, which can be done on metals, plastics, and composites. They are capable of providing precision, besides the excellence that traditional prototyping might not provide. Under these services, it can be guaranteed that your prototype will be the real product. The integration of rapid prototyping machining services with other prototyping processes that produce the most optimal outcomes is not uncommon with most companies.

What are the Significant Essentials in the fundamental technical procedure of Rapid Prototyping?

Creating a Digital Design

The first step in the rapid prototyping process would be an elaborate computer-aided design in a CAD program. It is the prototype blueprint of this design. A so-called rapid prototyping service is then used to access the file, which enables moving through the entire process in the right direction.

Choosing the Right Material

The selection of the appropriate material is essential. Recommendations can be made on material, based on strength, flexibility, and durability, by professional rapid prototyping services. The right choice would ensure that the prototype behavior mimicked the final product.

Building the Prototype

The prototype is then developed through rapid prototype services. This may be 3D printing, casting, or machining, depending on the method to be applied. The most important ones are high precision or metal parts, and rapid prototyping machining services.

Testing and Evaluation

Once the prototype is created, there is a test of the prototype in terms of functionality and accuracy of design. The adjustments and improvements can be made within a short time period through a rapid prototyping service and move to full-scale production.

Finalization and Refinement

The prototype is further enhanced based on the results of the testing. The professional rapid prototyping services ensure that changes that have been introduced are effectively introduced, and a stable model designed to be used in production is developed.

Types of Rapid Prototyping Services

There are many different types of rapid prototyping service approaches. The two methods can be used based on the need, materials, and level of accuracy. The application of the suitable type accelerates and makes the development more successful.

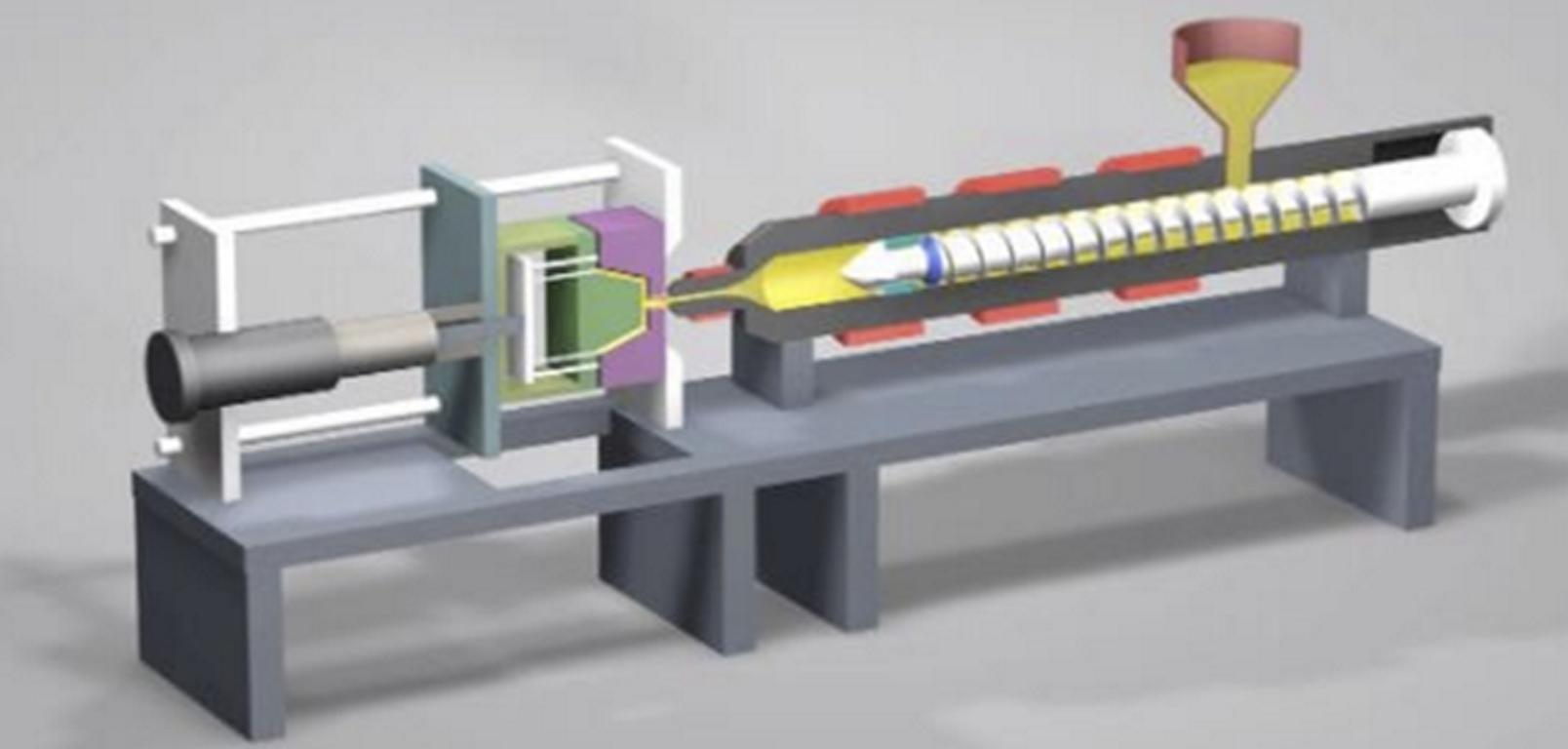

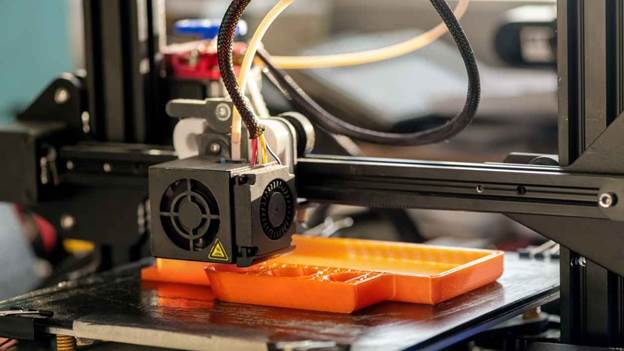

Fused Deposition Modeling (FDM)

FDM is one of the most popular rapid prototype services. It is developed on the additive strategy of producing parts in layers of thermoplastic type. It is also fast, cheap, and it applies to both small- and medium-detailed designs.

Stereolithography (SLA)

SLA works with the use of a laser to solidify liquid resin. The use of SLA in making fine prototyping is common in the SAW Professional rapid prototyping services. It generates curved surfaces and precise models that can be put into practice and presentation.

Selective Laser Welding (SLS)

In SLS, it is by means of a laser that powdered materials are fused. The method allows the machining services of rapid prototyping to produce durable and functional parts. SLS can be used in the testing of both mechanical properties and small batches of functionality.

Multi-Jet Modeling (MJM)

A prototype is created by coating materials created by MJM. It can capture the correct geometry and can produce rich geometries. MJM is mainly applied to visual models and complex designs through a rapid prototyping service.

lost wax Laminated Object Manufacturing (LOM)

LOM is a process of prototype building through a series of layering of materials. LOM Rapid prototype services would suit large parts and complex structural designs. It is cost-effective with regard to structuring early validation.

Various types of rapid prototyping services are advantageous. With the help of professionals, it is possible to choose the most appropriate way to save time and create high-quality prototypes.

The benefits of Rapid Prototypes

Time is an extremely crucial issue in the development of products. Rapid prototype services are models that are developed quickly. You are now able to test, change, and improve designs within days as opposed to months earlier. This limits the overall product development. Moreover, a prototype will help to sell an idea to investors, clients, or team members. They can watch, touch, and even understand your idea fully.

The other strength is the economy. It might be an expensive undertaking to have a complete production model. The prototyping will ensure that the errors are detected in good time. The companies save on the costs incurred in undertaking costly revisions at a later stage. One of the smart ways of innovation is by using rapid prototype services, which is a cost-effective tool.

The Significance of Professional Services

Not all prototyping is equal. They offer rapid prototyping services using professional rapid prototyping services which are accurate and of high quality. The professionals ensure that there is the right size, material selection, and testing. The amount of experience is especially important in the case of complex projects or products with highly restrictive specifications. With them, the prototype is transitioned into production is done smoothly.

The Operation of Rapid Prototyping Machining Services

Scientific technique: how to design a new mechanical component. One can have a 3D model that is computer-generated. But to be exercising life, you need a part. This is where the rapid prototyping machining services come in. Machining allows metal and high-strength plastic parts to be produced in a short duration. You can do experimentation with movement, strength, and assembly before mass production. The best way is to integrate the services of rapid prototyping machining with other methods.

What are the Major Capabilities that a person is supposed to consider when selecting a Rapid Prototyping Service Provider?

One of the main factors in successful prototyping is the relevant provider. Not all the suppliers of the rapid prototyping service are equally good, fast, or skilled. The most significant capabilities to consider are the following:

Expertise and Experience

He/she is expected to offer years of experience in the sphere of professional rapid prototyping services. In designing, experts are aware of materials, tolerances, and complexities so that there are working and correct prototypes.

Technology and Equipment

The new technology used in the introduction of rapid prototype services nowadays is 3D printers, CNC machines, and laser cutters. Rapid prototyping machining services are also significant, such that there has been some form of precision, and also to manage the complex or metal parts.

Material Selection

It is important to work with a great number of materials. The right rapid prototyping service can assist you in making a choice of plastics, metals, or composites based on your project requirements.

Speed and Turnaround Time

The speed of the provider is most important as rapid prototyping is a time-saving aspect. Quick prototype services will be efficient enough, and will reduce the product development cycles, and will enable your ideas to become marketable faster.

Quality and Accuracy

Accuracy is necessary in prototypes that are going to be tested or used in planning production. Professional rapid prototyping services ensure that their models are of high quality and that they are ordered every time.

Support and Consultation

A great provider gives guidance during it. The usage of the rapid prototyping machining services with the help of professionals ensures the optimization of the designs and exclusion of potential issues.

A Materials Rapid Prototyping Table

| Material | Type | Tensile Strength (MPa) | Flexural Strength (MPa) | Density (g/cm³) | Typical Use |

| ABS | Thermoplastic | 40 – 50 | 65 – 75 | 1.04 | FDM prototypes, functional parts |

| PLA | Thermoplastic | 50 – 70 | 70 – 90 | 1.24 | FDM prototypes, visual models |

| Photopolymer Resin | Thermoset | 45 – 65 | 80 – 100 | 1.1 – 1.2 | SLA/MJM, detailed models |

| Nylon (PA12) | Thermoplastic | 48 – 70 | 60 – 90 | 1.01 | SLS functional parts, durable prototypes |

| Aluminum 6061 | Metal | 290 | 310 | 2.70 | CNC machining, functional prototypes |

| Stainless Steel 316 | Metal | 520 | 550 | 8.0 | CNC machining, high-strength parts |

| Composite (Carbon Fiber + Nylon) | Composite | 100 – 120 | 120 – 140 | 1.3 – 1.5 | High-strength prototypes, functional testing |

| Ceramic | Ceramic | 150 – 300 | 200 – 400 | 2.0 – 3.5 | Heat-resistant prototypes, electronics |

Notes:

Tensile Strength: the maximum amount of stress that a material can withstand.

Flexural Strength: the maximum stress before a bend or bend.

Density: Mass/ volume of unit volume, which is important in the computation of weight.

Future of Rapid Prototyping

Technology is evolving fast. Also, the present-day rapid prototyping service is more material and faster to manufacture than it has ever before. Innovations in 3D printing as well as CNC machining are resulting in prototypes that are increasingly similar to final products. Businesses are also able to explore, re-try, and innovate more than ever seen before.

You will maintain competitiveness in your product when outsourcing the so-called professional rapid prototyping services. The faster one makes a prototype, the faster he may test and get better. Time-to-market is also shorter, and customer satisfaction is lower.

Materials of Rapid Prototyping

The rapid prototyping service is highly sensitive to the selection of material. It affects the sturdiness, strength, and accuracy of the prototype. The different so-called rapid prototype services are dependent on the type of project and the type of test, based on their own materials.

Plastics

Plastics are the most utilized. ABS, PLA, or resin is commonly found as part of FDM or SLA. The professional rapid prototyping services decide the choice of the plastics used in lightweight, cost-effective, and intricate models.

Metals

The quick prototyping machining service takes place with such metals as aluminum, stainless steel, or titanium, in the case of efficient and strong prototypes. These are the finest materials that can be used in mechanical tests and powerful components.

Composites

Composites refer to a combination of different materials to offer strength and flexibility. Prototypes have been made using composites that are resistant to stress and wear, and also accurate through a rapid prototyping service.

Ceramics

Other prototypes needed heat-defiant or special finishes. Rapid prototype services are capable of producing models of ceramic materials in models based on electronics, aerospace, or special industries.

The choice of the correct material can ensure that a prototype delivered with the help of a rapid prototyping service is precise, working, and can be tested or demonstrated.

Choosing the right Service Provider

One should possess the correct rapid prototyping service. Consider experience, technology, material, and turnaround time. The local supplier will provide design advice, materials, and process advice. It requires collaboration and communication to use fast prototype services adequately. Professionals assist in refining your design and avoiding the common errors.

Rapid Prototyping Services Applications

Services of this kind do not fall under one industry. They are used in consumer electronics, automotive, aerospace, medical equipment, etc. Rapid prototype services also allow engineers to test new designs in a safe location. They are mainly used in high-precision industries, especially in rapid prototyping machining. Professionals provide an idea about materials and manufacturing processes and ensure that the prototypes work.

Sincere Tech: Your Trustworthy Partner of Rapid Prototyping

Sincere Tech is a progressive developer of the so-called rapid prototyping service solutions with the principles of turning the idea into reality. At Sincere Tech, we offer low-cost and rapid prototyping services, and these services fit the requirements of inventors, engineers, and companies. Our rapid prototyping services are also professional, precise, efficient, and durable in all their projects. Being equipped with modern technologies and proficient in the domain of rapid prototyping machining services, we help our clients to reduce expenses, save time, and speed up the process of innovations. Working with Sincere Tech will mean dealing with a team that is well organized, whose mandate is to develop proper, functional, and inventive prototypes for every industry.

Conclusion

A rapid prototyping service is used to transform an idea into reality. The companies can develop, test, and refine their products more effectively and within a shorter time through the rapid prototype services. With the assistance of the services of rapid prototyping machining, the precision and strength, as well as the quality and accuracy, are controlled.

It is no longer an option to invest in such services in a competitive market. It is required due to innovation, cost-saving, and reduction in the time to market. Be swift to react, adopt a quick-prototyping service, engage in cooperation with specialists, and get your concepts moving.