Acrylic injection molding can be defined as a new technology of manufacturing plastic products with high quality. The technique has a wide application in the automotive industry, healthcare sector, consumer goods, and electronics. It is particularly renowned for making transparent, tough, and attractive products.

China is a major part of the acrylic molding business. China has large quantities of factories that manufacture high-quality acrylic molds and parts. They offer cost-effective, dependable, and scalable production to the international markets.

This paper covers the process of injection molding, types of molds, applications, and best practices in acrylic injection molding.

What is Acrylic Injection Molding?

Acrylic injection molding is an aircraft production technique in which acrylic plastic is warmed up until it melts and then injected into a mold. The plastic is cured and solidifies into a given shape. The process is very useful in the large-scale production of complex and consistent parts.

The acrylic pellets are small and used as the starting food materials. These are poured into a heated barrel until it melts. Then the molten acrylic is injected into high pressure mold with acrylic molds. The molds are cooled and opened, and the finished product is ejected.

The process is fast, accurate, and economical, unlike other methods of molding. It suits industries where the quantity of production is needed without necessarily touching on the quality.

Benefits of Acrylic Molding

There are numerous benefits of acrylic molding.

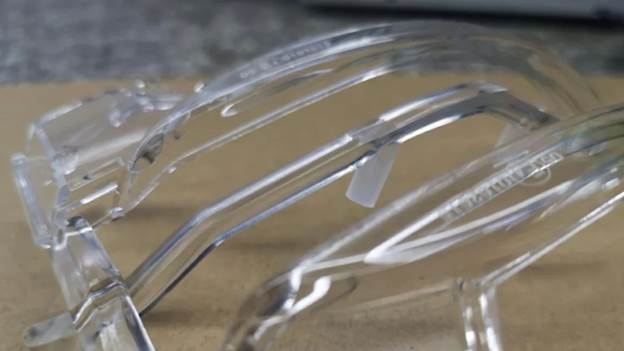

- Large Transparency: Acrylic products are very transparent. They are frequently applied in situations when it is necessary to be visual.

- Durability: Acrylic is durable and scratch-resistant.

- Complex Shapes: It is able to do complex designs, which are hard to do with other plastics.

- Cost-Effective: After creating molds, thousands of pieces can be created in a short time, which makes the process less expensive.

- Consistency: Each batch is the same as the preceding one, and quality is ensured in high quantities.

The acrylic molding is quick and accurate, and hence a good option where quality and speed are expected in industries.

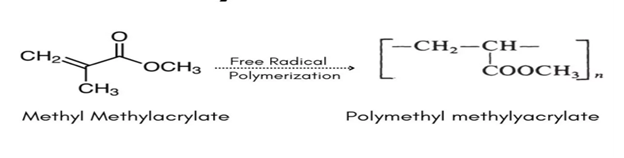

Acrylic Injection Molding was discovered

In the mid-20th century, the manufacturers of the process started to develop the process of acrylic injection molding because the manufacturers wanted to find a quicker and more accurate method of shaping PMMA. Previously, casting was used as the primary process of acrylic molding, which was a slow and work-consuming process.

Machines that could melt acrylic pellets at temperatures of 230-280 °C and inject them into small acrylic molds were invented by engineers in Germany and the United States in the 1940s and 1950s. This invention made it possible to manufacture intricate and high-quality parts that had uniform dimensions.

Injection techniques of acrylic to produce what is today known as the molding of acrylic transformed industries such as automotive, medical devices, and consumer products. Acrylic plastic molding not only reduced the time but also increased efficiency, but it also made parts that had tight tolerances (+-0.1 mm) and those that were optically clear (>90% light transmission).

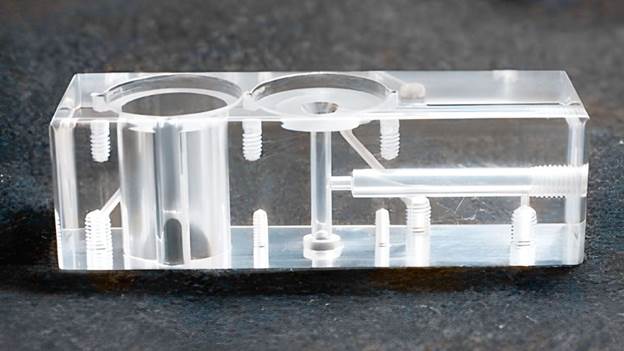

Types of Acrylic Molds

There are several types of acrylic molds; each model is produced according to the required production nature and complexity of the product. The selection of a suitable type guarantees results of high quality and efficiency in acrylic molding.

Single-Cavity Molds

Single-cavity molds are made to make a single part after each injection cycle. They can be used when the production run is small or in prototypical projects. With single-cavity molds, the process of injection molding acrylic material is done using the term under consideration in order not to have to deal with the problem of incorrect shaping and vague surfaces.

Multi-Cavity Molds

Multi-cavity molds are able to manufacture many copies within one cycle. This gives them ideal suitability for massive production. Multi-cavity molds are frequently molded with acrylic to accomplish consistency and minimize the time of production.

Family Molds

In a single cycle, family molds generate some of the various parts. This is a type that is practical in formulating components that constitute a product assembly. Family molds can use acrylic plastic molding that enables multiple pieces to be manufactured at the same time, which saves both time and cost.

Hot Runner Molds

The Hot runner molds allow the plastic to be kept in channels to minimize wastage and enhance efficiency. Hot runner systems use acrylic molds that fit high-precision products with smooth surfaces and fewer defects.

Cold Runner Molds

Cold runner molds employ channels that cool together with the part being molded. They are less costly and easier to produce. A lot of small to medium-sized manufacturers would rather use acrylic molding by using cold runner molds to do their production cheaply.

The choice of the appropriate type of the so-called acrylic molds is determined by the volume of production, the design of the product, and the budget. Correct selection of molds leads to better performance of acrylic injection molding and finished products of high quality.

The techniques of Acrylic Plastic Molding

Acrylic plastic molding is the process of using several methods to convert acrylic substances into useful and attractive items. Both approaches have strengths, which are determined by design, volume of production, and the needs of the product.

Injection Molding

The most popular one, which is called acrylic injection molding, consists of heating acrylic subunits, called acrylic pellets, until molten, and its injection into acrylic molds. Upon cooling, the plastic will solidify in the intended shape. This is the best method to make a high-precision product in massive quantities.

Compression Molding

Acrylic sheets are put in a hot mold and pressed to form in compression molding. This technique can be applied to thicker sections and plain designs. Compression molding of acrylic is used to make it uniform in thickness and strength.

Extrusion

Long continuous profiles are made by extrusion, where molten acrylic is forced into a shaped die. By extrusion, acrylic molding is used on such items as tubes, rods, and sheets. It is even in cross-sections and surfaces.

Thermoforming

The thermoforming technique heats acrylic sheets until pliable and shapes them over a mold with the vacuum or pressure. The approach works well with huge or non-huge products. Thermoforming is a technique of manufacturer of low to medium volumes of acrylic plastic molds at a reasonably low cost.

Rotational Molding

Rotational molding is also used with acrylic, but the mold is rotated during heating to evenly coat the inside of the mold. Shapes with hollows can be made effectively using this technique. In rotational molds, there is the flexibility of molding acrylic to fit some designs.

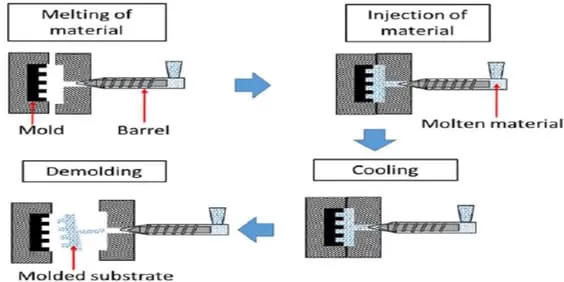

Process of Molding Acrylic

Molding acrylic is an important and technical process through which the raw acrylic material is changed into finished parts of high quality. The procedure comes with several processes, and each process entails precise control of temperature, pressure, and time to provide the optimal outcome in the process of acrylic molding.

Material Preparation

The reaction begins with acrylic high-quality pellets, which can be of different sizes (usually 2-5 mm in diameter). The moisture content of the pellets should be less than 0.2, and any further moisture may lead to bubbles in the process of molding. The pellets are normally dried in a hopper dryer at 80-90 deg C in not less than 2-4hours before usage.

Melting and Injection

The dried pellets are introduced into the barrel of the injection molding machine. The temperature of the barrel is maintained at 230-280 °C, with acrylic grade depending on the grade used. The pellets are melted by the screw mechanism to form a homogeneous acrylic mixture in molten form.

The acrylic is then injected at high pressure – normally 70-120 MPa – into acrylic molds once molten. The time of injection depends on the size of the part, with the small to medium parts taking about 5 to 20 seconds.

Cooling

A pressurized mold is placed after injection as the acrylic cools and solidification takes place. The time of cooling varies with the thickness of parts:

- 1-2 mm thickness: 15-20 seconds

- 3-5 mm thickness: 25-40 seconds

- Above 5 mm thickness: 45-60 seconds

The cooling is necessary to eliminate warping, shrinkage, or surface defects. Established molds may also make use of water pipes or oil cooling to maintain the temperatures in the required specifications.

Mold Opening and Ejection

The mold is opened once it has cooled, and the part is ejected with mechanical or hydraulic ejector pins. It should be noted that the force of ejection should be limited to ensure that it does not damage the surface or deform it.

Post-Processing

The part may also go through finishing procedures like clipping off or polishing the part after ejection, or annealing. Aging at temperatures of 80-100 deg C 1-2 hours of aging assists in removing internal stresses and enhancing clarity and strength.

Quality Inspection

Individual components are checked against defects such as air bubbles, warping, and dimensionality. Calipers are utilized, or a laser scan is undertaken, and tolerance is allowed to be within + 0.1 mm when dealing with high precision components. The application of acrylic plastic molding, which is of good quality, has ensured that all its products are industry standard.

Summary of Process Parameters:

| Step | Parameter | Value |

| Drying | Temperature | 80–90°C |

| Drying | Duration | 2–4 hours |

| Barrel Temperature | Melt Acrylic | 230–280°C |

| Injection Pressure | 70–120 MPa | |

| Cooling Time | 1–2 mm thick | 15–20 sec |

| Cooling Time | 3–5 mm thick | 25–40 sec |

| Cooling Time | >5 mm thick | 45–60 sec |

| Annealing | Temperature | 80–100°C |

| Annealing | Duration | 1–2 hours |

| Dimensional Tolerance | ±0.1 mm |

The acrylic molding with the following technological characteristics guarantees the quality, accuracy, and efficiency of each product. The process of acrylic injection molding can be used to manufacture clear, durable, and dimensionally accurate components by using optimized conditions, which ensure consistent production of the components.

Uses of Acrylic Injection Molding

The acrylic injection molding is heavily applied in sectors where accuracy, clarity, and longevity are required.

Automotive Industry

Tail lights, dashboards, and trims are made as a result of acrylic molds. Parts are typically 1.5-5 mm thick, and with a temperature range of -40 °C to 80 °C. Clarity and longevity are guaranteed by Molding acrylic.

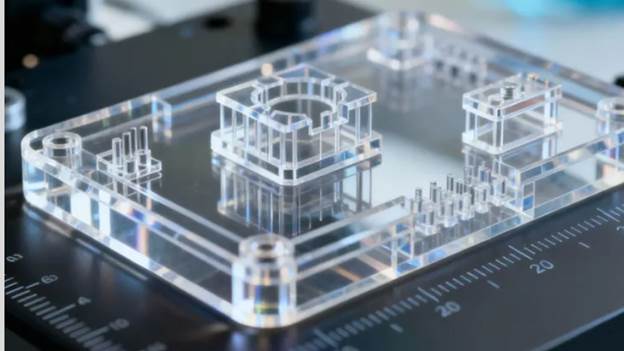

Health care and medical equipment.

Lab equipment, instrument covers, and protective shields are manufactured by the process of Acrylic plastic molding. There is a requirement for parts with tolerances of +-0.1 mm and the ability to be sterilized. Acrylic injection molding ensures smooth and correct surfaces.

Consumer Electronics

Smartphone covers, LED housings, and protective screens are molded with acrylic. Part must have a gloss on the surface exceeding 90% and accurate dimensions.

Amphetamine, Methamphetamine, and amphetamines in household and decoral products.

Such products as cosmetic containers, display cases, and panels are manufactured with the help of using the so-called acrylic plastic molding. The average thickness varies between 2 and 8 mm, which provides even finishes with smooth, clear, and colorful finishes.

Electrical Components, Lighting, and Optics.

The acrylic injection molding is used in the clarity of LED lenses, light diffusers, and signage. The parts attain transmission of light to the tune of over 90% at specific angles and thickness.

Industrial Equipment

There is the use of machine guards, instrument panels, and transparent containers, which are based on acrylic molding. Components require an impact strength of 15-20 kJ/m2 and be clear.

Typical Applications

This Framework is applied in situations when the government controls all the main features of healthcare services, such as quality, cost, and accessibility, and the amount of provided services.

Industry

- Product Examples

- Key Specifications

- Automotive

- Tail lights, dashboards

- thickness 1.5-5 mm, Temp 40 °C to 80 °C

Healthcare

- Test tube racks, shields

- Tolerance -0.1 mm, sterilization-resistant.

Electronics

- Covers, housings

- Surface gloss 90, dimensional stability.

Consumer Goods

- Containers containing cosmetics, exhibition boxes.

- Thickness 2-8 mm, smooth finish

- Lighting

- LED lenses, diffusers

- Transmission of light greater than 90, accurate geometry.

- Industrial

- Guards, containers

- Impact strength 15-20 kJ/m 2, clear.

Quality Control of Acrylic Molding

In acrylic molding, quality is essential in order to have parts that are up to standard. Some minor flaws can have an impact on performance and appearance.

Inspection of Parts

All the components are inspected against air bubbles, bending, and scratches on the surface. Calipers or laser scanners are used to measure so that tolerance is not exceeded by +-0.1 mm. The process of acrylic injection molding depends on regular checks as a way to ensure high quality of the output.

Mold Maintenance

Defects are prevented, and the life of the mold is lengthened by ensuring that it is regularly cleaned and inspected. The old molds may lead to inaccuracy in the dimensions or uneven surfaces.

Process Monitoring

Temperature, pressure, and cooling times are continuously checked during the process of molding acrylic. Barrel temperatures average 230-280°C and injection pressure ranges from 70 to 120 Mpa, to avoid mistakes.

Final Testing

Complete components are tested through functional and visual tests. As an illustration, optical components have to be inspected regarding the transfer of light (greater than 90 per cent) and structural parts regarding impact strength (15-20 kJ/m2).

This can be achieved by keeping a tight rein on the quality of the final product to generate dependable, accurate, and aesthetically flawless individual parts of acrylic plastic molding.

Selecting the appropriate Acrylic Injection Molding Alliance

When it comes to high-quality production, the correct choice of the manufacturer of the acrylic injection molding is crucial.

Experience and Expertise

Find partners who have experience in acrylic molding and acrylic molding. Experienced engineers would be able to maximize the mold design, injection, and finishing to specifications.

Equipment and Technology

Innovative machines that regulate temperature (230-280 °C), injection pressure (70-120 Mpa) are very specific in enhancing product consistency. The errors and waste are minimized with the help of high-quality acrylic molds and automated systems.

Quality Assurance

When it comes to a trusted supplier, they include rigorous checks of their parts, such as dimension checks (within -0.1 mm tolerance) and surface checks. With correct QA, it is ensured that the components of the acrylic plastic will be clear, durable, and defect-free.

Communication and Support

Good manufacturers interact during the designing and manufacturing process. They assist in the optimization of molds, propose materials, and material cycle time optimization.

Suggestions on Successful Acrylic Molding

It is advisable to follow best practices in acrylic molding to have high-quality, accurate, and durable parts.

Use High-Quality Material

Begin with acrylic 2-5 mm size pellets of less than 0.2 moisture content. Drying at 80-90°C 2-4 hours help in eliminating the bubbles and surface defects when molding acrylic.

Optimize Mold Design

Create an appropriate vented design and design acrylic molds with appropriate cooling channels and injection points. It minimizes warping, contraction, and cycle time in the process of injection molding of acrylic.

Control Process Parameters

Keep barrel temperature at 230-280 °C and injection pressure at 70-120 Mpa. Cooling time should be equivalent to part thickness:

- 1-2 mm – 15-20 sec

- 3-5 mm – 25-40 sec

- 5 mm – 45-60 sec

Inspect Regularly

Check parts’ dimensions (maximum error in dimensions 0.1 mm), light spots, and optical clearness (transmission greater than 90%). The advantage of acrylic plastic molding lies in the ability to perform consistent inspection.

Maintain Molds

Wash and clean molds so as to avoid wear and ensure smooth and consistent production. Molded acrylic finds increased efficiencies and quality of parts.

All these tips will give the process of acrylic injection molding a sure, no less attractive, and perfectly correct components every time.

Widespread Defects and Prevention

Defects can be experienced even in the case of accurate acrylic injection molding. Knowledge of causes and solutions guarantees the quality of acrylic molding.

Air Bubbles

Any air present in acrylic molds may produce bubbles on the surface.

Recommendation: Drying of acrylic NP with less than 0.2 percent moisture, correct ventilation of molds, and injection pressure of 70-120 Mackey’s.

Warping

Warping occurs, whereby the parts do not cool equally, hence they are distorted.

Resolution: homogeneous cooling channels, temperature of part, and part cooling time depending on part thickness (e.g., 1-2 mm – 15-20 sec, 3-5 mm – 25-40 sec).

Sink Marks

The sink marks are formed when the thick parts contract during cooling.

Solution: maximize the wall thickness, packing pressure, and adequate cooling rates in molding acrylic.

Short Shots

Short shots occur when the molten acrylic fails to fill the mold.

Resolution: Turn on more pressure in the injection press, clear blockages in acrylic molds, and verify correct barrel temperature (230-280 °C).

Surface Defects

Rough or scratches decrease transparency in acrylic plastic molding.

Remedy: Polish molds, do not use too much ejection power, and keep processing areas clean.

Outlook of Acrylic Injection Molding

Technology, efficiency, and sustainability are the future of acrylic injection molding.

Advanced Automation

The acrylic molding is becoming more and more automated and robotic. Temperatures (230-280°C) and injection pressures (70-120 Mpa) can be controlled with accuracy by machines. Automation in the production of acrylic by molding lowers human error and enhances the cycle times.

3D Printing and Prototyping

The molds in the acrylic prototype are accomplished by 3D printing within a limited time. This allows the engineers to carry out experimentation with designs and optimization of molds before the production is done in full. Acrylic plastic molding is faster and cheaper due to the quick prototyping.

Sustainable Materials

It is becoming a norm to recycle the acrylic waste and develop materials that are friendly to the environment. Pellets recycled in the production of acrylic products under the injection molding process will result in a reduced environmental impact, though it will not impact the quality of the product.

Improved Product Quality

In the future, there will be increased optical clarity (>90 percent light transmission), surface finish, and dimensional controls (+-0.1 mm) in what is termed acrylic molding. This strengthens products, making them clearer and more precise.

Industry Growth

With the growing need for durable, lightweight, and clear products, the market will be broadening on the activities of molding acrylic in the automotive, medical, electronic, and consumer goods sectors.

Through technology and sustainability adoption, acrylic injection molding will continue to be one of the manufacturing processes used in high-quality and efficient production.

Sincere Tech: Your Reliable Provider of Acrylic Injection Molding.

Sincere Tech (Plas.co) offers services of precision plastic molding and acrylic injection molding, which can be trusted. We have strong, accurate, and appealing parts, which are guaranteed by our high-technology and skilled workforce. We deal with custom-made acrylic molds and solutions that we make according to your design specifications.

Wholesome and Trustworthy Solutions.

We perform one-stop shopping prototype and product design up to large-scale production. You will be handling high-quality, durable, and reliable parts in our hands with our experience in acrylic molding and molding acrylic.

Reason to select Sincere Tech (Plas.co)?

The examples of our work can be viewed at https://plas.co. If you are seeking the best in terms of quality, precision, and good service, then Sincere Tech (Plas.co) is your partner when you are in search of the best in molding solutions.

Conclusion

Acrylic molding and acrylic injection molding are essential processes in the current production. They provide quality, long-lasting, and fashionable products that can be used in most industries. It is efficient and reliable, starting with the design of acrylic molds, to the creation of the consistent parts.

When manufacturers adhere to the best practices and select the appropriate partner, high-quality products can be produced with the help of the use of molding acrylic. The further maturation of technology means that acrylic injection molding will be one of the most important in the development of innovative, accurate, and aesthetic products.