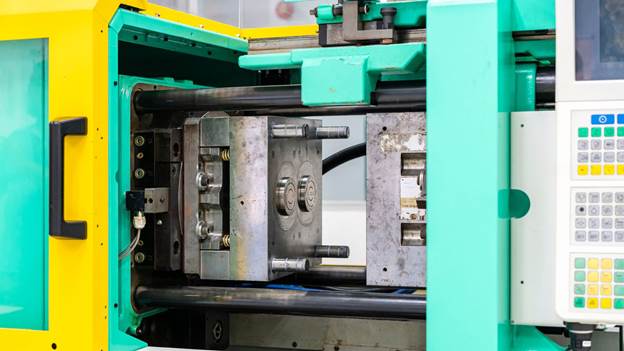

Den moderne produktion handler om effektivitet og præcision. Nogle af de teknikker, der er i brug, omfatter gasassisteret sprøjtestøbning. Gasassisteret sprøjtestøbning er en teknologisk produktionsmetode, der hjælper med at producere lette, holdbare og komplekse plastdele. De hule sektioner skabes ved at injicere formen med inert gas, hvilket reducerer mængden af anvendt materiale og også forkorter cyklustiden.

Resultatet af dette er øget dimensionel præcision, mindre forvrængning og mulighed for at lave innovative designs. Sprøjtestøbning med gasassistance er nyttig i bilindustrien, møbelindustrien, elektronikindustrien og forbrugerproduktindustrien, hvor der er behov for omkostningseffektiv produktion med høj kvalitet. Pålidelige leverandører af sprøjtestøbning med sentinelgasassistance er sikret et regelmæssigt resultat. Med den fremherskende produktion gør de fleste producenter brug af sprøjtestøbte produkter, der hjælpes af brugen af gas, hvilket giver producenterne mulighed for at opnå effektivitet, styrke og æstetik.

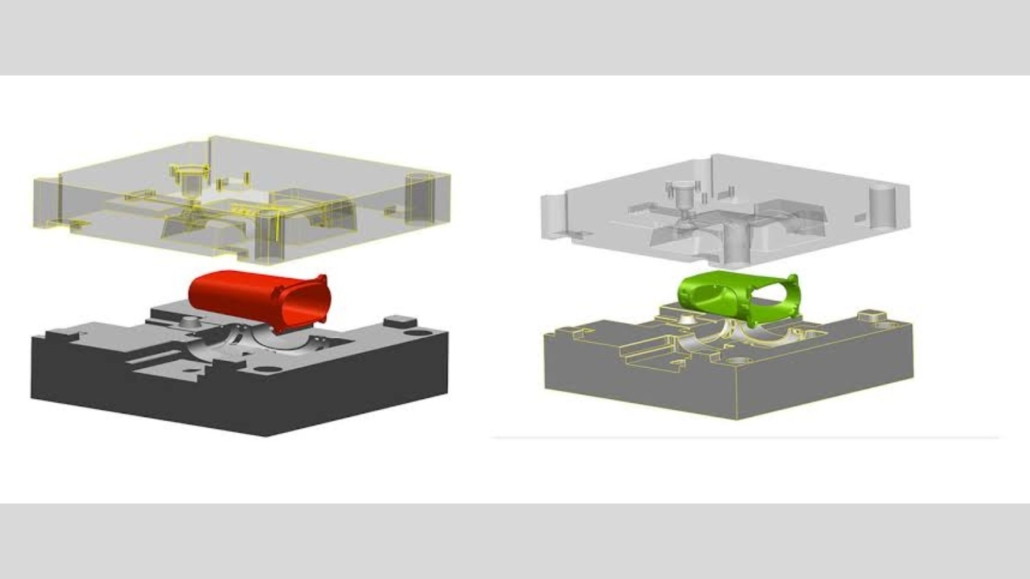

Hvad er gasassisteret sprøjtestøbning?

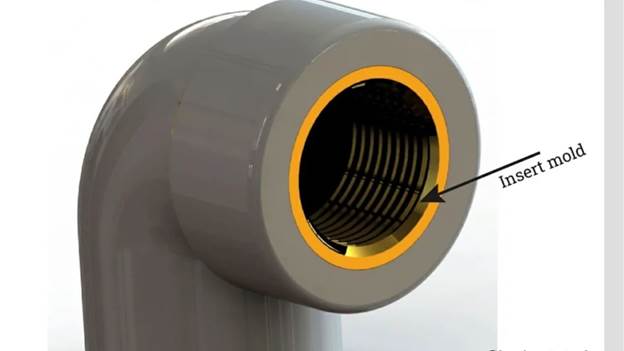

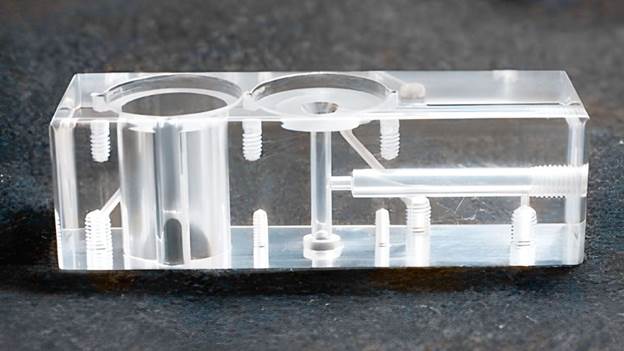

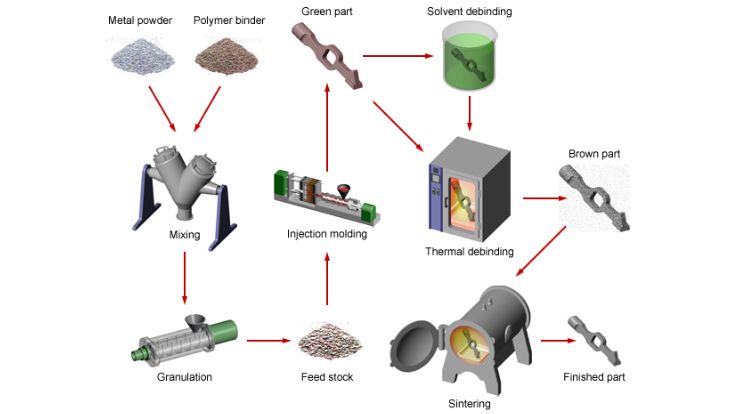

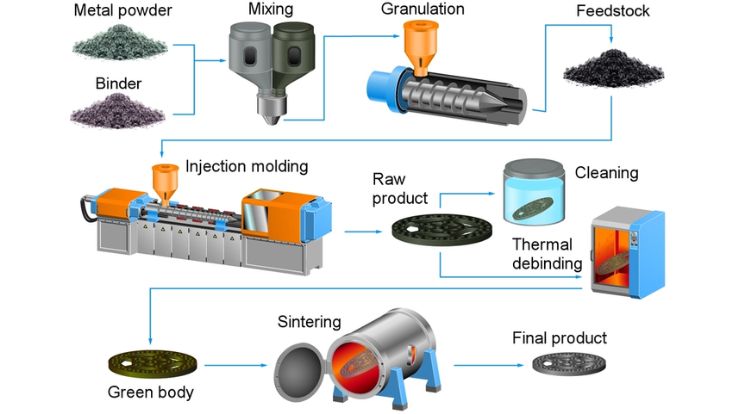

Gasassistance sprøjtestøbning er den proces, hvor inert gas (normalt nitrogen) sprøjtes ind i formen under indsprøjtningen af plasten. Gassen tvinger den varme plast mod komponentens tynde vægge eller hulrum og skaber et hulrum indeni. Teknikken sparer materiale, øger nøjagtigheden i dimensionerne og minimerer skævheder.

Processen er mest hensigtsmæssig i de sektioner, der er tykke, eller hvis sektioner har lange strømningsveje. Den bruges i vid udstrækning til fremstilling af biler, møbler og forbrugerprodukter. Kvaliteten og pålideligheden sikres ved at vælge passende leverandører af gasassisteret sprøjtestøbning.

Drift af gasassisteret sprøjtestøbning

Det starter ligesom den konventionelle sprøjtestøbning, hvor plast sprøjtes ind i en form. Når formhulrummet er delvist fyldt, sprøjtes der gas under tryk ind i nogle af områderne. Denne gas gør, at den flydende plast presses udad og danner hule kanaler, ls, men gør overfladen hård.

Metoden resulterer i reduceret spænding i tykkere dele, ingen sænkninger og ensartet vægtykkelse. Resultatet er et emne af høj kvalitet, som er mere formstabilt, let og stærkt. Det er egenskaber, som er funktionelle og æstetiske for producenterne af produkter som f.eks. gasassisteret sprøjtestøbning.

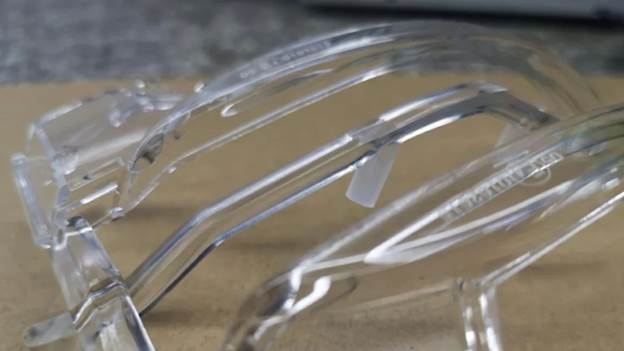

Anvendelser af gasassisteret sprøjtestøbning: Gasassisteret sprøjtestøbning er en smidig fremstillingsteknik, som anvendes i de fleste industrier. Hule eller indviklede former kan skabes med mindre indsats, hvilket gør den passende til både nyttige og dekorative formål.

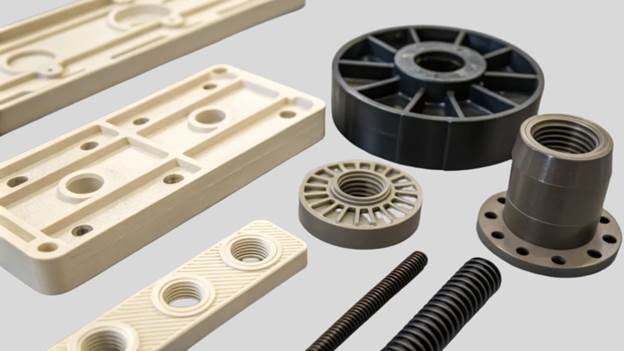

Automotive Industriel gasassisteret sprøjtestøbning af indvendige paneler, dørhåndtag og strukturelle dele udføres af bilproducenter. Proceduren gør det let uden at miste den styrke, der er forbundet med brændstofeffektivitet og ydeevne.

Møbler og forbrugerprodukter

Den gasassisterede sprøjtestøbning bruges til at skabe hule sektioner, der skabes i plastdele til møbler, apparater og værktøj. De lette komponenter som stolerygge, håndtag og huse udgør en effektiv produktionsmetode.

Industrielt udstyr

Robotterne og maskinerne har som regel brug for stærke plastdele af en vis størrelse. Fremstillede produkter baseret på gasassisteret sprøjtestøbning har holdbarhed, standard vægtykkelse og modstandsdygtighed over for vridning.

Elektronik Gasassisteret sprøjtestøbning bruges til fremstilling af forbrugerelektronik, værktøjskasser og andre enheder, der kræver et stærkt og attraktivt udseende, og som derfor har et lavt materialeforbrug.

Andre anvendelser

Det bruges også til sportsudstyr, legetøj og indpakning. Producenterne benytter sig af leverandører af gasassisteret sprøjtestøbning, som har mulighed for at producere dele af den givne størrelse og kvalitet.

Efter at have kendt sådanne anvendelser kan virksomheder opleve den fulde fordel ved gasassisteret sprøjtestøbning til at producere lette og prisbillige produkter.

Anvendt materiale

Termoplast: Termoplast er det mest anvendte materiale i gasassisteret sprøjtestøbning. Nogle materialer kan let bearbejdes og bindes i den gasassisterede proces, f.eks. polypropylen (PP), polyethylen (PE), ABS og polycarbonat (PC). Disse plasttyper er velegnede til fremstilling af lette og stærke sprøjtestøbte produkter.

Forstærket plast: Glasforstærket plast af nylon eller polypropylen er desuden hårdt og stift. De bruges i områder, hvor komponenten udsættes for en høj grad af stress eller belastning, og vil derfor klare sig godt sammen med de bil- eller industridele, der produceres under gasassisteret sprøjtestøbning.

Specialiserede polymerer: I nogle tilfælde bruges specialpolymerer, der er kendetegnet ved enten høj varmebestandighed eller kemisk resistens. Disse materialer bestemmer produktets krav i specifikke termer, der sikrer dets ydeevne og levetid. Inddragelsen af gasassisteret sprøjtestøbning, som har fungeret i industrien før, vil hjælpe med at vælge det rigtige materiale til enhver anvendelse.

Valg af materiale: Det anvendte medie skal have fremragende flydeegenskaber, termisk stabilitet og kompatibilitet med gasindsprøjtning. Det rigtige materialevalg er helt afgørende for at reducere fejlene, styrken og effektiviteten af de dele, der bruges i processen med gasassisteret sprøjtestøbning.

Teknikker

Gensidig indsprøjtning ved hjælp af gaskanaler

I den laves hule dele ved at pumpe ind i formen i nogle områder. Det sparer på materialeforbruget og giver ensartethed i væggens tykkelse. Det bruges også i vid udstrækning til produktion af lette og hårde kompositter - assisteret sprøjtestøbning.

Tilpasningsbar gastryksregulator

Gastrykket kan også justeres i støbeprocessen for at manipulere materialets flow på en bedre måde. Dette forhindrer synkemærker og forbedrer overfladefinishen og gør kunsten stærkere. Og vigtigst af alt er tilfælde af gasassisteret støbning af høj kvalitet. sprøjtestøbt produkter.

Sekventiel gasindsprøjtning

Sekventiel gasindsprøjtning indebærer indsprøjtning af gas på forskellige stadier af støbeprocessen. Proceduren vil garantere optimering af materialestrømmen, der antager form af en komplet X-form, og reduktion af antallet af defekter. Man bør også henvende sig til leverandørerne, da de er fortrolige med gasassisteret sprøjtestøbning, så det kan gøres præcist.

Topmoderne kølemetoder

Gasassisteret støbning med avancerede kølesystemer er praktisk til hurtig størkning af komponenter og reduktion af cyklustiden. Det fremmer produktiviteten, og det hindrer ikke emnets design.

Fordele ved gasassisteret sprøjtestøbning

Når man sammenligner den traditionelle støbning med den såkaldte gasassisterede sprøjtestøbning, er der flere fordele:

Besparelser på materialer

De hule sektioner bruger også mindre plast og reducerer både udgifter og miljøpåvirkning.

Mindre vridning og synkemærker

Gasassisteret støbning minimerer de fleste af de almindelige fejl, som f.eks. synkemærker eller overfladedeformationer, ved hjælp af en jævn fordeling af materialet.

Lighter-dele

Der findes hule strukturer, som gør det muligt at skabe lette komponenter uden at reducere styrken.

Hurtigere produktion

Sammen med et mindre materialeforbrug og et bedre flow følger en reduktion af cyklustiderne, hvilket er mere acceptabelt for producenterne.

Forbedret spillerum i designet

Det er muligt at skabe komplekse former samt at tilføje tykkere dele uden at reducere kvaliteten eller gøre det dyrere.

Overvejelser om design

Assisteret sprøjtestøbning udviklet med gas skal også planlægges godt for at maksimere processen.

Materialevalg Alle plastmaterialer kan gasstøbes. Designerne bør bruge materialer, der er lette at flyde og binde under gasindsprøjtning.

Væggens tykkelse

Væggene skal være lige tykke. De åbne rum bør placeres på strategiske steder for at skabe styrke og funktionalitet.

Placering af gaskanalen: Placeringen af gaskanalen er meget vigtig. Når de lægges forkert, kan de efterlade halvfyldte fyldninger, svage punkter eller æstetiske defekter.

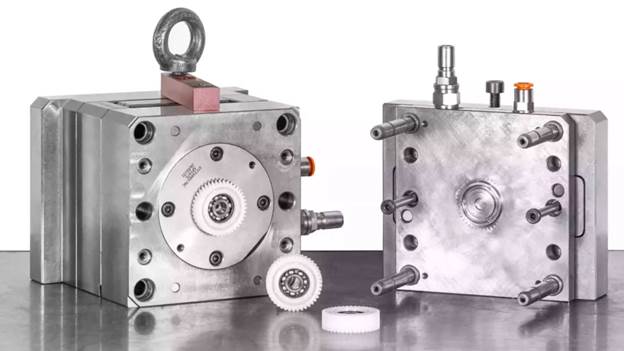

Formdesign

Der skal være mulighed for passage af plast og gas til formene. Portene skal være godt ventilerede og designet til at sikre, at produktionen er effektiv, og at fejlene minimeres.

Disse designspecifikationer er det sikre middel til resultater af høj kvalitet og pålidelighed ved gasassisteret sprøjtestøbning.

Omkostnings- og produktionseffektivitet

Omkostninger og produktionseffektivitet Gasassisteret sprøjtestøbning er meget økonomisk sammenlignet med de traditionelle processer, hvad angår formbetingelser, udgifter og hastigheden, hvormed produkterne produceres. Det sparer på materialeomkostningerne, fordi delene er hule rum, der er gode og økonomiske.

Processen gør det muligt for smeltet plast at flyde frit, og det sparer tid på afkøling. Det gør det muligt for producenterne at producere dele hurtigere uden at gå på kompromis med kvaliteten. Virksomheder, der fremstiller emnerne ved hjælp af gasassisterede sprøjtestøbte produkter, har den fordel, at det går hurtigere, og at resultaterne er ensartede.

Samarbejdet med de eksperter, der leverer den gasassisterede sprøjtestøbningsproces, reducerer antallet af manuelle håndteringer og samlinger, hvilket også reducerer lønomkostningerne. Det er meget effektivt med hensyn til at spare materiale, mindske cyklusserne og fejlene, selv om formene er mere komplicerede i starten.

Almindelige fejl at undgå

Der er mange fejl, som kan påvirke produktets kvalitet og effektivitet ved gasassisteret sprøjtestøbning. Spørgsmålet om forkert gastryk er det mest almindelige problem. Over- eller undertryk kan føre til deformation af komponenter eller defekter.

En anden fejl er dårlig kanalisering af gasser. Enhver fejljustering kan resultere i delvis fyldning eller glatte vægge, som vil gøre produkter, der er fyldt med gasassisteret sprøjtestøbning, svage.

Problemet med uoverensstemmelse mellem de anvendte materialer er også ret almindeligt. Nogle plastmaterialer har ikke reageret godt på gasassisterede processer, hvilket har ført til defekter eller dårlig limning.

Det kan også være problematisk at ignorere designretningslinjer, f.eks. vægtykkelse og delens geometri. Komponenter kan bøjes, synke eller blive stressede.

Følgende fejl kan elimineres ved at samarbejde med erfarne leverandører af gasassisteret sprøjtestøbning, ved at tage hensyn til de relevante retningslinjer for design og proces og ved at sikre en konstant produktion af høj kvalitet.

Identificering af de rigtige leverandører af gasassisteret sprøjtestøbning

En vellykket gasassisteret sprøjtestøbning afhænger af, hvilken partner man vælger. Arbejdet med veletablerede leverandører er en garanti for kvalitetsdele og uafbrudte produktionsprocesser.

Vælg gasassistenten sprøjtestøbning leverandører, der har en succesfuld historie med at fremstille gasassisterede sprøjtestøbte produkter af samme art, som ligner dit projekt. De kan undgå fejl og forbedre deres effektivitet ved hjælp af deres erfaring med design af formene og valg af det anvendte materiale.

Leverandøren bør også levere en procesoptimeringsguide til processen, f.eks. gastryk, positioneringskanaler og cyklustider. Det kan bruges til at reducere spild og unøjagtigheder i produktionen.

Leverandører af kvalitet investerer i kvalitetskontrolsystemer og nyt udstyr. De giver sikre resultater, en hurtigere hastighed og omkostningseffektivitet i gasassisterede sprøjtestøbningsprogrammer.

Fremtidige tendenser

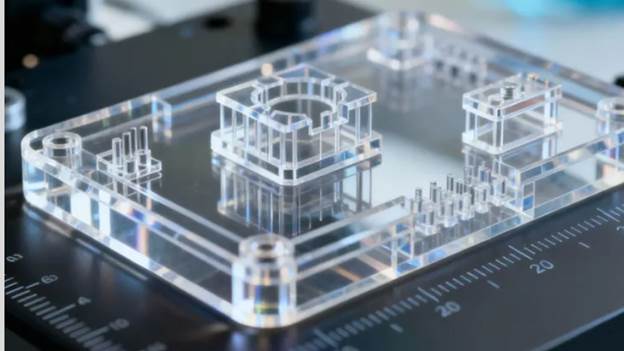

Det er fremtiden for gasassisteret sprøjtestøbning, som afhænger af innovation og effektivitet. Producenterne ser på nyere, stærkere, lettere og mere holdbare materialer. Det er teknologier, der resulterer i gasassisterede sprøjtestøbte kvalitetsprodukter.

Den anden vigtige tendens er automatiseringstendensen. Robotter og AI-systemer står i stigende grad for gasindsprøjtningen og formhåndteringen, og de udrydder fejlene og gør produktionsprocessen hurtigere. Gasleverandørerne med erfaring inden for sprøjtestøbning tager også teknologierne til sig for at holde trit med konkurrenterne.

Bæredygtighed er også i fokus. Forbruget af færre materialer, genbrug af plast og energibesparende produktion er miljøvenlige produktionselementer i fremstillingen af miljøvenlig sprøjtestøbning, der betegnes som gasassisteret sprøjtestøbning.

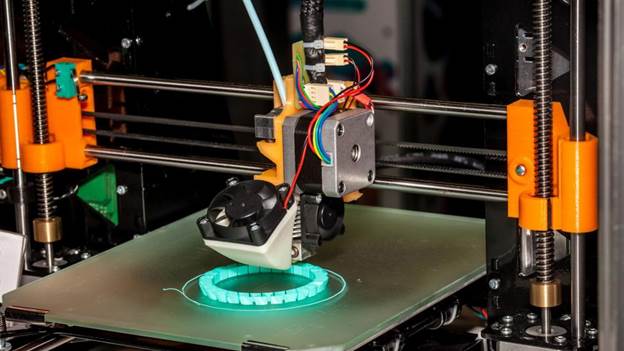

Dette forbedres med tilføjelsen af 3D-print, som udvider mulighederne for hurtig prototyping og serieproduktion. Det hjælper designere med at eksperimentere med komplekse former til lave omkostninger og på kortest mulig tid; på den måde er gasassisteret sprøjtestøbning mere produktiv i moderne produktion.

Konklusion

Gas-assisteret sprøjtestøbning kan tilbyde producenterne en levedygtig tilgang til at producere lette, komplicerede og robuste komponenter. Virksomhederne er i stand til at træffe den rigtige beslutning, da de ved, hvordan det fungerer, hvilke fordele det giver, og hvordan det skal designes. Valget af pålidelige leverandører af gasassisteret sprøjtestøbning vil betyde, at standarden for gasassisterede sprøjtestøbte produkter vil være den samme på tværs af brancherne. Faldet i mængden af anvendt materiale resulterer i en stigning i produktionshastigheden og muligheden for at foretage ændringer i design, hvilket øger populariteten af teknikken, der bliver en ret nødvendig form for moderne produktion.