La production moderne est axée sur l'efficacité et la précision. Parmi les techniques utilisées figure le moulage par injection assistée au gaz. Le moulage par injection assistée au gaz est une méthode de production technologique qui permet de produire des pièces en plastique légères, durables et complexes. Les sections creuses sont créées en injectant du gaz inerte dans le moule, ce qui réduit la quantité de matière utilisée et la durée du cycle.

Il en résulte une augmentation de la précision dimensionnelle, une réduction des distorsions et la possibilité de réaliser des conceptions innovantes. Le moulage par injection de gaz est utile dans l'industrie automobile, l'industrie du meuble, l'industrie électronique et l'industrie des produits de consommation, où une production rentable et de haute qualité est nécessaire. Les fournisseurs fiables de moulage par injection de gaz sentinelle sont assurés de fournir un résultat régulier. Avec la production actuelle, la plupart des fabricants utilisent des produits moulés par injection qui sont assistés par l'utilisation de gaz, ce qui permet aux fabricants d'atteindre l'efficacité, la solidité et l'esthétisme.

Qu'est-ce que le moulage par injection assisté par gaz ?

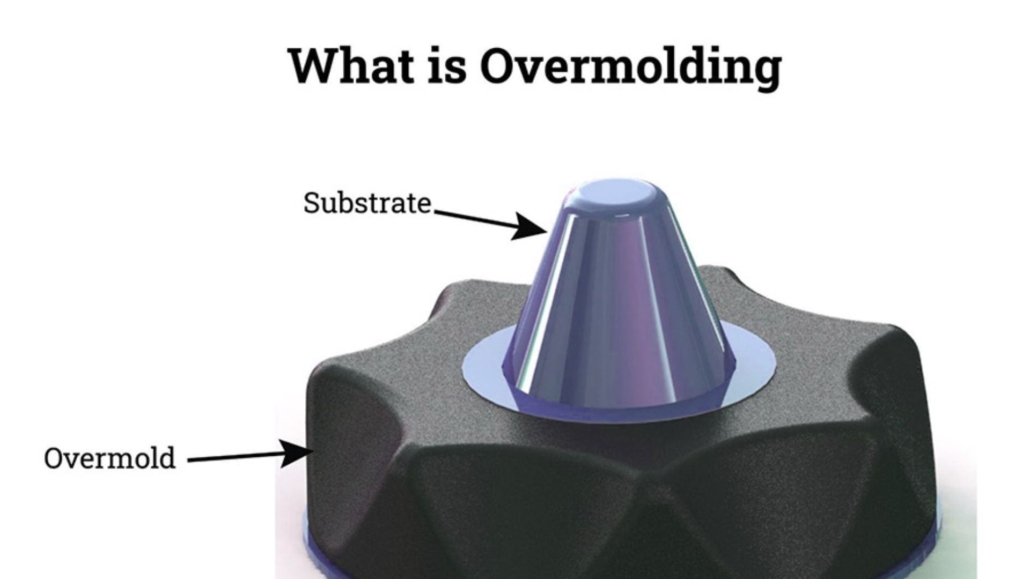

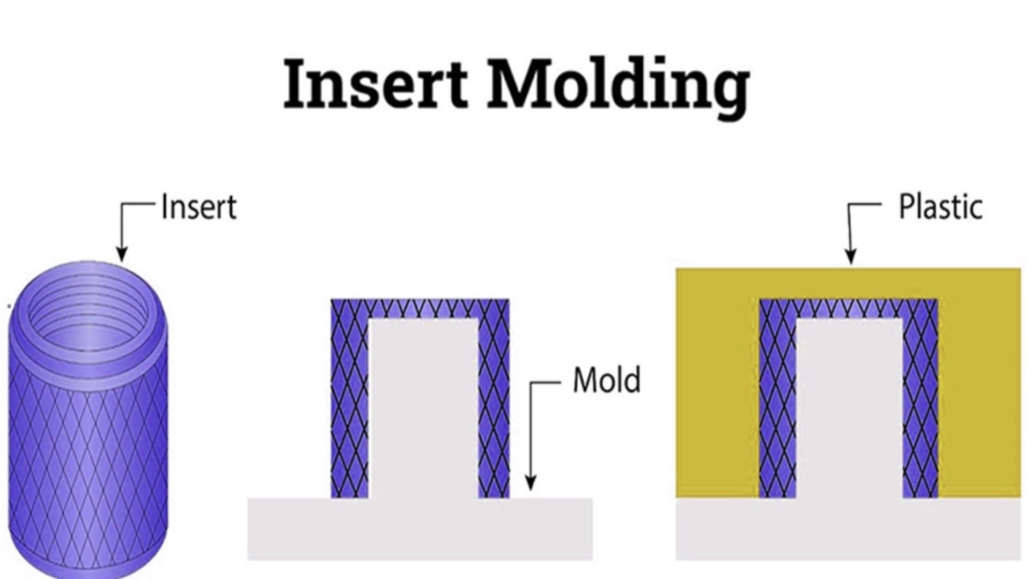

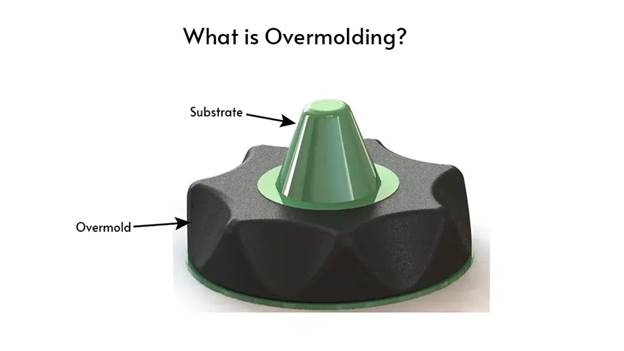

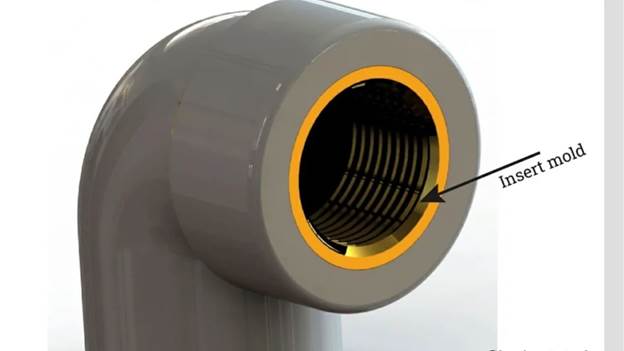

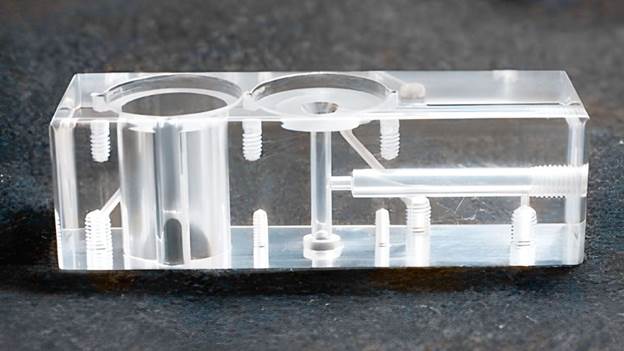

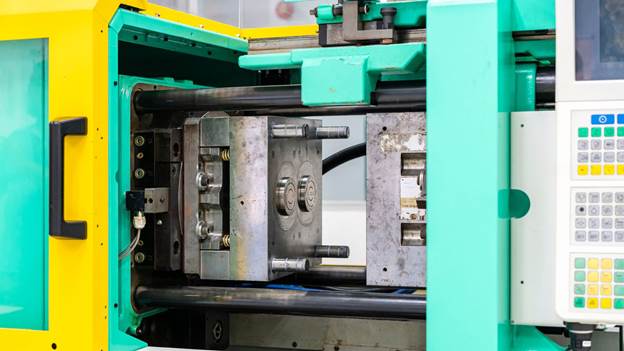

Assistance au gaz moulage par injection est le processus par lequel un gaz inerte (généralement de l'azote) est injecté dans le moule pendant l'injection du plastique. Le gaz force le plastique chaud contre les parois minces ou le creux de la pièce, créant ainsi un creux à l'intérieur de celle-ci. Cette technique permet d'économiser des matériaux, d'augmenter la précision des dimensions et de minimiser les déformations.

Le procédé est plus approprié dans les sections épaisses ou dont les sections ont de longues voies d'écoulement. Il est largement utilisé dans la fabrication d'automobiles, de meubles et de produits de consommation. La qualité et la fiabilité seront assurées par le choix de fournisseurs appropriés de moulage par injection assistée par gaz.

Fonctionnement du moulage par injection assistée par gaz

Il commence comme le moulage par injection conventionnel, c'est-à-dire que le plastique est injecté dans un moule. Une fois la cavité du moule partiellement remplie, du gaz sous pression est injecté dans certaines zones. Ce gaz pousse le plastique liquide vers l'extérieur pour former des canaux creux, ls mais rend la surface dure.

Cette méthode permet de réduire les contraintes dans les pièces plus épaisses, d'éviter les pertes et d'uniformiser l'épaisseur des parois. Il en résulte une pièce de haute qualité, plus stable sur le plan dimensionnel, plus légère et plus résistante. Ces caractéristiques sont fonctionnelles et esthétiques pour les fabricants de produits tels que le moulage par injection assistée par gaz.

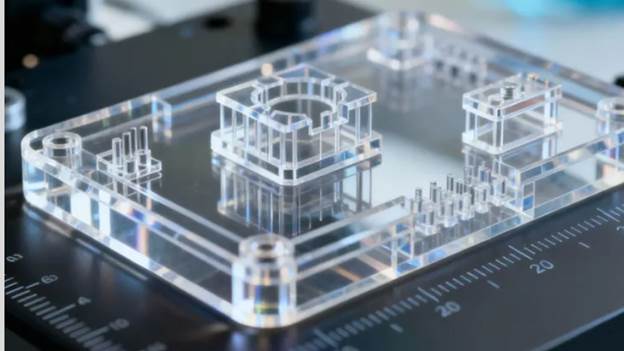

Applications du moulage par injection assistée par gaz : Le moulage par injection assistée par gaz est une technique de fabrication souple qui est utilisée dans la plupart des industries. Des formes creuses ou complexes peuvent être créées avec moins d'effort, ce qui permet de l'utiliser à des fins utiles et décoratives.

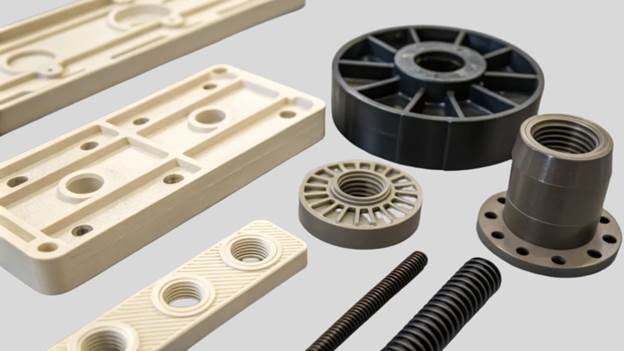

Automobile Les constructeurs automobiles procèdent au moulage par injection assistée par gaz industriel des panneaux intérieurs, des poignées de porte et des pièces structurelles. La procédure permet de les alléger sans perdre la résistance qui est liée à l'efficacité énergétique et à la performance.

Meubles et produits de consommation

Le moulage par injection assisté par gaz est utilisé pour créer des sections creuses dans les pièces en plastique de meubles, d'appareils et d'outils. Les composants légers tels que les dossiers de chaises, les poignées et les boîtiers constituent un mode de production efficace.

Équipement industriel

Les robots et les machines ont généralement besoin de pièces en plastique solides d'une certaine taille. Les produits fabriqués à partir du moulage par injection assistée par gaz sont durables, ont une épaisseur de paroi standard et résistent au gauchissement.

Électronique Le moulage par injection assisté par gaz est utilisé dans la fabrication d'appareils électroniques grand public, de boîtiers d'outils et d'autres appareils qui doivent avoir une apparence solide et attrayante, tout en consommant peu de matériaux.

Autres applications

Il est également utilisé dans les équipements sportifs, les jouets et les emballages. Les fabricants ont recours aux services des fournisseurs de moulage par injection assistée par gaz qui ont la possibilité de produire des pièces de la taille et de la qualité données.

Ces applications étant connues, les entreprises peuvent profiter pleinement des avantages du moulage par injection de gaz pour fabriquer des produits légers et abordables.

Matériau utilisé

Thermoplastiques : Les thermoplastiques sont les matériaux les plus couramment utilisés dans le moulage par injection assistée par gaz. Certains matériaux peuvent être facilement travaillés et collés dans le processus assisté par gaz, comme le polypropylène (PP), le polyéthylène (PE), l'ABS et le polycarbonate (PC). Ces plastiques conviennent à la fabrication de produits moulés par injection légers et résistants.

Plastique renforcé : Les plastiques renforcés de verre en nylon ou en polypropylène sont en outre résistants et rigides. Ils sont utilisés dans les domaines qui exposent le composant à un degré élevé de contrainte ou de charge et conviennent donc parfaitement aux pièces automobiles ou industrielles produites lors du moulage par injection assistée par gaz.

Polymères spéciaux : Dans certains cas, des polymères spéciaux caractérisés par une résistance élevée à la chaleur ou aux produits chimiques sont utilisés. Ces matériaux déterminent les exigences du produit en termes spécifiques qui garantissent sa performance et sa longévité. L'inclusion du moulage par injection assisté par gaz, qui a déjà fonctionné dans l'industrie, aidera à choisir le bon matériau à utiliser dans n'importe quelle application.

Sélection des matériaux : Le fluide utilisé doit présenter d'excellentes caractéristiques d'écoulement, de stabilité thermique et de compatibilité avec l'injection de gaz. La sélection adéquate des matériaux est essentielle pour réduire les défauts, la résistance et l'efficacité des pièces utilisées dans le processus de moulage par injection assistée par gaz.

Techniques

Injection réciproque à l'aide de canaux à gaz

Les pièces creuses sont fabriquées par pompage dans le moule à certains endroits. Cette technique permet de réduire la consommation de matériaux et d'uniformiser l'épaisseur des parois. Il est également largement utilisé dans la production de composites légers et résistants - moulage par injection assistée.

Régulateur de pression de gaz adaptable

La pression du gaz peut également être ajustée au cours du processus de moulage afin d'améliorer l'écoulement du matériau. Cela permet d'éviter les marques d'enfoncement, d'améliorer la finition de la surface et de renforcer l'art. Et surtout, les cas de moulage assisté par gaz de haute qualité permettent d'améliorer la qualité de l'art. moulé par injection produits.

Injection séquentielle de gaz

L'injection séquentielle de gaz consiste à injecter du gaz à différents stades du processus de moulage. Cette procédure garantira l'optimisation du flux de matériaux, qui prendra la forme d'un X complet, et la réduction du nombre de défauts. Il convient également de s'adresser aux fournisseurs, qui connaissent bien le moulage par injection de gaz, de sorte qu'il peut être réalisé avec précision.

Méthodes de refroidissement de pointe

Le moulage assisté par gaz avec des systèmes de refroidissement avancés est pratique pour la solidification des composants et la réduction rapide du temps de cycle. Cela favorise la productivité et n'entrave pas la conception de la pièce.

Avantages du moulage par injection assistée par gaz

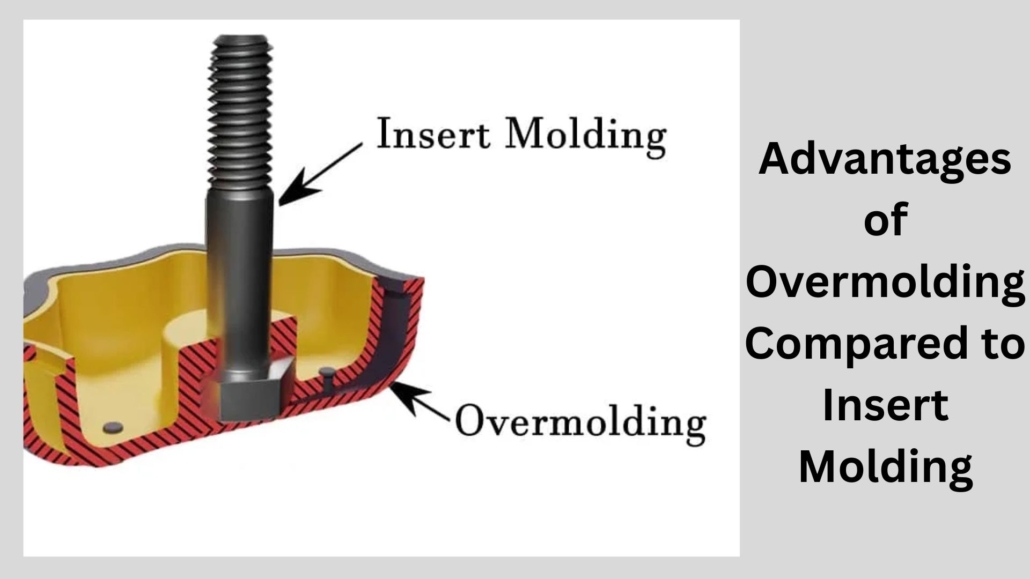

Si l'on compare le moulage traditionnel et le moulage par injection assisté par gaz, plusieurs avantages peuvent être relevés :

Économies de matériaux

Les sections creuses consomment également moins de plastique et réduisent à la fois les dépenses et l'impact sur l'environnement.

Moins de déformation et de marques d'affaissement

Le moulage assisté par gaz minimise la plupart des défauts courants, tels que les marques d'enfoncement ou les déformations de surface, grâce à la répartition uniforme du matériau.

Pièces pour briquets

Des structures creuses sont disponibles pour permettre la création de composants légers sans réduction de la résistance.

Une production plus rapide

La réduction de la consommation de matériaux et l'amélioration des flux s'accompagnent d'une réduction des temps de cycle, ce qui est plus acceptable pour les fabricants.

Amélioration de la marge de manœuvre en matière de conception

Il est possible de créer des formes complexes, ainsi que d'ajouter des pièces plus épaisses sans réduire la qualité ou le coût.

Considérations relatives à la conception

Le moulage par injection assistée développé avec du gaz doit également être bien planifié afin de maximiser le processus.

Sélection des matériaux Toutes les matières plastiques peuvent être moulées par injection de gaz. Les concepteurs doivent utiliser des matériaux qui s'écoulent et se lient facilement sous l'effet de l'injection de gaz.

Épaisseur de la paroi

Les murs doivent être d'épaisseur égale. Les espaces ouverts doivent être placés à des endroits stratégiques pour créer de la force et de la fonctionnalité.

Placement du canal de gaz : L'emplacement du canal de gaz est le plus important. Lorsqu'ils sont mal placés, ils peuvent laisser des obturations à moitié remplies, des points faibles ou des défauts esthétiques.

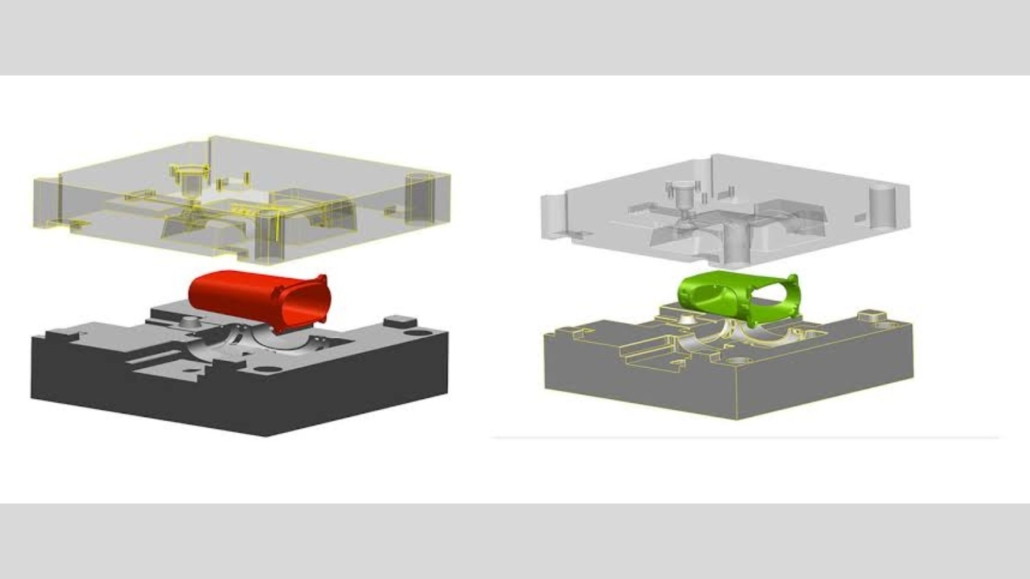

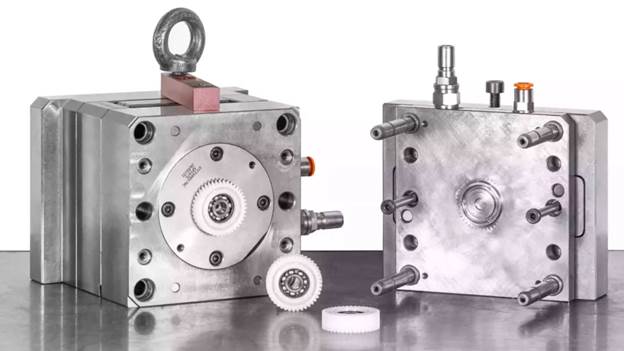

Conception des moules

Le passage du plastique et des gaz doit être possible vers les moules. Les portes doivent être bien ventilées et conçues de manière à assurer une production efficace et à minimiser les défauts.

Ces spécifications de conception sont les garants de la qualité des résultats et de la fiabilité du moulage par injection avec assistance gazeuse.

Coût et efficacité de la production

Coût et efficacité de la production Le moulage par injection assistée au gaz est très économique par rapport aux procédés traditionnels en termes de conditions de moulage, de dépenses et de vitesse de production des produits. Il permet d'économiser sur le coût des matériaux car les pièces sont des espaces creux qui sont bons et économiques.

Le processus permet au plastique fondu de s'écouler librement, ce qui permet de gagner du temps lors du refroidissement. Les fabricants peuvent ainsi produire des pièces plus rapidement sans compromettre la qualité. Les entreprises qui fabriquent des articles par le biais de produits moulés par injection assistée par gaz ont l'avantage d'être plus rapides et d'obtenir des résultats cohérents.

La coopération avec les experts qui fournissent le processus de moulage par injection assisté par gaz réduit le nombre de manipulations manuelles et de collectes, ce qui réduit également les coûts de main-d'œuvre. C'est très efficace en termes d'économie de matériaux, de réduction des cycles et des défauts, même si les moules sont plus compliqués au départ.

Les erreurs courantes à éviter

Les erreurs qui peuvent nuire à la qualité et à l'efficacité du produit sont nombreuses dans le cas du moulage par injection assisté par gaz. La question de la mauvaise pression du gaz est le problème le plus courant. La surpression ou la sous-pression peut entraîner une déformation des composants ou des défauts.

Une autre erreur consiste à mal canaliser les gaz. Tout désalignement peut entraîner un remplissage partiel ou des parois lisses qui rendront les produits remplis à l'aide du moulage par injection assisté par gaz médiocres.

Le problème de l'inadéquation des matériaux utilisés est également assez courant. Certains plastiques ne réagissent pas bien aux procédés assistés par gaz, ce qui entraîne des défauts ou un mauvais collage.

Le fait d'ignorer les directives de conception, c'est-à-dire l'épaisseur de la paroi et la géométrie de la pièce, peut également poser problème. Les composants peuvent se plier, s'enfoncer ou subir des contraintes.

Les erreurs suivantes peuvent être éliminées en collaborant avec des fournisseurs expérimentés dans le domaine du moulage par injection assistée par gaz, en tenant compte des lignes directrices appropriées en matière de conception et de processus et en garantissant une production de haute qualité de manière constante.

Identification des fournisseurs de moulage par injection avec assistance gazeuse

La réussite du moulage par injection avec assistance gazeuse dépend du choix du bon partenaire. Les efforts déployés avec des fournisseurs bien établis sont l'assurance de pièces de qualité et de processus de fabrication ininterrompus.

Sélectionner l'assistance au gaz moulage par injection les fournisseurs qui ont une expérience réussie dans la fabrication de produits moulés par injection d'assistance au gaz de même nature, similaires à votre projet. Ils peuvent éviter les défauts et améliorer leur efficacité grâce à leur expérience dans la conception des moules et la sélection des matériaux utilisés.

Le fournisseur doit également fournir un guide d'optimisation du processus, notamment en ce qui concerne la pression du gaz, les canaux de positionnement et les temps de cycle. Ce guide peut être utilisé pour réduire les déchets et les imprécisions dans la production.

Les fournisseurs de qualité investissent dans des systèmes de contrôle de la qualité et dans de nouveaux équipements. Ils garantissent des résultats, une cadence plus rapide et un bon rapport coût-efficacité dans les programmes de moulage par injection assistée par gaz.

Tendances futures

C'est l'avenir du moulage par injection assisté par gaz, qui dépend des innovations et de l'efficacité. Les fabricants s'intéressent à des matériaux nouveaux, plus résistants, plus légers et plus durables. Ces technologies permettent de fabriquer des produits moulés par injection assistée au gaz de qualité.

L'autre tendance importante est celle de l'automatisation. Les robots et les systèmes d'intelligence artificielle sont de plus en plus souvent chargés de l'injection du gaz et de la manipulation des moules, ce qui permet d'éliminer les erreurs et d'accélérer le processus de production. Les fournisseurs de gaz qui ont de l'expérience dans le domaine du moulage par injection adoptent également ces technologies pour rester dans la course.

La durabilité est également prise en compte. La consommation d'une quantité moindre de matériaux, le recyclage du plastique et la production économe en énergie sont des éléments de fabrication respectueux de l'environnement dans la fabrication du moulage par injection écologique, appelé moulage par injection avec assistance gazeuse.

Cette évolution est renforcée par l'ajout de l'impression 3D, qui élargit les possibilités de prototypage rapide et de production par lots. Les concepteurs peuvent ainsi expérimenter des formes complexes à faible coût et dans les meilleurs délais ; le moulage par injection assistée au gaz est ainsi plus productif dans la production moderne.

Conclusion

Assisté par gaz moulage par injection peut offrir aux fabricants une approche viable pour produire des composants légers, complexes et robustes. Les entreprises sont en mesure de prendre la bonne décision, car elles connaissent son fonctionnement, ses avantages et la manière dont il convient de le concevoir. Le choix de fournisseurs fiables de moulage par injection assistée de gaz impliquerait que la norme des produits moulés par injection assistée de gaz serait la même dans toutes les industries. La diminution de la quantité de matériaux utilisés entraîne une augmentation de la vitesse de production et de la capacité à modifier les conceptions, ce qui accroît la popularité de la technique qui devient une forme assez nécessaire de la production moderne.