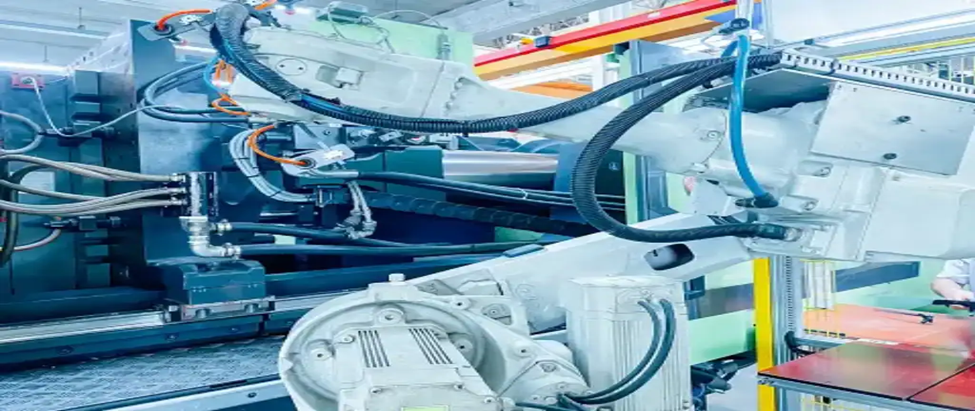

射出成形による部品製造は、現代産業の重要な構成要素である。射出成形は、私たちを取り巻く多くの製品の製造に使用されています。これは、強くて正確な部品の生産を助けるプロセスです。これらの部品は多くの分野で応用されている。求められる成形品の品質は年々上がっている。.

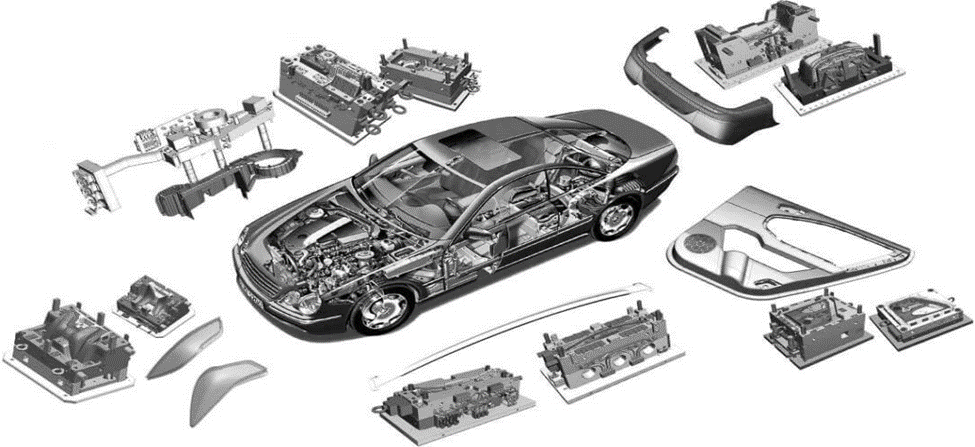

プラスチック射出成形部品が広く使われている背景には、耐久性と経済性がある。同じ形状の製品を大量に製造することができる。複雑なデザインもこの工程でうまく機能する。一方、射出成形金型部品は、これらの製品の成形と形成において重要である。適切な金型部品がなければ、プロセスはうまく進まない。.

射出成形の人気は、時間を節約できることにある。無駄も省ける。この方法は短サイクル生産を可能にする。これは、多くの産業が手放すことのできないものである。.

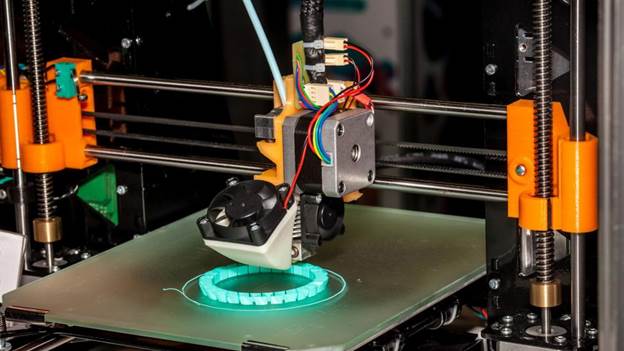

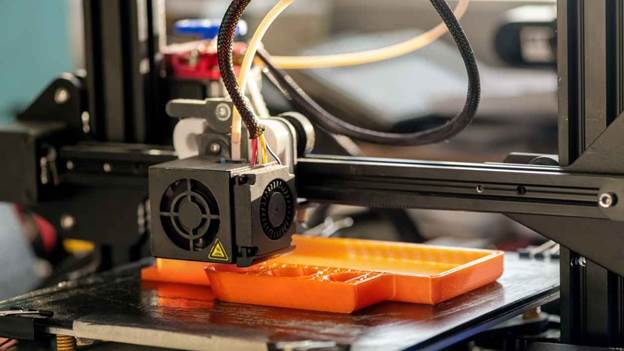

プラスチック射出成形プラスチック射出成形とは?

プラスチック 射出成形 とは生産工程のことである。大量にプラスチック製品が生産される。また、迅速で信頼性の高い手順でもある。どのような場合でも、同じ形と大きさの部品を製造することができます。.

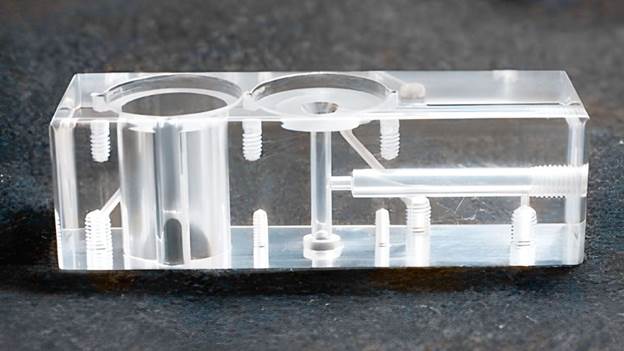

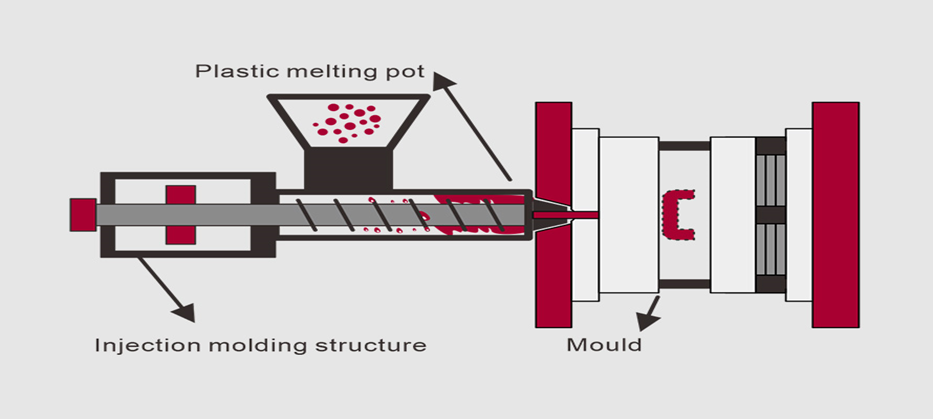

このプロセスでは、まずプラスチック材料が加熱される。プラスチックは柔らかくなり、溶ける。次に、液状のプラスチックを金型に挿入する。金型は特定の形状をしている。プラスチックが冷えると固形になる。この部品全体が金型から取り出される。.

プラスチック射出成形は、単純なものから複雑なものまで、様々な製品に利用されている。高い精度が得られます。また、材料の無駄も省ける。その理由は、時間とお金の無駄が減るので人気があることと関係がある。.

表1:射出成形金型の構成部品

| 金型部品 | 代表的な素材 | 寛容 | 表面仕上げ | 典型的なライフサイクル | 機能 |

| コア&キャビティ | 硬化鋼 / アルミニウム | ±0.01-0.03 mm | Ra 0.2-0.8 μm | >100万ショット以上 | 内部および外部の形状 |

| ランナー | スチール/アルミニウム | ±0.02 mm | Ra 0.4-0.6 μm | >50万ショット以上 | 溶融プラスチックをキャビティに流す |

| ゲート | スチール/アルミニウム | ±0.01 mm | Ra 0.2-0.5 μm | >50万ショット以上 | キャビティ内へのプラスチックの侵入をコントロール |

| 冷却チャンネル | 銅 / スチール | ±0.05 mm | Ra 0.4-0.6 μm | 連続 | 効率的に熱を取り除く |

| イジェクターピン | 硬化鋼 | ±0.005 mm | Ra 0.3-0.5 μm | >100万ショット以上 | 完成品を損傷することなく排出 |

| ベントスロット | スチール/アルミニウム | ±0.01 mm | Ra 0.2-0.4 μm | 連続 | 注入時に閉じ込められた空気を逃がす |

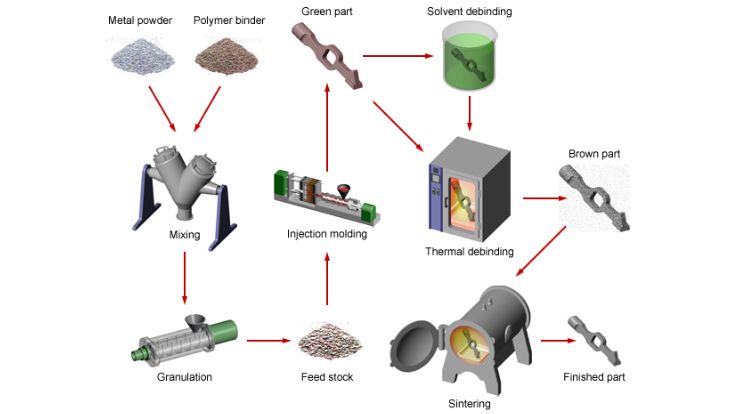

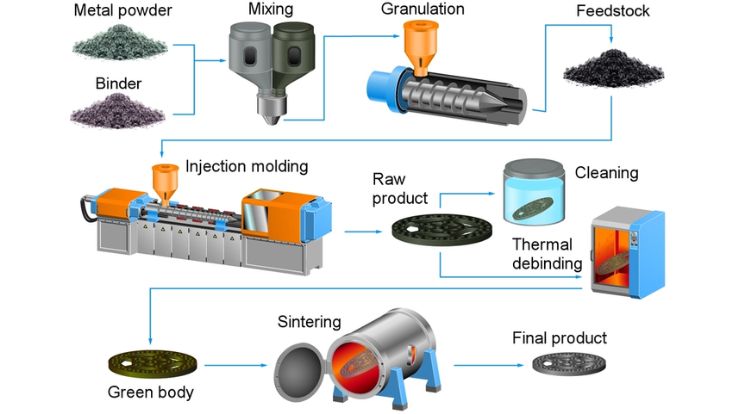

射出成形プロセスを知る

制御された精密な生産方法が射出成形技術である。高精度のプラスチック部品の生産に適用される。これは、段階的に行われる機能的な手順である。各段階には、いくつかのパラメータと数値があります。.

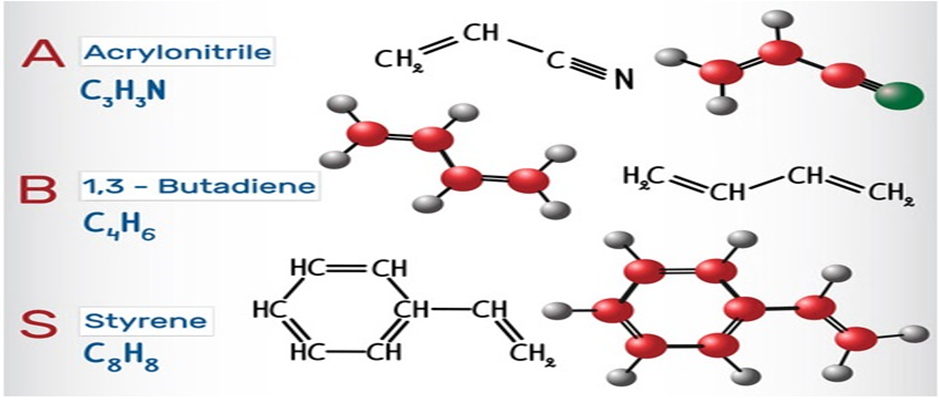

材料の選択と準備

プラスチック原料から始まる。これは通常、ペレットの形か顆粒の形で梱包される。このような材料は通常、ABS、ポリプロピレン、ポリエチレン、ナイロンである。.

- ペレットのサイズ 2-5 mm

- 乾燥前の含水率: 0.02% -0.05%

- 乾燥温度: 80°C-120°C

- 乾燥時間: 2~4時間

適切な乾燥が重要です。成形品の気泡や表面の欠陥は、湿気によってもたらされることがあります。.

溶解と可塑化

プラスチックのペレットは乾燥され、強制的に投入される。 射出成形 マシーン。回転するスクリューを通り、高温の樽を通過する。.

- 樽の温度ゾーン: 180°C-300°C

- スクリュー速度: 50-300 RPM

- スクリュー圧縮比: 2.5:1 -3.5:1.

スクリューを回すとプラスチックが溶ける。物質は均質な液体の塊となる。溶融でさえ、成分の一貫性を提供します。.

注入フェーズ

プラスチックの溶融が完了すると、成形キャビティに押し込まれる。金型は大きな圧力で素早く規則正しく充填される。.

- 射出圧力: 800~2000バール

- 射出速度: 50-300 mm/s

- 注射時間: 0.5~5秒

適切な圧力制御により、ショートショットやフラッシュは使用しない。プラスチックの冷却が始まる前に金型全体を充填することを目的としています。.

梱包・保管段階

金型に充填し、圧力をかける。これは、室温で材料が収縮する過程を克服するためである。.

- 負荷圧力: インジェクションの流量は30~70%。.

- 持ち時間: 5~30秒

- 典型的な収縮率: 0.5%-2.0%

この工程は、部品の集中度と寸法を高める。また、内部ステントも減少する。.

冷却プロセス

射出成形は、冷却時間が最も長いプロセスである。その後、プラスチック物質は固化し、溶融する。.

- 金型温度: 20°C-80°C

- 冷却時間: 10~60秒

- 熱伝達効率: 60%-80%

熱の除去は、金型内の冷却溝によって行われます。適切な冷却は、表面の反りや欠陥をなくします。.

型開きと射出

冷却後、金型が開く。完成した部分はエジェクターピンやプレートを使って取り外す。.

- 型開き速度: 50~200mm/秒

- イジェクト力: 5-50 kN

- 排出時間: 1~5秒

排出:慎重に排出することで、部品にダメージを与えません。金型が閉じると、次のサイクルが始まります。.

サイクルタイムと生産量

トータルのサイクルタイムは、部品のサイズや素材によって異なる。.

- 平均サイクルタイム: 20~90秒

- 出力レート: 40 -180部品/時間。.

- 機械のクランプ力: 50~4000トン

サイクルタイムの短縮は生産性を高める。しかし、品質は常に維持されなければならない。.

プロセスの監視と制御

現代の機械では、センサーとオートメーションが採用されている。圧力流量と温度はこれらのシステムによってチェックされる。.

- 温度耐性: ±1°C

- 圧力耐性: ±5バール

- 寸法精度: ±0.02 mm

工程を監視することで、品質の一貫性が確保される。また、スクラップやダウンタイムも削減できます。.

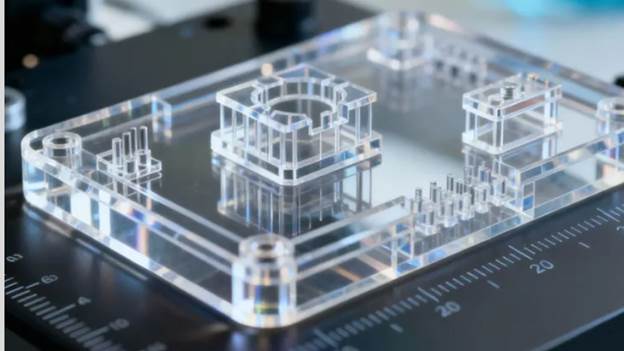

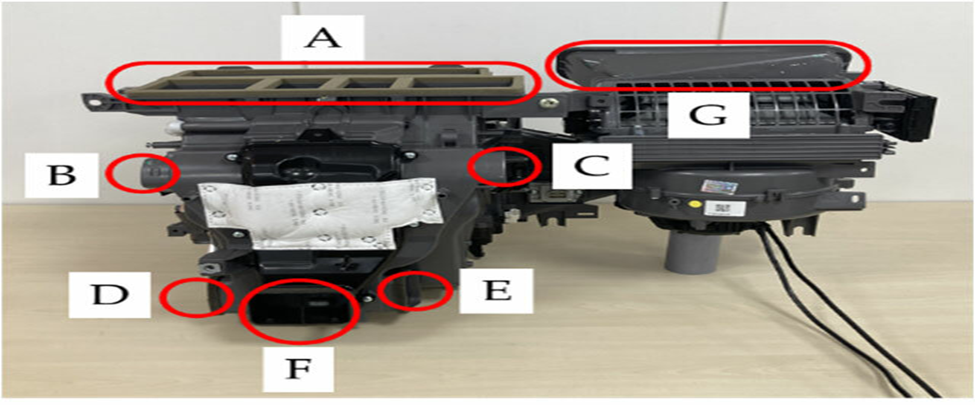

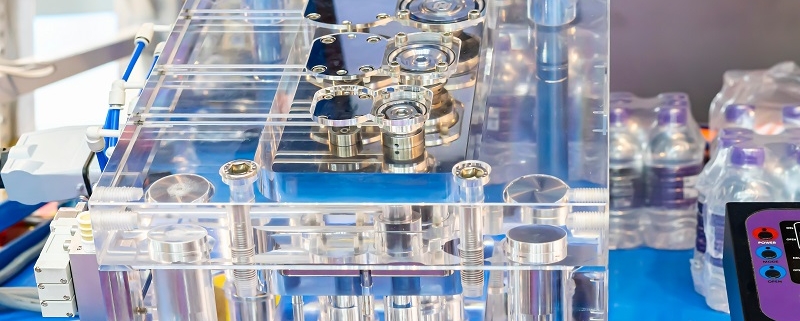

カビの成分の重要性

射出成形は金型の部品に左右される。金型の各要素には何らかの役割があります。成形、冷却、射出である。.

について プラスチック射出成形 部品は金型の正しい設計次第で成功すると考えられている。粗悪な金型は欠陥の原因となる。このような欠陥には、亀裂や不均衡な表面などが含まれます。一方、射出成形で作られた金型部品は、精度を確保するのに役立ちます。射出成形で作られた金型部品は、精度を確保するのに役立ちます。.

高品質のプロトラクトパーツを成形。メンテナンスコストも削減できる。そのため、より効果的で信頼できるものとなっている。.

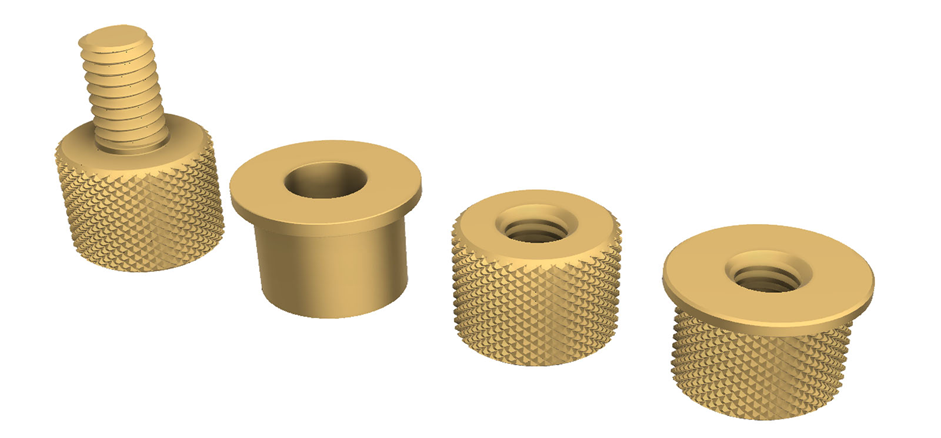

金型部品技術情報

金型部品は射出成形システムの最も重要な要素である。形状、精度、強度、表面品質をコントロールする。設計された金型部品がなければ、安定した生産はできません。.

コアとキャビティ

製品の最終的な形状を決定するのは、コアとキャビティである。外面はキャビティで構成される。コアは内部の特徴を構成する。.

- 寸法公差: ±0.01-0.03 mm

- 表面仕上げ: Ra 0.2-0.8 µm

- 典型的な鋼の硬度: 48-62 HRC

コアとキャビティの精度が高いため、欠陥を最小限に抑えることができる。また、部品の均一性も向上します。.

ランナーシステム

ランナーのシステムは、射出ノズルで溶融したプラスチックをキャビティに導く。フローバランスと充填速度に影響を与えます。.

- ランナーの直径: 2-8 mm

- 流速: 0.2-1.0 m/s

- 圧力損失の限界: ≤10%

適切なランナー設計により、材料の無駄を削減。また、均一な充填が可能です。.

ゲートデザイン

ゲートはキャビティ内のプラスチックの流れを調整します。部品の品質は、ゲートのサイズと種類に左右されます。.

- ゲートの厚さ: 部品厚みの50~80.

- ゲート幅: 1-6 mm

- せん断速度の限界: <100,000 s-¹

右ゲート設計により、ウェルドラインやバーンマークを排除。.

冷却システム

冷却トラックは金型を冷却するために使用される。このシステムは、サイクルタイムと部品の安定性に直接影響します。.

- 冷却水路の直径: 6~12ミリ

- チャンネルからキャビティまでの距離: 10-15mm。.

- 許容される最大温度差: < 5 °C.

冷却が容易なため、寸法精度が向上します。また、生産時間の短縮にもつながります。.

排出システム

冷却されると、部品は排出システム内に排出される。危害を加えないようにするためには、等量の力を発揮しなければならない。.

- エジェクターピンの直径: 2-10 mm

- ピン1本あたりのイジェクター力: 200-1500 N

- 排出ストロークの長さ: 5-50 mm

均一な排出により、亀裂や変形を排除。.

排気システム

注入時に空気がこもり、通気孔から抜けてしまうことがある。火傷や不完全充填は通気不良が原因。.

- ベントの深さ: 0.02-0.05 mm

- ベントの幅: 3-6 mm

- 最大空気圧: <0.1 MPa

十分な換気は、表面の品質と金型の寿命を向上させる。.

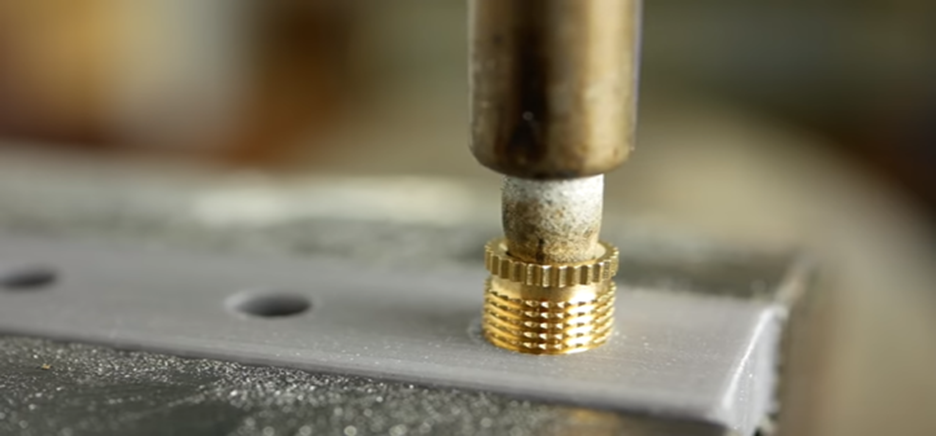

ベースとアライメント・コンポーネント 金型ベース

金型の底面がすべての部品を支える。ブッシングとガイドピンは、適切なアライメントを提供するために使用されます。.

- ガイドピンの公差: ±0.005 mm

- 金型底面の平坦度: ≤0.02 mm

- ライフサイクルの調整: 100万ショット以上.

アライメントを高くすることで、摩耗やバリが減少する。.

表2:主要プロセス・パラメーター

| パラメータ | 推奨範囲 | 単位 | 説明 | 代表値 | 備考 |

| バレル温度 | 180-300 | °C | 熱を加えてプラスチックを溶かす | 220-260 | 素材の種類による |

| 射出圧力 | 800-2000 | バー | 溶融プラスチックを金型に押し込む圧力 | 1000 | 部品のサイズと複雑さを調整 |

| 金型温度 | 20-120 | °C | 適切な冷却のための温度維持 | 60-90 | エンジニアリング・プラスチックの方が高い |

| 冷却時間 | 10-60 | おかわり | プラスチックが固まるまでの時間 | 25-35 | 肉厚による |

| サイクルタイム | 20-90 | おかわり | 成形サイクルあたりの合計時間 | 30-50 | 射出、パッキング、冷却を含む |

| イジェクト力 | 5-50 | kN | 金型から部品を取り外す力 | 15-30 | 部品の損傷を防ぐこと |

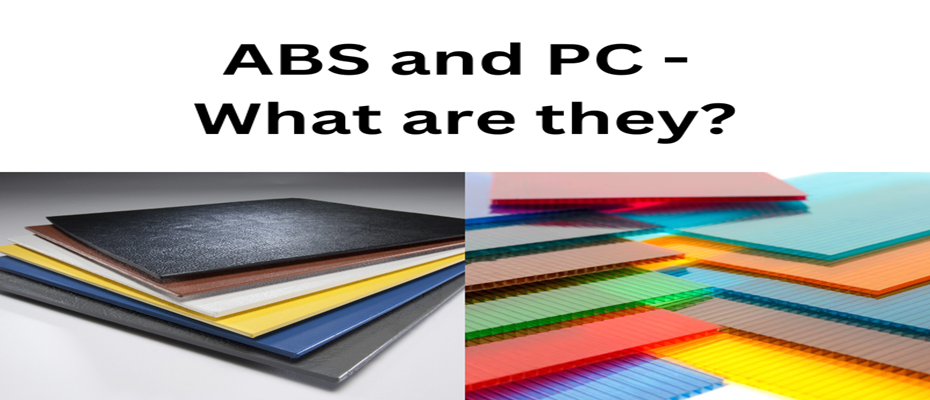

原材料 射出成形

素材選びは非常に重要だ。最終製品の品質、安定性、見通し、価格に影響します。適切なプラスチックを選択することは、部品が機能し、適切に印刷されることを保証するために必要です。.

熱可塑性材料

最も普及している素材は、溶かして何度も再利用できることから熱可塑性プラスチックである。ABS、ポリプロピレン、ポリエチレン、ポリスチレンなどが広く使われている。ABSは衝撃に強く丈夫で、200~240℃で溶ける。ポリプロピレンは160 °Cまたは170 °Cで溶ける。ポリエチレンの融点は120 °Cから180 °Cで、耐湿性製品に適している。.

エンジニアリングプラスチック

高強度部品や耐熱部品には、ナイロン、ポリカーボネート(PC)、POMなどのエンジニアリング・プラスチックが使用される。ナイロンは220℃~265℃で溶融し、歯車や機械部品に使用される。ポリカーボネートは260 °Cから300 °Cで溶ける強く透明なポリマーである。POMの溶融温度は165 °C~175 °Cで、部品に使用される。.

熱硬化性プラスチック

熱硬化性プラスチックは永久的に硬化するため、成形後の再溶解が難しい。150℃〜200℃で溶融し、電気部品などの高温用途に利用される。.

添加剤と充填剤

素材は添加物によって強化される。ガラス繊維(10% -40%)は強度を高め、ミネラルフィラー(5% -30%)は収縮率を下げ、UV安定剤(0.1-1%)は日光を遮蔽する。これらの補助成分は長持ちし、より良く機能する。.

材料選択の要件

材料の選択は、温度、強度、化学的な対立、湿気、コストなどの点で要因に左右される。適切な選択は、長持ちし、正確で高品質な製品をもたらし、ミスや無駄を減らす。.

表3:材料特性

| 素材 | 溶融温度 (°C) | 金型温度 (°C) | 射出圧力(bar) | 引張強さ (MPa) | 収縮率(%) |

| ABS | 220-240 | 60-80 | 900-1500 | 40-50 | 0.5-0.7 |

| ポリプロピレン(PP) | 160-170 | 40-70 | 800-1200 | 30-35 | 1.0-1.5 |

| ポリエチレン(PE) | 120-180 | 20-50 | 700-1200 | 20-30 | 1.5-2.0 |

| ポリスチレン(PS) | 180-240 | 50-70 | 800-1200 | 30-45 | 0.5-1.0 |

| ナイロン(PA) | 220-265 | 80-100 | 1200-2000 | 60-80 | 1.5-2.0 |

| ポリカーボネート(PC) | 260-300 | 90-120 | 1300-2000 | 60-70 | 0.5-1.0 |

| POM(アセタール) | 165-175 | 60-80 | 900-1500 | 60-70 | 1.0-1.5 |

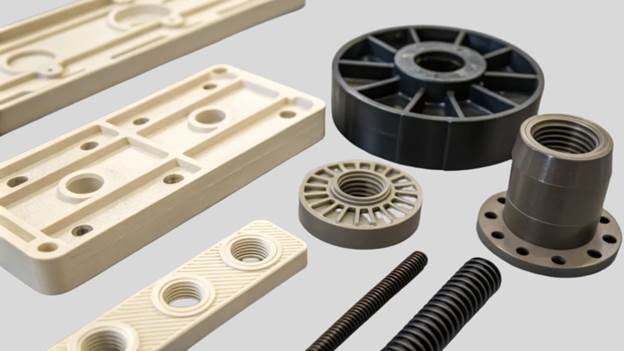

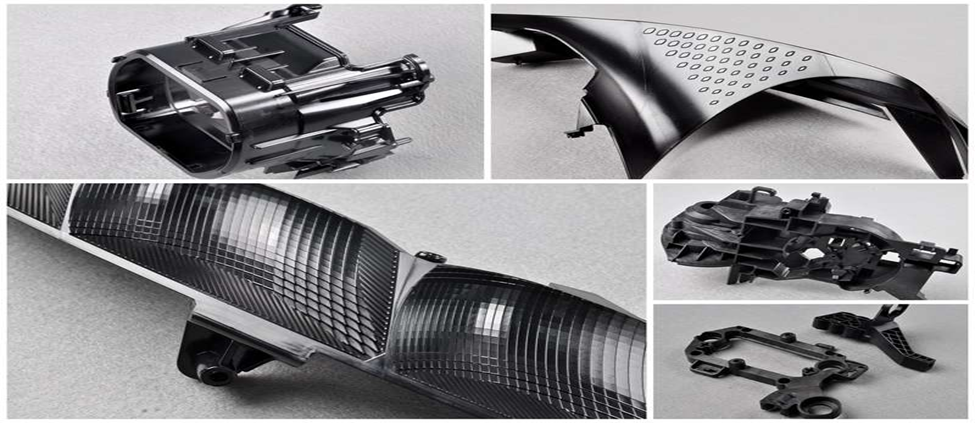

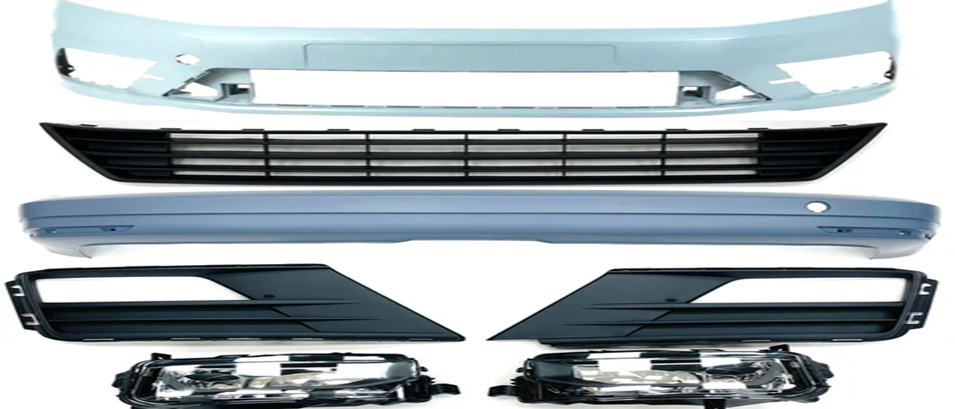

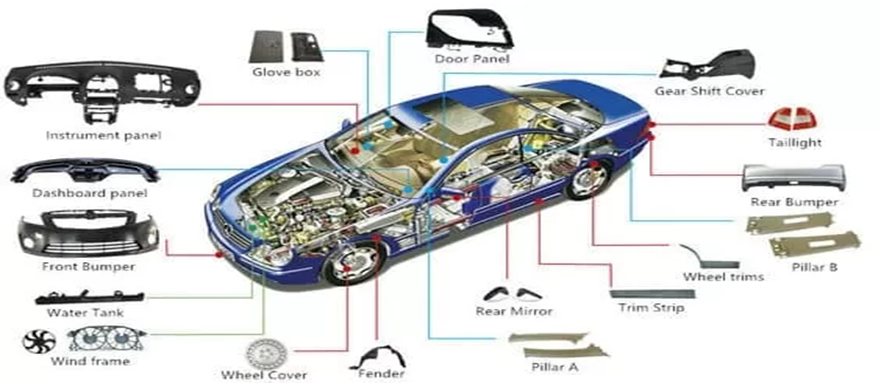

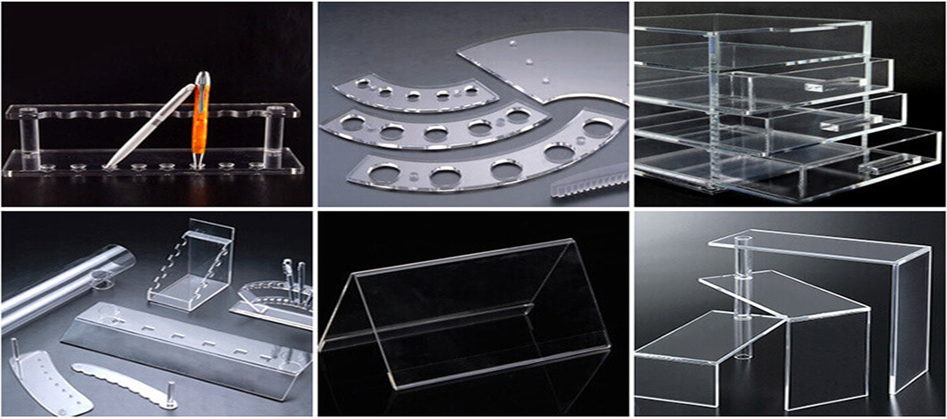

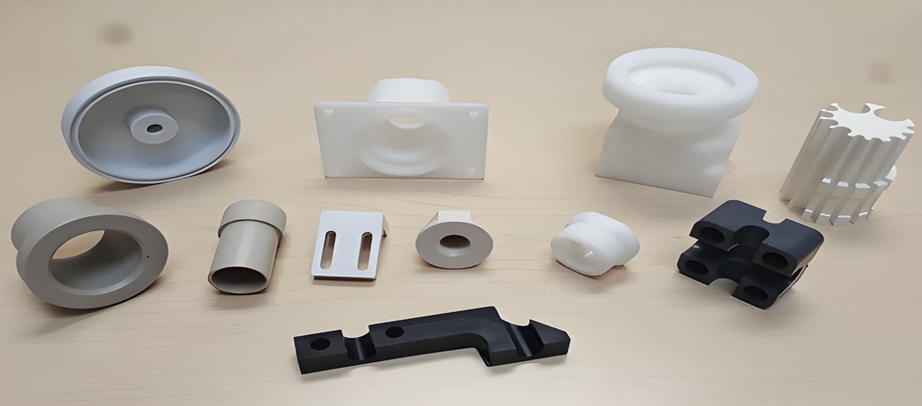

プラスチック射出成形プロセスで製造される部品

プラスチック射出成形は、様々な分野で使用される数多くの部品を作り出すプロセスである。この工程は精密で耐久性があり、大量生産が可能である。この方法で製造される代表的な部品の例を以下に示す。.

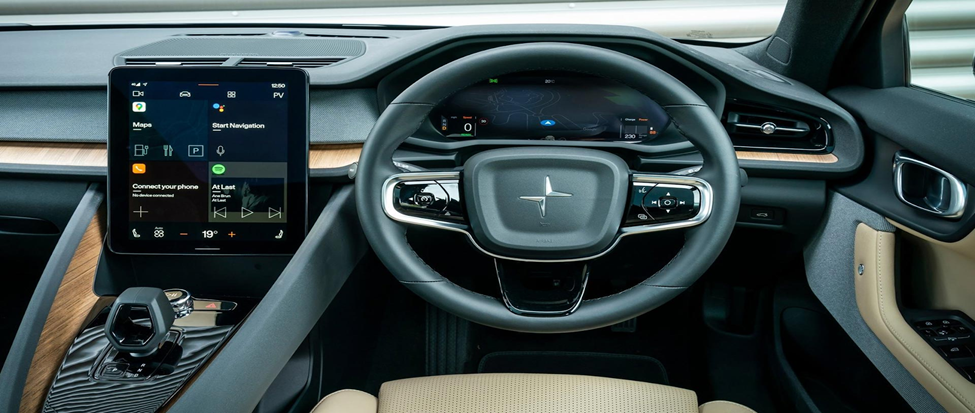

自動車部品

- ダッシュボード

- バンパー

- 通気口

- ドアパネル

- シフトノブ

- 燃料系統部品

- インテリアトリム

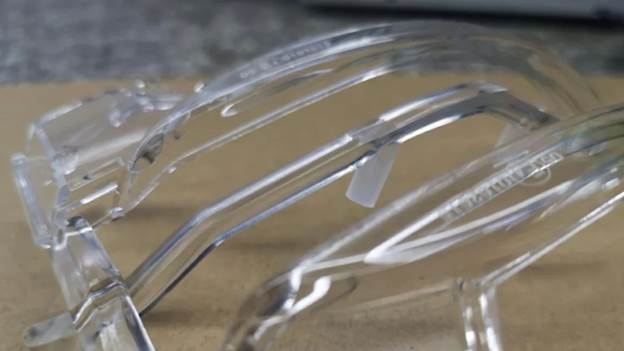

医療部品

- 注射器

- チューブコネクター

- 手術器具

- IV成分

- 医療機器ハウジング

- 使い捨て医療器具

電子部品

- 機器用ハウジング

- スイッチとボタン

- ケーブルクリップとワイヤーホルダー

- コネクターとプラグ

- キーボードのキー

- 回路基板用エンクロージャー

パッケージ製品

- ボトルと瓶

- ボトルのキャップと栓

- 食品容器

- 化粧品容器

- 蓋とシール

- 収納ボックス

消費財・工業製品

- おもちゃとフィギュア

- 家庭用具

- 家電部品

- 建築用金具

- 正確なクリップとファスナー。.

- 産業機械部品

デザインと精度

デザインは成功に大きく貢献する。効果的な金型は製品の品質を高めます。生産時のエラーも最小限に抑えることができます。.

のプロセスの各部分。 プラスチック射出成形 厳密な寸法が要求される。性能は小さなミスによって左右されます。射出成形金型部品の作成が公差を厳しく設計されるのはこのためです。設計には最先端のソフトウェアが採用されることが多い。.

強さは優れたデザインによっても強化される。外観も向上する。エンドアセンブリの優れたフィッティングを保証します。.

産業用途

射出成形は、高速で正確、しかも経済的である。非常に高い精度で同一の部品を大量生産することができる。.

自動車産業

自動車分野では、ダッシュボード、バンパー、吹き出し口、内装パネルなどがプラスチック射出成形部品で作られている。これらの部品は、強力で軽く、耐熱性でなければならない。特に、安全性と品質の問題を防ぐために、形状が正確で均一な成形によって行われる。.

医療業界

医療分野 注射器、チューブのコネクター、手術器具は射出成形で作られる。多くの精密さと衛生面が必要とされる。特に、プラスチック射出成形部品は、医療グレードのプラスチックを使用することができ、射出成形金型部品を使用して、精度と滑らかさを確保することができます。.

エレクトロニクス産業

ハウジング、コネクター、スイッチ、ケーブルクリップはすべて、射出成形によってエレクトロニクス産業で生産されている。プラスチック射出成形部品は壊れやすい回路を固定し、射出成形金型部品は部品を完全に適合させるために必要である。.

包装業界

射出成形はまた、ボトル、容器、キャップ、および閉鎖の包装に適用されます。プラスチック射出成形の部品は、必要な形状やサイズを与えるために使用され、射出成形の部品は、最小限の無駄を作成することにより、最短時間で大量に生産するために使用されます。.

その他の産業

消費財、玩具、建築、航空宇宙も射出成形される。その柔軟性と精度は、シンプルな家庭用品から複雑な技術部品まで、ほぼすべてのプラスチック製品に適合する能力を与えている。.

品質管理とテスト

製造には品質管理が必要である。すべての部品は設計要件を満たすように乾燥されるべきである。テストは安全性と性能の尺度である。.

プラスチック射出成形部品は、目視検査と機械的検査を受けます。これらの検査により、欠陥が早期に発見される。同時に、射出成形部品の摩耗や損傷の検査も行われる。頻繁な検査により、生産不良の失敗をなくします。.

優れた品質管理は顧客の信頼を高める。また、無駄や出費を最小限に抑えることができる。.

射出成形の長所

射出成形には数多くの利点がある。迅速な生産が可能である。また、繰り返し生産も可能です。.

プラスチック射出成形 部品はダイナミックで軽い。大量生産が可能である。一方、自動化は金型部品の射出成形によって支えられている。これにより、人件費とミスのコストが削減される。.

また、このプロセスは環境に優しい。スクラップは再利用できる。これは環境保護にも貢献する。.

課題と解決策

射出成形は、他の工程と同様、難しいものである。金型の摩耗だけでなく、材料の問題もある。好ましくない環境は欠陥につながる。.

プラスチック射出成形部品」の適切な取り扱いがない場合、部品の欠陥が評価される可能性がある。このようなリスクは、適切な訓練によって最小限に抑えることができる。同時に、射出成形に使用される金型部品は、定期的にメンテナンスされなければならない。これにより長寿命が保証される。.

現代のテクノロジーは、多くの問題に対処するのに役立つだろう。自動化とモニタリングによって効率は向上する。.

射出成形の未来

射出成形の未来は明るい。新素材の開発もある。スマート・マニュファクチャリングが現実のものになりつつある。.

プラスチック射出成形部品は改良される。より大きく、より軽くなる。同時に、射出成形部品にはより良い素材とコーティングが施される。これによって寿命が延びる。.

この業界は依然として革新的である。競争力のある企業は、変化する企業である。.

中国の役割

中国は世界の射出成形市場に大きく貢献している。プラスチック射出成形部品の最大メーカーのひとつであり、射出成形金型部品の販売業者でもある。製造業は非常に多様化しており、大量生産だけでなく小規模生産も行われている。.

中国の工場では、部品の製造に高精度の機械と熟練した労働力が使われている。多くの国際企業が中国メーカーに依存しているのは、彼らが品質を落とすことなく費用対効果の高いソリューションを提供してくれるからである。.

その上、中国はイノベーションのリーダーでもある。効率を高めるために新しい材料、金型、自動化手法を生み出している。優れたサプライチェーンと高い生産能力が、射出成形品の世界需要を満たす主要プレーヤーとしての地位に貢献している。.

Sincere Techを選ぶ理由

私たちは、最高級のオンタイムデリバリーをお約束 プラスチック射出成形部品プロンプトが表示さに裏打ちされ、慎重アフターサービス。私たちは、最高級のオンタイムデリバリーをお約束 プラスチック射出成形部品プロンプトが表示さに裏打ちされ、慎重アフターサービス。.

弊社は経験豊富で資格のあるエンジニアと技術者のグループを持っており、近代的な機械と新しい方法の適用により、高品質で手頃な価格のソリューションを提供しています。私たちは、材料の選択、金型の設計などのすべての細部に細心の注意を確保し、我々は各バッチで同じ品質を持っているようにしています。.

Sincere Techは、信頼、プロフェッショナリズム、顧客満足度を高く評価しているため、クライアントから好評を得ています。私たちは個々のお客様と協力し、お客様の特別なニーズを把握し、そのニーズに対するソリューションを提供します。また、納期厳守、技術支援、絶え間ない改善というコンセプトのもと、射出成形業界で際立った存在となっています。.

Sincere Techはプラスチック射出成形において、細かな部品から大量生産まで、卓越した技術を提供する会社です。Sincere Techでは、単に部品を提供するだけでなく、お客様の成功と成長のために尽力するチームを提供します。.

plas.coのサービスや製品についてもっと知りたい方は、plas.coにアクセスして、なぜ私たちが世界中のお客様に選ばれているのかをご覧ください。.

結論

射出成形は堅実な生産プロセスである。射出成形は世界の数多くの産業を支えています。その主な強みは、精度、スピード、品質です。.

プラスチック射出成形部品は、今でも日常生活に欠かせないものだ。最も単純な部品から複雑な部品まで、様々なニーズに応えるのに役立っている。一方、射出成形金型部品は、製造の効率的な流れと同じ結果を保証します。.

射出成形は、適切な設計とメンテナンスがあれば、今後も増え続けるだろう。また、射出成形は現代の生産に欠かせない要素であり続けるだろう。.