La producción moderna apuesta por la eficacia y la precisión. Algunas de las técnicas que se utilizan son el moldeo por inyección asistida por gas. El moldeo por inyección asistida por gas es un método tecnológico de producción que ayuda a fabricar piezas de plástico ligeras, duraderas y complejas. Las secciones huecas se crean inyectando gas inerte en el molde, lo que reduce la cantidad de material utilizado y acorta la duración del ciclo.

El resultado es el aumento de la precisión dimensional, la disminución de las distorsiones y la capacidad de realizar diseños innovadores. El moldeo por inyección asistida por gas es útil en la industria del automóvil, la industria del mueble, la industria electrónica y las industrias de productos de consumo, donde se necesita una producción rentable con alta calidad. Los proveedores fiables de moldeo por inyección con gas centinela garantizan un resultado regular. Con la producción imperante, la mayoría de los fabricantes hacen uso de productos moldeados por inyección asistida por gas, lo que permite a los fabricantes lograr eficiencia, resistencia y estética.

¿Qué es el moldeo por inyección asistida por gas?

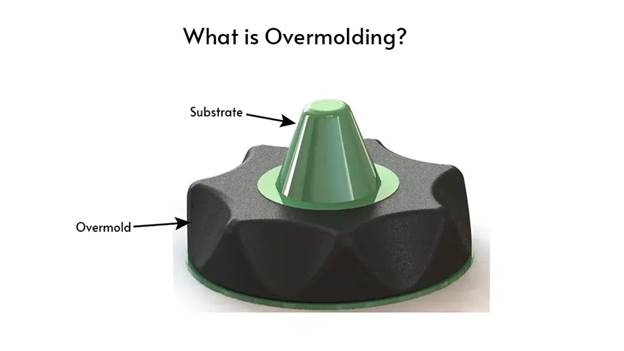

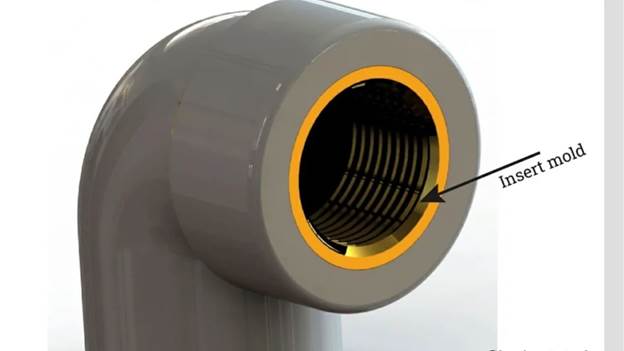

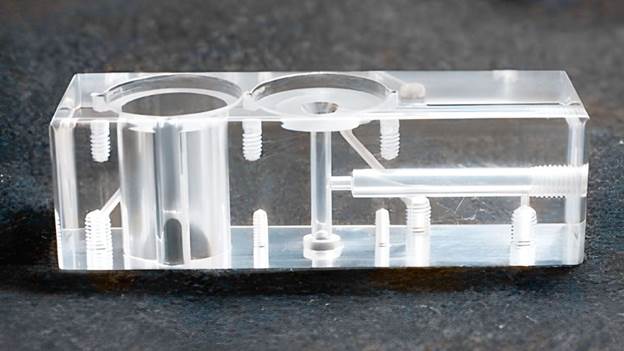

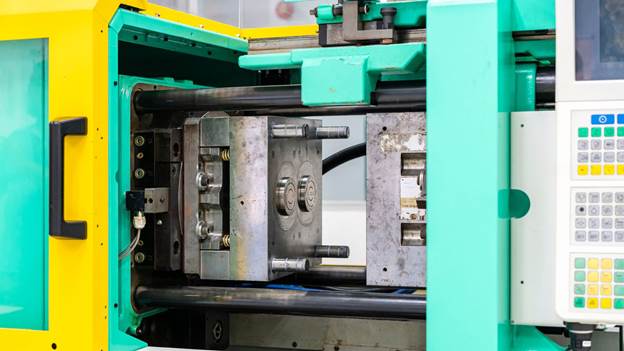

Asistencia de gas moldeo por inyección es el proceso en el que se inyecta gas inerte (normalmente nitrógeno) en el molde durante el proceso de inyección del plástico. El gas fuerza el plástico caliente contra las paredes delgadas o huecas del componente, creando un hueco en su interior. Esta técnica ahorra material, aumenta la precisión de las dimensiones y minimiza el alabeo.

El proceso es más apropiado en las secciones que son gruesas o cuyas secciones tienen largos recorridos de flujo. Se utiliza mucho en la fabricación de automóviles, muebles y productos de consumo. La calidad y la fiabilidad estarían garantizadas por la elección de proveedores adecuados de moldeo por inyección asistida por gas.

Funcionamiento del moldeo por inyección asistida por gas

Comienza igual que el moldeo por inyección convencional, ng el que se inyecta plástico en un molde. Una vez que la cavidad del molde está parcialmente llena, se inyecta gas a presión en algunas de las zonas. Este gas hace que el plástico líquido sea forzado hacia el exterior para formar canales huecos, ls pero endurece la superficie.

El método reduce la tensión en las piezas más gruesas, elimina los hundimientos y uniformiza el grosor de las paredes. El resultado es una pieza de alta calidad, dimensionalmente más estable, ligera y resistente. Se trata de características funcionales y estéticas para los fabricantes de productos, como el moldeo por inyección asistida por gas.

Aplicaciones del moldeo por inyección asistida por gas: El moldeo por inyección asistida por gas es una técnica de fabricación flexible que se adopta en la mayor parte de las industrias. Se pueden crear formas huecas o intrincadas con menos esfuerzo, por lo que resulta adecuado tanto para fines útiles como decorativos.

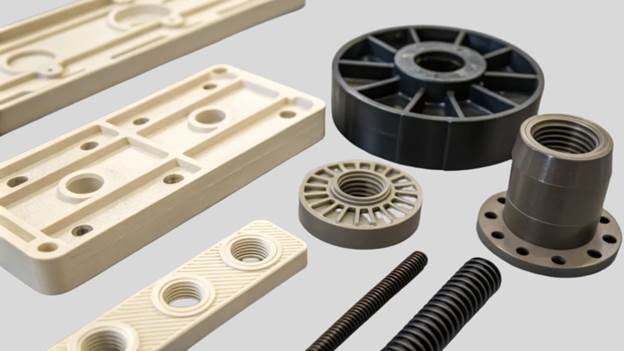

Automoción Los fabricantes de automóviles realizan el moldeo por inyección asistida por gas industrial de paneles interiores, tiradores de puertas y piezas estructurales. El procedimiento lo hace ligero sin perder la resistencia que está ligada a la eficiencia de combustible y el rendimiento.

Muebles y productos de consumo

El moldeo por inyección asistida por gas se utiliza para crear secciones huecas que se crean en piezas de plástico de muebles, electrodomésticos y herramientas. Los componentes ligeros, como respaldos de sillas, asas y carcasas, constituyen una forma eficaz de producción.

Equipamiento industrial

Los robots y las máquinas suelen necesitar piezas de plástico resistentes y de cierto tamaño. Los productos fabricados a base de moldeo por inyección asistida por gas tienen durabilidad, grosor de pared estándar y resistencia al alabeo.

Electrónica El moldeo por inyección asistida por gas se utiliza en la fabricación de productos electrónicos de consumo, carcasas de herramientas y otros dispositivos que requieren un aspecto fuerte y atractivo, por tanto, con un bajo consumo de material.

Otras aplicaciones

También se utiliza en artículos deportivos, juguetes y envoltorios. Los fabricantes recurren a los servicios de los proveedores de moldeo por inyección asistida por gas, que tienen la oportunidad de producir piezas del tamaño y la calidad dados.

Una vez conocidas estas aplicaciones, las empresas pueden experimentar todas las ventajas del moldeo por inyección de gas auxiliar para fabricar productos ligeros y asequibles.

Material utilizado

Termoplásticos: Los termoplásticos son los materiales más utilizados en el moldeo por inyección asistida por gas. Algunos materiales pueden trabajarse y unirse fácilmente en el proceso asistido por gas, como el polipropileno (PP), el polietileno (PE), el ABS y el policarbonato (PC). Estos plásticos son convenientes en la fabricación de productos moldeados por inyección ligeros y resistentes.

Plástico reforzado: Los plásticos reforzados con fibra de vidrio de nailon o polipropileno son además resistentes y rígidos. Se utilizan en áreas que exponen el componente a un alto grado de tensión o carga y, por lo tanto, irán bien con las piezas de automoción o industriales producidas durante el moldeo por inyección asistida por gas.

Polímeros especiales: En algunos casos, se utilizan polímeros especiales que se caracterizan por una gran resistencia al calor o a los productos químicos. Estos materiales determinan los requisitos del producto en términos específicos que garantizan su rendimiento y longevidad. La inclusión del moldeo por inyección asistida por gas, que ya ha funcionado anteriormente en la industria, ayudará en la elección del material adecuado que se utilizará en cualquier aplicación.

Selección de materiales: El medio empleado debe tener excelentes características de flujo, estabilidad térmica y compatibilidad con la inyección de gas. La selección adecuada del material es bastante crítica para reducir los defectos, la resistencia y la eficacia de las piezas utilizadas en el proceso de moldeo por inyección asistida por gas.

Técnicas

Inyección recíproca mediante canales de gas

En él, las piezas huecas se fabrican por bombeo en el molde en algunas zonas. Ahorra en el consumo de materiales y proporciona uniformidad en el grosor de las paredes. También se utiliza mucho en la producción de compuestos ligeros y resistentes mediante moldeo por inyección asistida.

Regulador de presión de gas adaptable

La presión del gas también puede ajustarse en el proceso de moldeo para manipular el flujo del material de forma mejorada. Así se evitan las marcas de hundimiento, se mejora el acabado de la superficie y se fortalece el arte. Y lo que es más importante, los casos de alta calidad asistida por gas moldeado por inyección productos.

Inyección secuencial de gas

La inyección secuencial de gas consiste en inyectar gas en distintas fases del proceso de moldeo. El procedimiento garantizará la optimización del flujo de materiales asumiendo la forma de una X completa, y la reducción del número de defectos. También se debe acudir a los proveedores, ya que están familiarizados con el moldeo por inyección asistida por gas, de forma que pueda realizarse con precisión.

Métodos de refrigeración de última generación

El moldeo asistido por gas con sistemas de refrigeración avanzados es útil para solidificar rápidamente los componentes y reducir el tiempo de ciclo. Esto favorece la productividad y no obstaculiza el diseño de la pieza.

Ventajas del moldeo por inyección asistida por gas

Comparando el moldeo tradicional y el llamado moldeo por inyección asistida por gas, se pueden señalar varias ventajas:

Ahorro de material

Las secciones huecas también consumen menos plástico y reducen tanto los gastos como el impacto medioambiental.

Menos deformaciones y marcas de hundimiento

El moldeo asistido por gas minimiza la mayoría de los defectos habituales, como las marcas de hundimiento o las deformaciones de la superficie, gracias a la distribución uniforme del material.

Piezas de encendedor

Existen estructuras huecas que permiten crear componentes ligeros sin reducir su resistencia.

Producción más rápida

Asociado a un menor consumo de material y a un mejor flujo se produce una reducción de los tiempos de ciclo; algo que resulta más aceptable para los fabricantes.

Mayor margen de maniobra en el diseño

Es posible crear formas complejas, así como añadir partes más gruesas sin reducir la calidad ni encarecerla.

Consideraciones sobre el diseño

El moldeo por inyección asistida desarrollado con gas también debe planificarse bien para maximizar el proceso.

Selección de materiales todos los plásticos pueden moldearse con gas. Los diseñadores deben utilizar materiales que fluyan y se adhieran fácilmente a la inyección de gas.

Espesor de pared

Las paredes deben tener el mismo grosor. Los espacios abiertos deben colocarse en posiciones estratégicas para crear solidez y funcionalidad.

Colocación del canal de gas: La ubicación en del canal de as es lo más importante. Cuando se colocan en una posición incorrecta pueden dejar obturaciones a medio rellenar, puntos débiles o defectos estéticos.

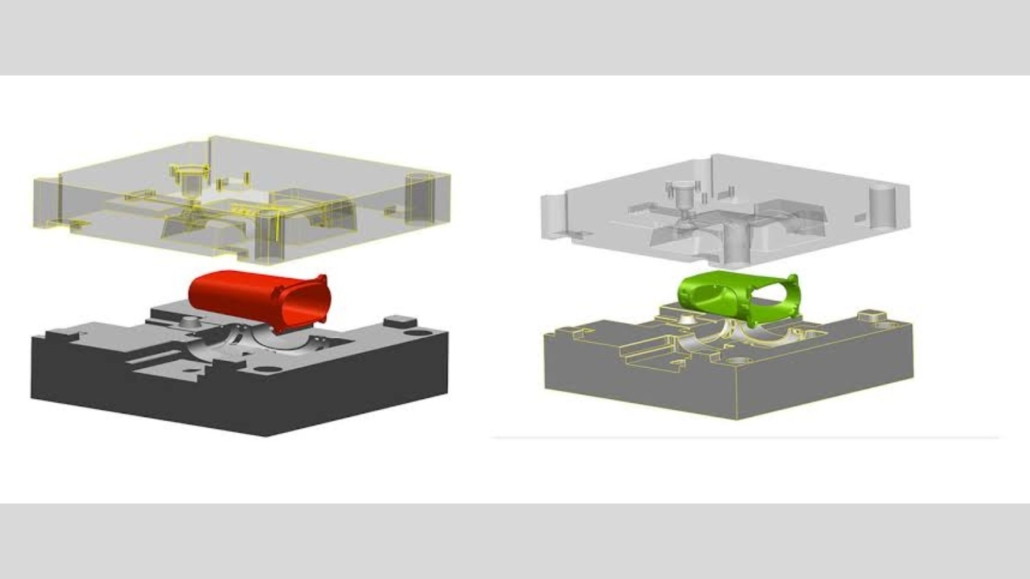

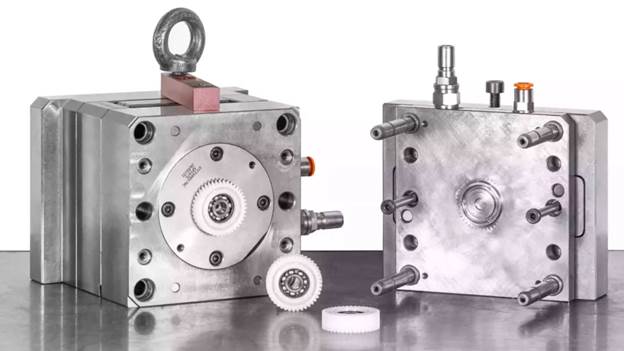

Diseño de moldes

Debe ser posible el paso de plásticos y gases a los moldes. Las puertas estarían bien ventiladas y diseñadas para garantizar que la producción se hace efectiva y se minimizan los defectos.

Estas especificaciones de diseño son el medio seguro de obtener resultados de alta calidad y fiabilidad en el moldeo por inyección asistida por gas.

Coste y eficiencia de la producción

Coste y eficacia de la producción El moldeo por inyección asistida por gas es muy económico en comparación con los procesos tradicionales en términos de moldeado, en detrimento de los gastos y de la velocidad de producción de los productos. Se ahorra en el coste de material porque las piezas son espacios huecos que son buenos y económicos.

El proceso permite que el plástico fundido fluya libremente, lo que ahorra tiempo de enfriamiento. Esto permitirá a los fabricantes producir piezas a un ritmo más rápido sin comprometer la calidad. Las empresas que fabrican los artículos mediante la producción de productos moldeados por inyección asistida por gas tienen la ventaja de ser más rápidas, y los resultados son consistentes.

La cooperación con los expertos que proporcionan el proceso de moldeo por inyección asistida por gas reduce el número de manipulaciones y recogidas manuales, lo que también reduce los costes de mano de obra. Esto es muy eficaz en términos de ahorro de material, disminución de los ciclos, así como de defectos, aunque los moldes sean más complicados al principio.

Errores comunes que hay que evitar

Los errores que pueden interferir en la calidad y la eficacia del producto son varios en el moldeo por inyección asistida por gas. El problema de la presión incorrecta del gas es el más común. La presión excesiva o insuficiente puede provocar deformaciones en los componentes o defectos.

Otro error es la mala canalización de los gases. Cualquier desalineación puede dar lugar a un llenado parcial o a paredes lisas que debilitarán los productos llenados mediante moldeo por inyección asistida por gas.

El problema de la inadaptación de los materiales utilizados también es bastante común. Algunos plásticos no responden bien a los procesos asistidos por gas, lo que provoca defectos o una mala unión.

Ignorar las directrices de diseño, es decir, el grosor de la pared y la geometría de la pieza, también puede ser problemático. Los componentes pueden doblarse, hundirse o sufrir tensiones.

Los siguientes errores podrían eliminarse mediante la colaboración con proveedores experimentados en moldeo por inyección asistida por gas, la consideración de las directrices de diseño y proceso adecuadas y la garantía de una producción de alta calidad de forma constante.

Identificación de los proveedores adecuados de moldeo por inyección con gas auxiliar

El éxito del moldeo por inyección asistida por gas depende de la elección del socio adecuado. Los esfuerzos con proveedores bien establecidos son la garantía de piezas de calidad y procesos de fabricación ininterrumpidos.

Seleccione la asistencia de gas moldeo por inyección proveedores que tienen una historia de éxito en la fabricación de productos moldeados por inyección de gas asistido de la misma naturaleza, similares a su proyecto. Pueden evitar defectos y mejorar su eficiencia con la ayuda de su experiencia en el diseño de los moldes y la selección del material utilizado.

El proveedor también debe proporcionar una guía de optimización del proceso, como la presión del gas, los canales de posicionamiento y los tiempos de ciclo. Esto puede aplicarse a la reducción de desperdicios e imprecisiones en la producción.

Los proveedores de calidad invierten en sistemas de control de calidad y nuevos equipos. Proporcionan resultados de garantía, un ritmo más rápido y rentabilidad en los programas de moldeo por inyección asistida por gas.

Tendencias futuras

Es el futuro del moldeo por inyección asistida por gas, que depende de las innovaciones y la eficacia. Los fabricantes buscan materiales más nuevos, resistentes, ligeros y duraderos. Son tecnologías que dan lugar a productos de calidad moldeados por inyección asistida por gas.

La otra tendencia importante es la de la automatización. Los robots y los sistemas de IA se encargan cada vez más de la inyección de gas y la manipulación de moldes, y erradican los errores y agilizan el proceso de producción. Los proveedores de gas con experiencia en moldeo por inyección también están adoptando estas tecnologías para mantenerse a la altura de la competencia.

También se tiene en cuenta la sostenibilidad. El consumo de menos materiales, el reciclado de plásticos y el ahorro de energía son elementos de fabricación respetuosos con el medio ambiente en la fabricación del moldeo por inyección ecológico denominado moldeo por inyección asistido por gas.

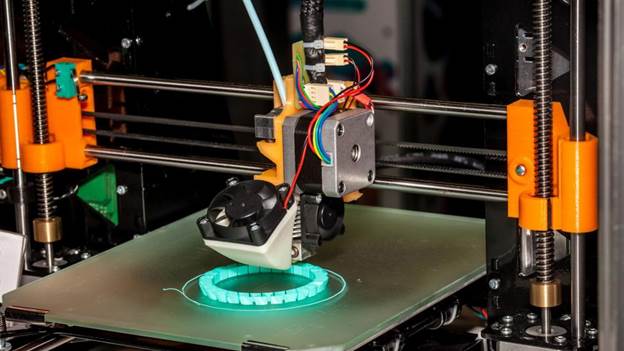

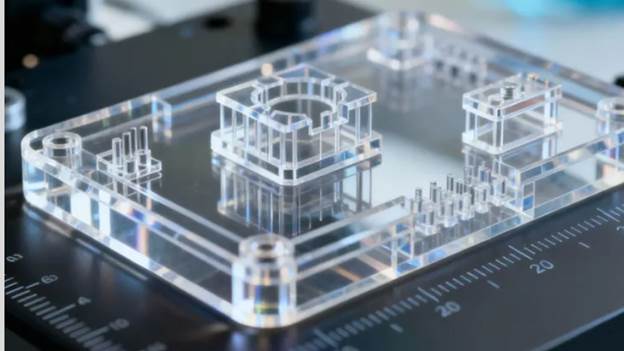

Esto se está mejorando con la incorporación de la impresión 3D, que amplía las posibilidades de creación rápida de prototipos y producción por lotes. Esto ayuda a los diseñadores a experimentar con formas complejas a bajo coste y en el menor tiempo posible; de este modo, el moldeo por inyección asistida por gas es más productivo en la producción moderna.

Conclusión

Asistido por gas moldeo por inyección puede ofrecer a los fabricantes un enfoque viable para producir componentes ligeros, complicados y robustos. Las empresas están en condiciones de tomar la decisión correcta, sabiendo cómo funciona, sus ventajas y de qué manera debe diseñarse. La elección de proveedores fiables de moldeo por inyección asistida por gas implicaría que el estándar de los productos moldeados por inyección asistida por gas sería el mismo en todas las industrias. La disminución de la cantidad de material utilizado se traduce en un aumento de la velocidad de producción y de la capacidad de realizar cambios en los diseños, lo que aumenta la popularidad de la técnica que se convierte en una forma bastante necesaria de la producción moderna.